A method for making film electrode of direct alcohol fuel battery

A fuel cell membrane and electrode technology, which is applied to fuel cell parts, fuel cells, battery electrodes, etc., can solve the problems that the power density cannot reach the practical level and the battery life needs to be further improved, so as to improve the catalytic efficiency and The utilization rate of the catalyst, the effect of improving the performance and its stability, and improving the catalytic activity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

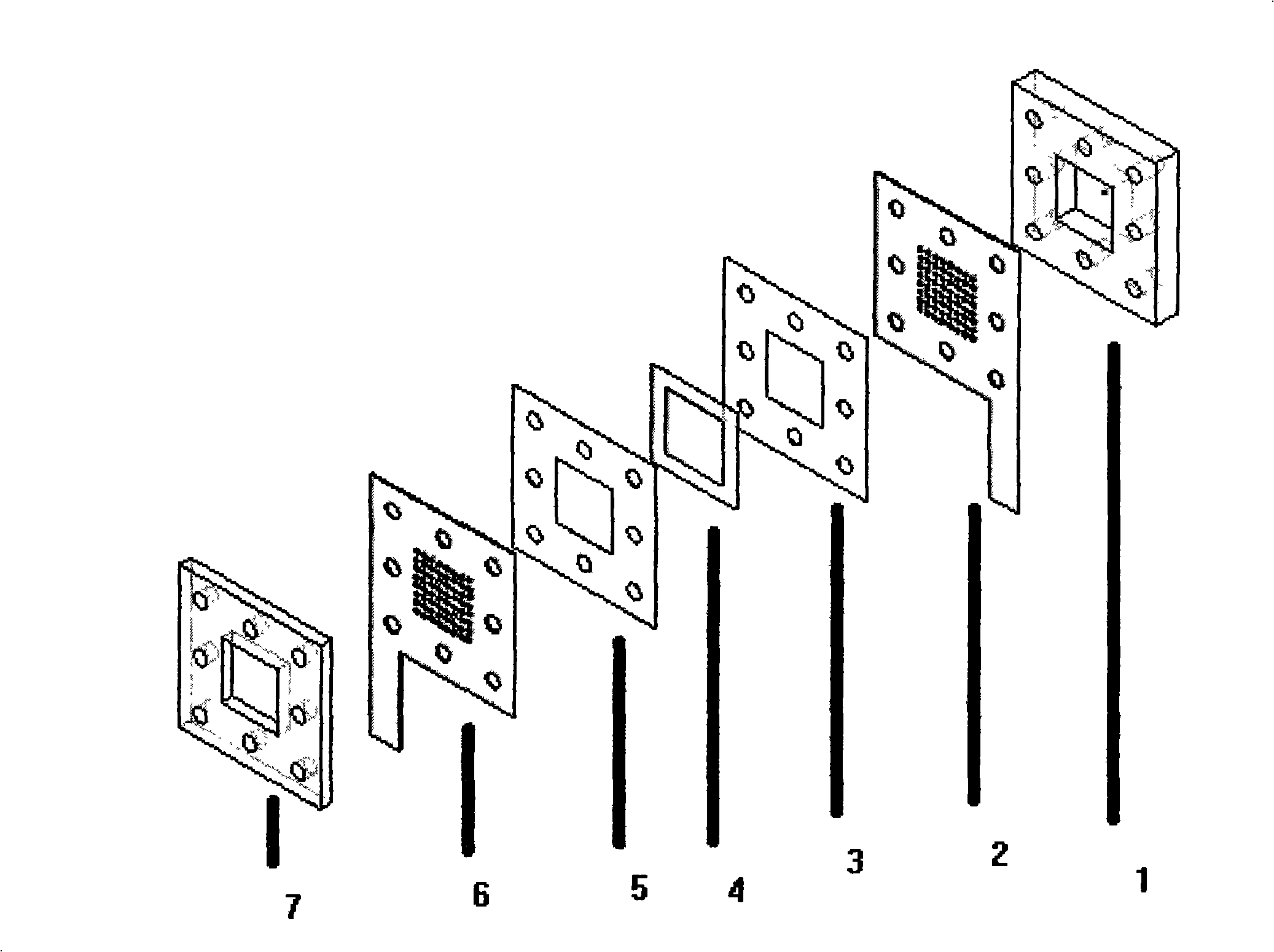

[0039] 1. Weigh 18mg of XC-72 carbon and 40mg of polytetrafluoroethylene emulsion with a mass ratio concentration of 12.4wt.%, and disperse in 1mL of isopropanol aqueous solution. The volume ratio of isopropanol and water is 1:1, and ultrasonically disperse 2h to get a uniform slurry.

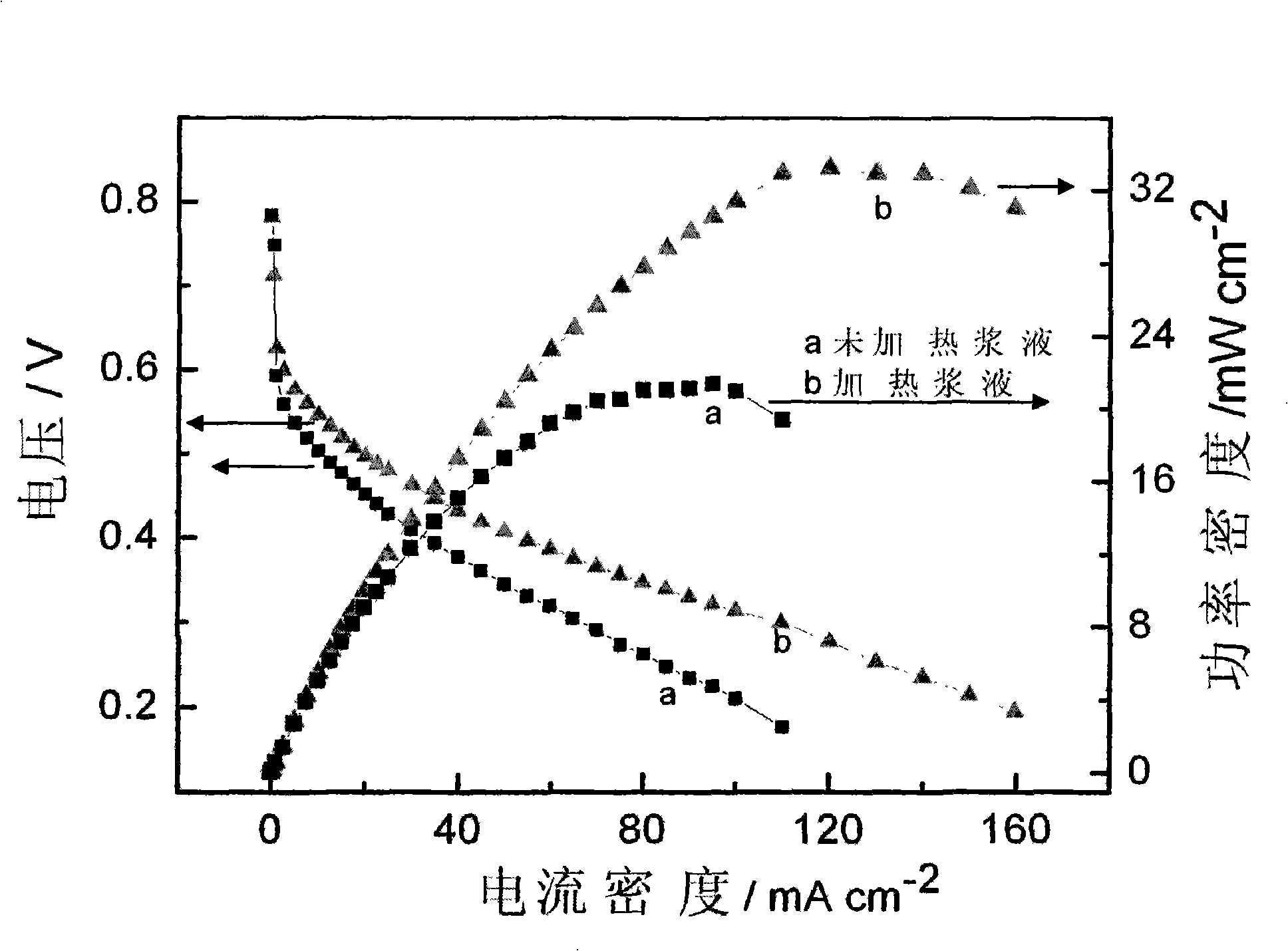

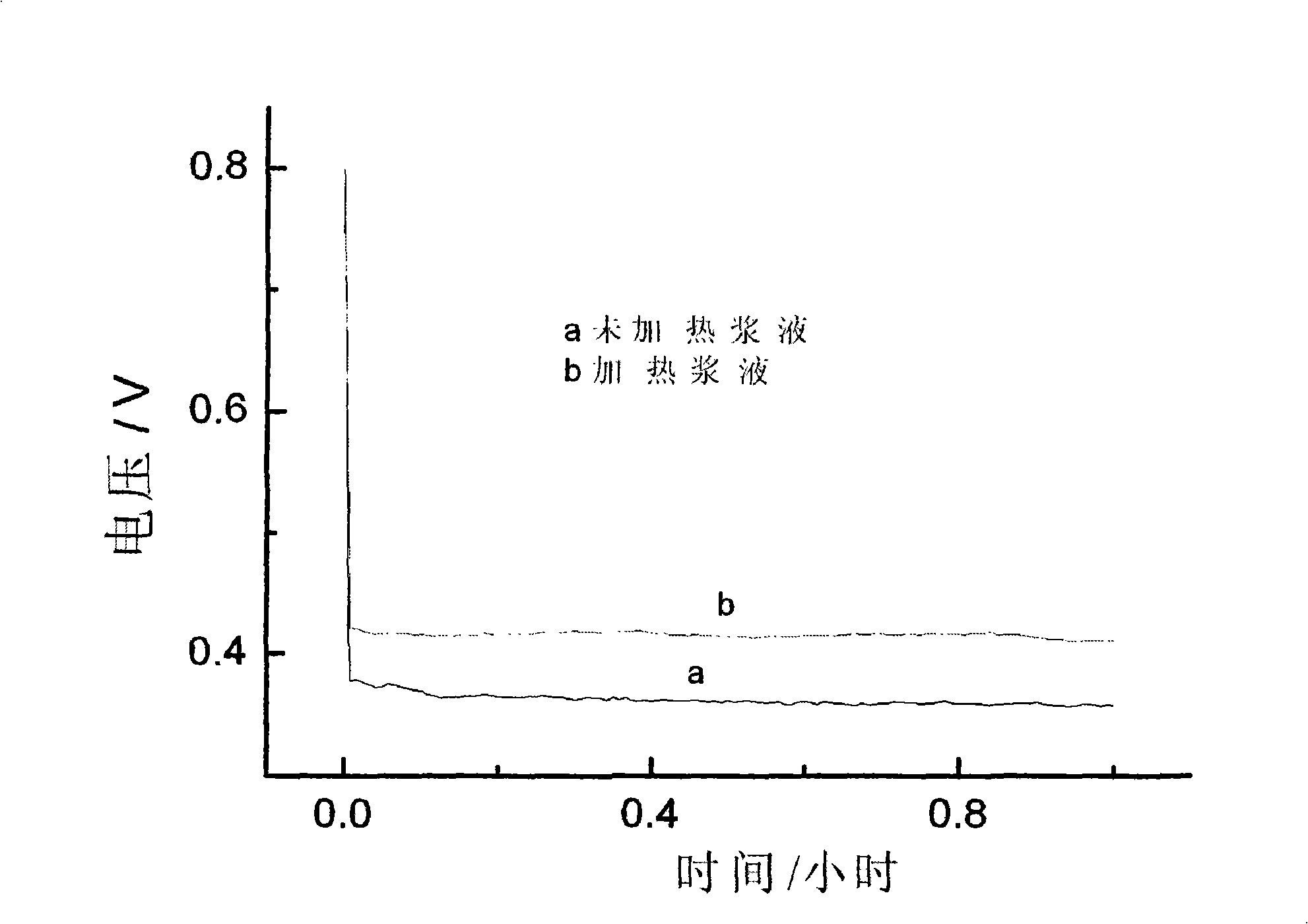

[0040] 2. Weigh 25 mg of platinum ruthenium black and place them in containers a and b, add 50 mg of ultrapure water to wet all the catalysts, add 85 mg of Nafion resin solution with a mass ratio concentration of 5.3 wt.%, and then add 2 mL of isopropyl A mixture of alcohol and water is used as a dispersant, the volume ratio of isopropanol and water is 1:1, the temperature is controlled at 80°C, and b is heated for 2 hours, and both a and b are ultrasonically dispersed for 2 hours.

[0041] 3. Take two sheets with an area of about 3×3cm 2 The carbon paper is used as the anode support layer, the carbon paper model is TGP-H-060, the hydrophobicity is 0wt.%, respectively marked as a, b, take a ...

Embodiment 2

[0046] 1. Weigh 16.1 mg of XC-72 carbon into the container, then add 40 mg of polytetrafluoroethylene emulsion with a mass ratio concentration of 12.4 wt.% and 1 ml of isopropanol as a binder and dispersant, isopropanol and The volume ratio of water is 1:1~3:1, and a uniform slurry can be obtained by ultrasonic dispersion for 3 hours.

[0047] 2. Weigh 80.3mg of Pt / C catalyst containing Pt60%, add 100ml of ultrapure water to wet all the catalyst, add 267.3mg of Nafion resin solution with a mass ratio concentration of 5.3wt.%, and then add 3mL of isopropanol and water The mixture of isopropanol and water was used as a dispersant, the volume ratio of isopropanol and water was 3:1, the temperature was controlled at 80°C for 1 hour, and ultrasonically dispersed for 3 hours.

[0048] 3. Take a sheet with an area of about 2×4cm 2 carbon paper, its model is TGP-H-060, and its hydrophobicity is 20wt.% as the supporting layer of the composite cathode. 2 In the region, the weight of...

Embodiment 3

[0054] 1. Weigh 16.1 mg of XC-72 carbon into the container, then add 40 mg of polytetrafluoroethylene emulsion with a mass ratio concentration of 12.4 wt.% and 1 ml of isopropanol as a binder and dispersant, isopropanol and The volume ratio of water is 1:1, and a uniform slurry can be obtained by ultrasonic dispersion for 3 hours.

[0055] 2 Weigh two 40.0mg Pt / C catalysts containing Pt60% and add them to containers a and b respectively, add 50ml ultrapure water to wet all the catalysts, then add 133.7mg Nafion resin with a mass ratio concentration of 5.3wt.% solution, and then add 3mL isopropanol aqueous solution as a dispersant, the volume ratio of isopropanol and water is 1:1, control the temperature at 30°C, and ultrasonically disperse for 3h. Take b and treat it in a 75°C water bath for 2h.

[0056] 3Take two sheets with an area of about 2×2cm 2 Carbon paper, whose model is TGP-H-060, with a hydrophobicity of 20wt.%, is used as the supporting layer of the composite ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com