Polypropelene composition capable of making with laser and preparation method thereof

A polypropylene composition and laser marking technology, which is applied in the field of polypropylene composition and its preparation, can solve the problems of material physical property degradation, difficulty in laser marking of polypropylene, excessive addition amount, etc., and achieve good surface regularity and marking Clear and fine contour lines, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

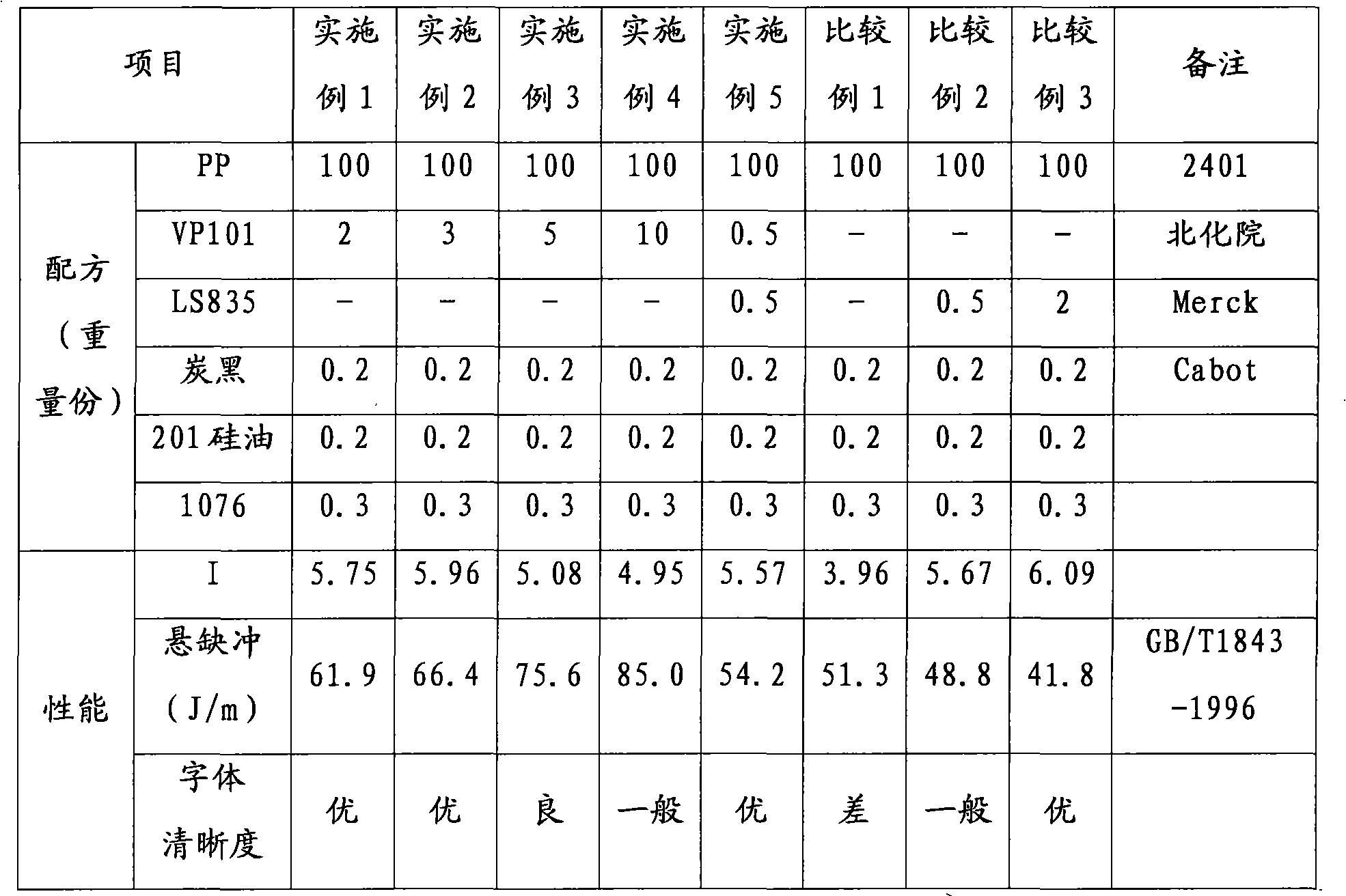

[0043] Polypropylene resin (PP, brand 2401, Sinopec Yanshan Branch) and simethicone oil (brand 201, viscosity is 1000 centipoise, Beijing Chemical Industry No. 2 Plant) are measured and placed in a high-speed mixer for processing; Polypropylene, superfine fully vulcanized powdered styrene-butadiene rubber (brand VP101, Sinopec Beijing Research Institute of Chemical Industry, particle size 80nm, gel content 90%), carbon black (Germany, Cabot, M470), antioxidant 1076 ( Beijing No. 3 Chemical Factory) after stirring evenly, put the mixture into a twin-screw extruder (Germany, WP company, model ZSK-25) for melt blending and extrusion and granulation. The extrusion temperature is 180-200 °C. Speed 300rpm. Dry the particles obtained through the extruder at 90°C for 6 hours, and then inject them into standard strips under the condition of 170-225°C for laser marking tests and related performance tests. The specific formula is shown in Table 1, wherein the contents of each componen...

Embodiment 5

[0045] Polypropylene resin (PP, brand 2401, Sinopec Yanshan Branch) and simethicone oil (brand 201, viscosity is 1000 centipoise, Beijing Chemical Industry No. 2 Plant) are measured and placed in a high-speed mixer for processing; Polypropylene, superfine fully vulcanized powdered styrene-butadiene rubber (brand VP101, Sinopec Beijing Research Institute of Chemical Industry, particle size 80nm, gel content 90%), carbon black (Germany, Cabot, M470), laser additives (brand LS835, German Merck), antioxidant 1076 (Beijing Chemical Industry No. Granules, all the other steps and conditions are the same as in previous examples 1-4. The specific formula is shown in Table 1, wherein the contents of each component are in parts by weight. The performance results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com