Crushing station pit digging method

A crushing station and foundation pit technology, which is applied in blasting, earthwork drilling, open-pit mining, etc., can solve problems such as low construction efficiency, many blasting times, and poor blasting effects, and achieve reduced construction time, reasonable economy, and high technology Feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

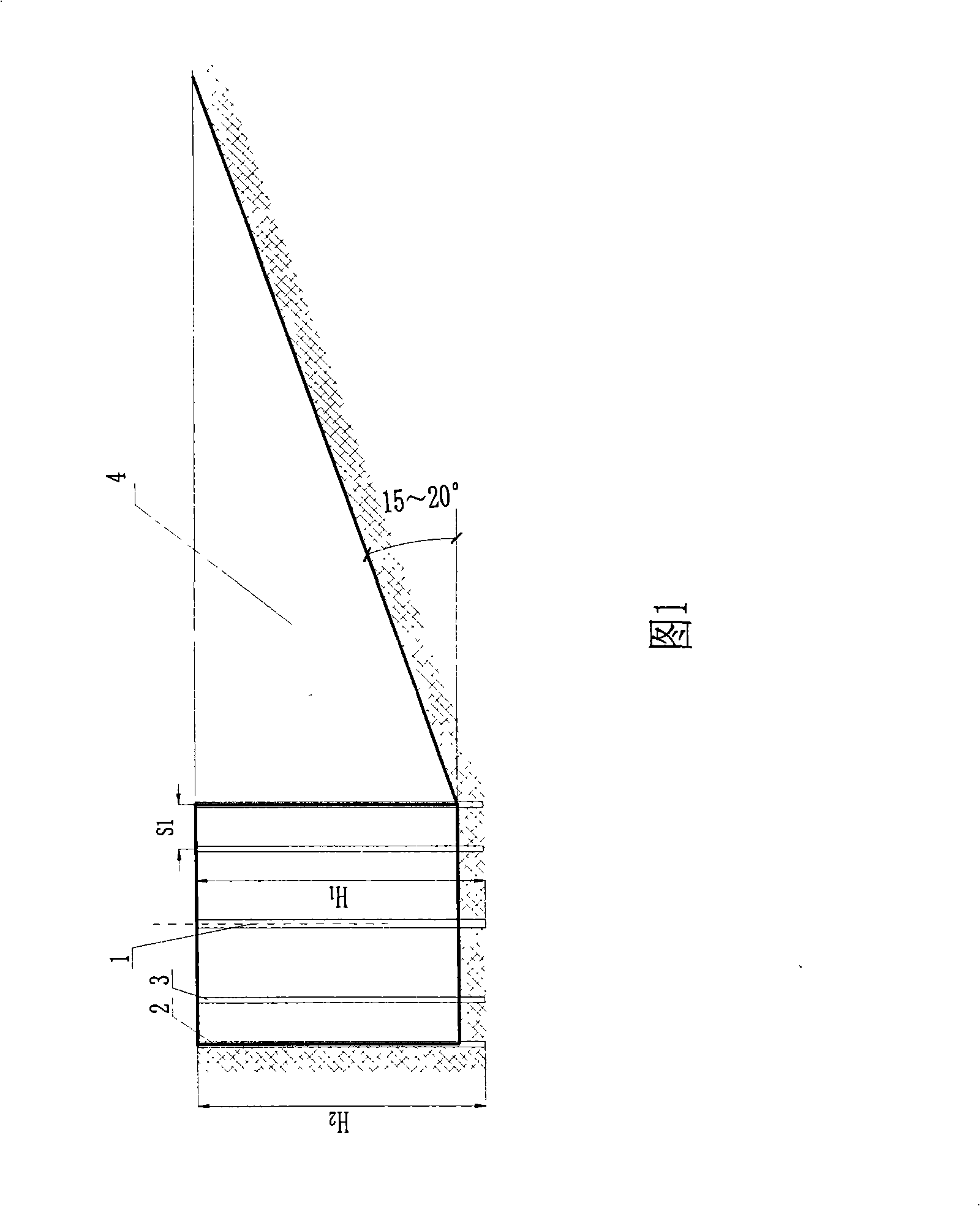

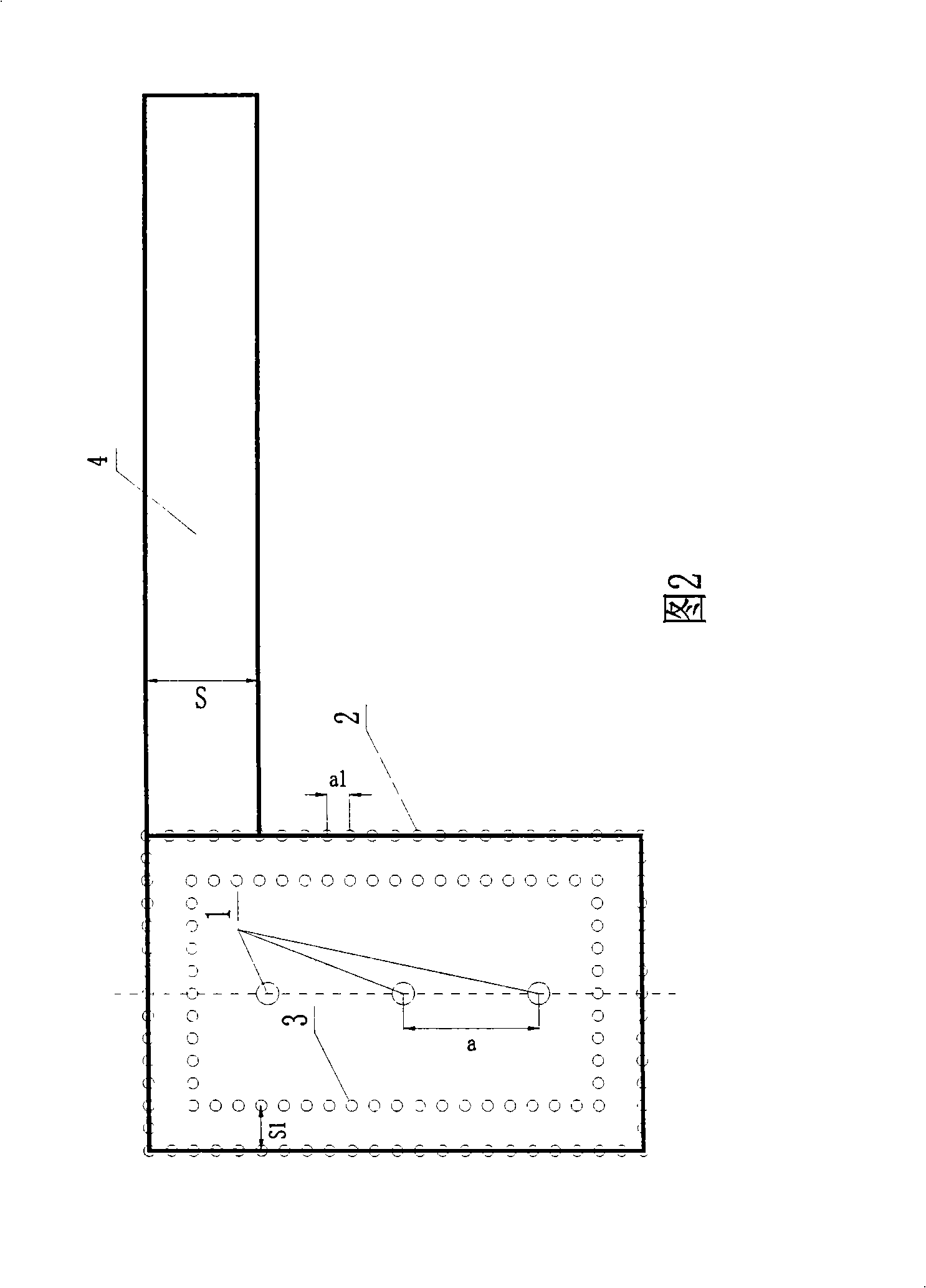

[0075] As shown in Figures 1 and 2, the technical solution adopted in the present invention includes the perforation of the blast hole, the blasting and the deslagging process after the blasting.

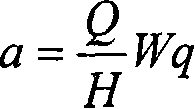

[0076] 1. Perforation: The blast hole perforation of the present invention includes the perforation process of pre-splitting holes, pre-splitting auxiliary holes, and main blast holes;

[0077] a) Pre-split holes

[0078] In order to reduce the impact of medium and deep hole blasting on the side wall of the foundation pit of the crushing station and reduce the amount of earth and rock, a slope drilling rig (or down-the-hole drilling rig) is used to penetrate the pre-splitting hole at the edge of the foundation pit of the crushing station. A crack is formed on the edge of the foundation pit of the crushing station, so that the part of the foundation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com