Two-dimensional coding normalization mask target combination and its alignment method and aligning system

A two-dimensional coding and alignment mark technology, which is applied in optics, instruments, photolithography process of pattern surface, etc., can solve the problems of large light transmission area, small capture range, increase imaging area, etc., to improve stability and accuracy , the effect of increasing the capture ability and the detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The combination of two-dimensional coded normalized alignment marks of the present invention and its alignment method and alignment system will be further described in detail below.

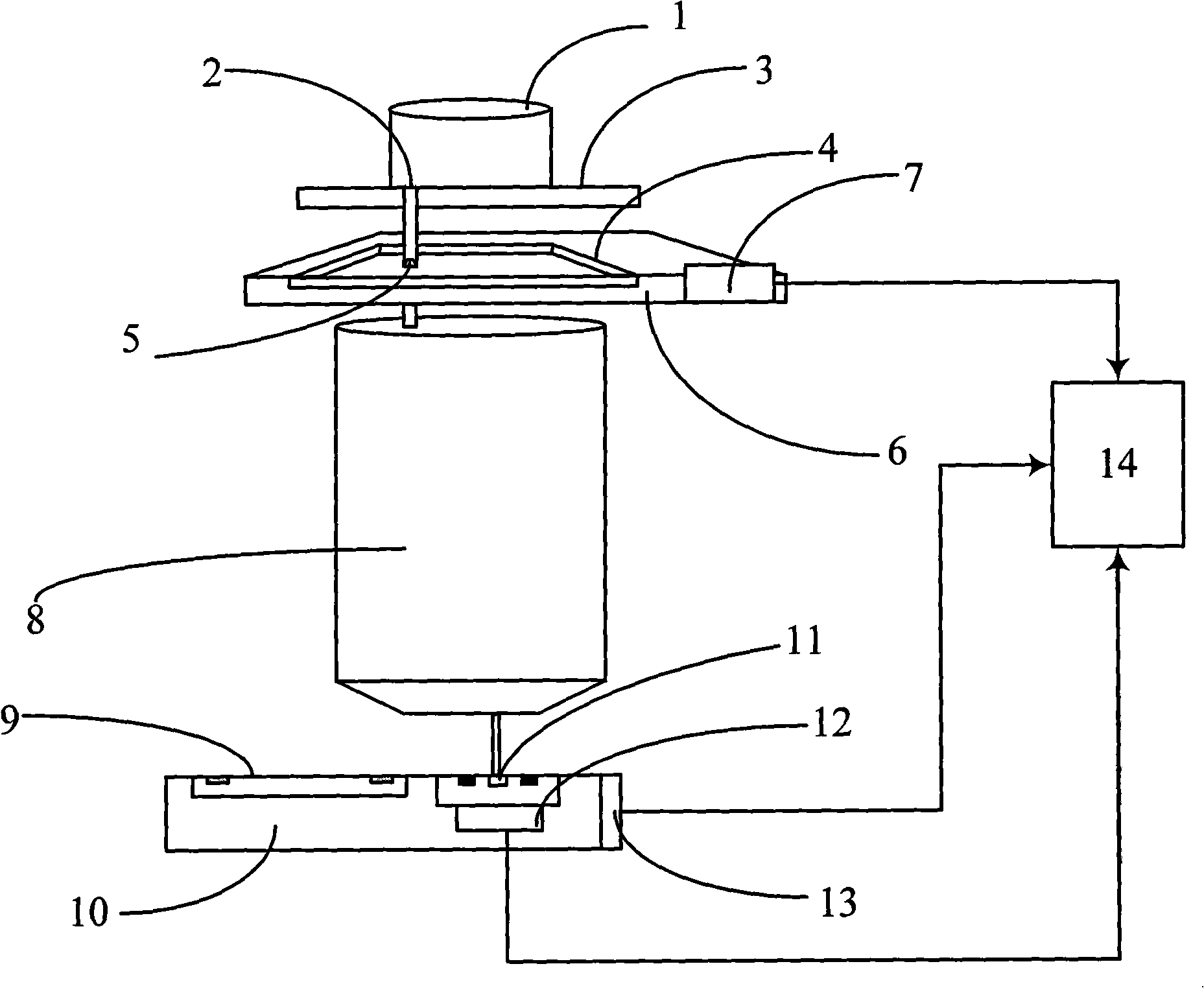

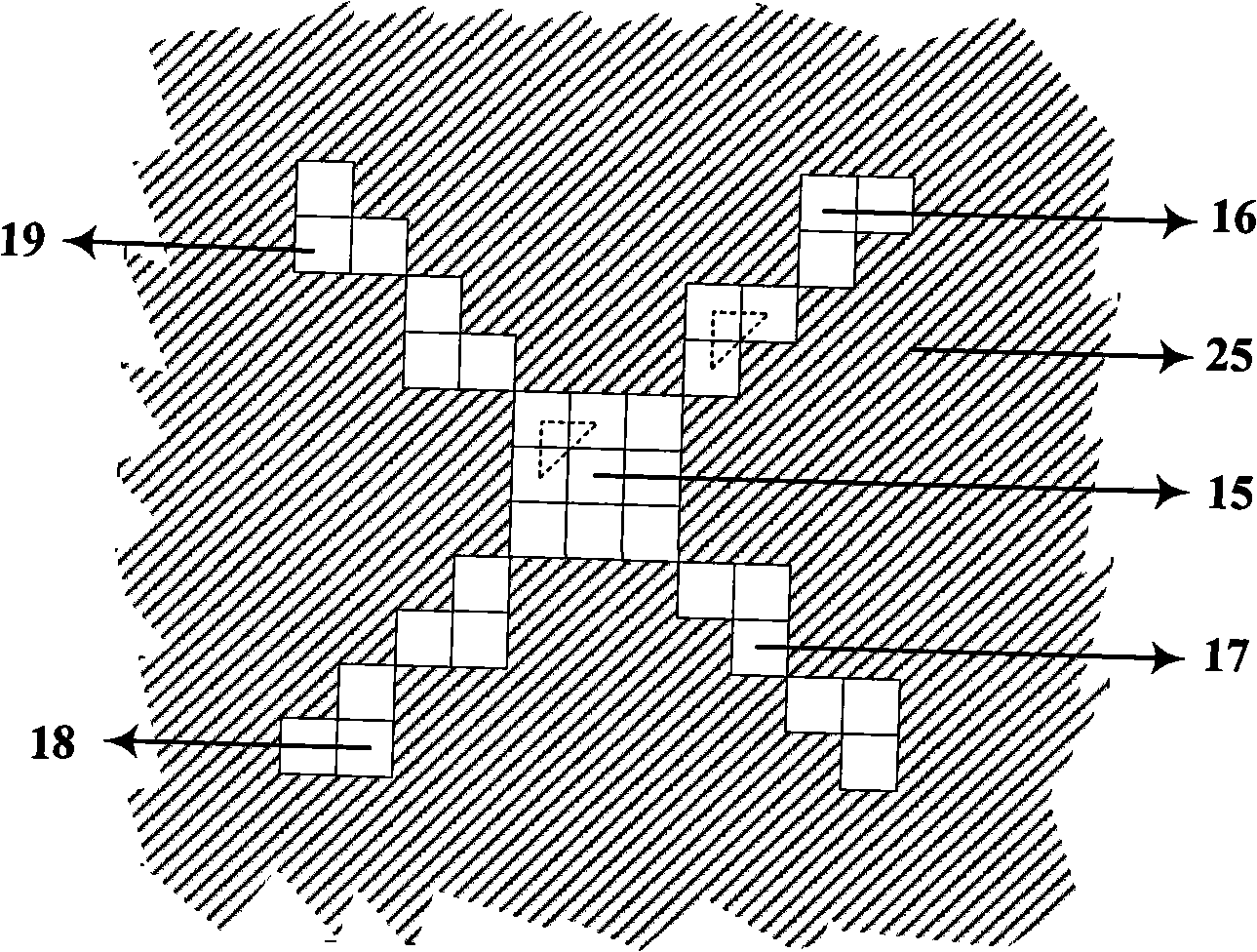

[0033] figure 1 It is a structural schematic diagram of an alignment system of a lithography apparatus applying the combination of two-dimensional coded normalized alignment marks and its alignment signal processing method of the present invention. The alignment system includes: a target patterning component 4 with patterning graphics (including Exposure composition graphics and alignment composition graphics 5); detection patterning component 9, which has a detection composition component mark 11, and a radiation spatial pattern detection device 12 thereunder; target patterning component carrier platform 6 and its position measuring device 7; detection composition The component carrying table 10 and its position measuring device 13 ; the projection system 8 and the alignment signal proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com