Non-welding flange-connection stainless steel metal flexible pipe and production method

A metal hose and stainless steel technology, applied in the direction of hoses, hose connection devices, pipes/pipe joints/fittings, etc., can solve problems such as leakage, non-metallic hose scalding, easy cracking of welding joints, etc., to achieve Simple on-site piping, improved work efficiency, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A non-welded stainless steel metal hose and its manufacturing method of the present invention will be described in detail below in conjunction with the embodiments.

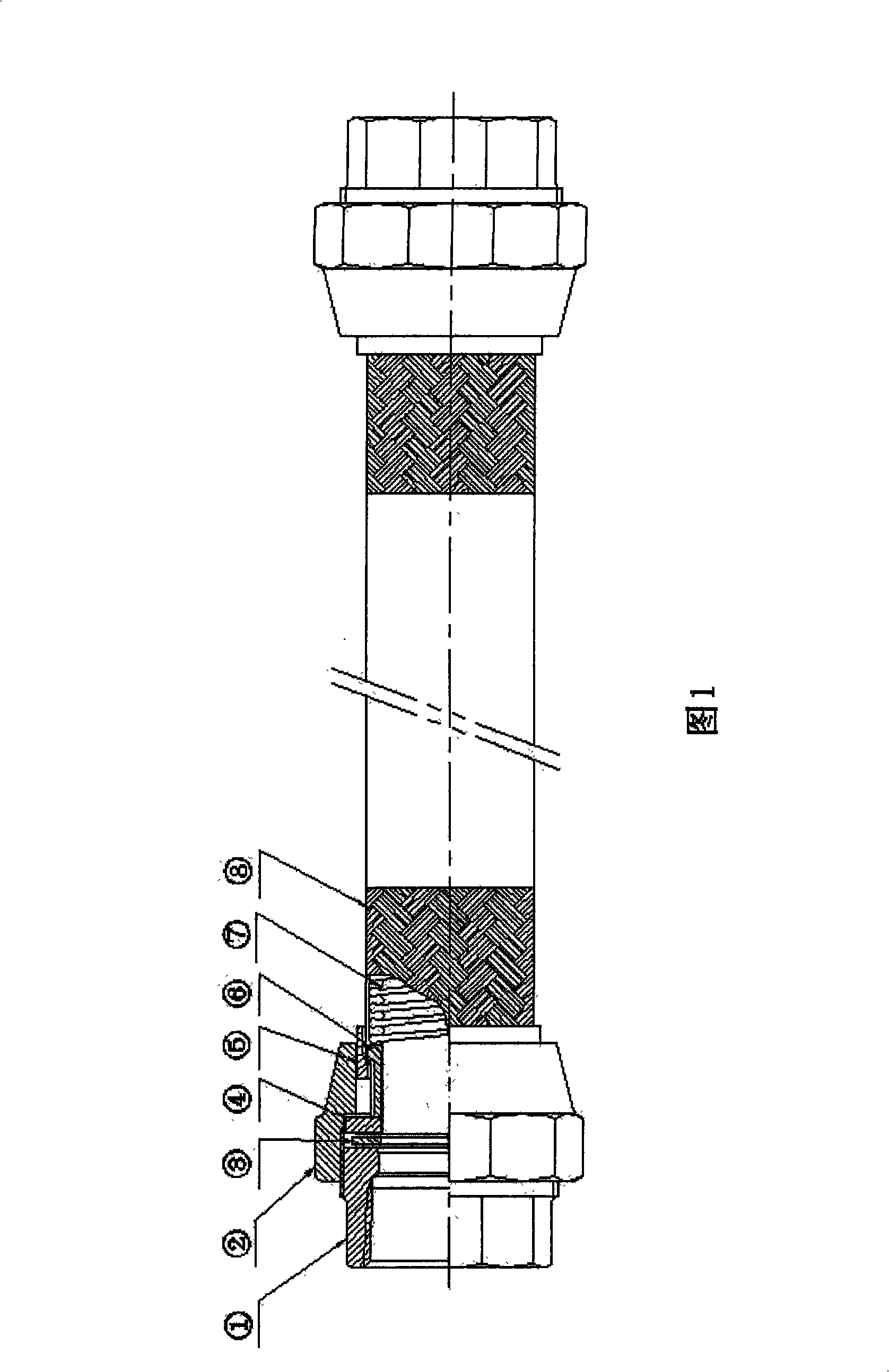

[0029] The structure of the non-welded stainless steel metal hose of the present invention is illustrated below with examples, please refer to the attached drawings: Fig. 1 is an explanatory diagram of the main parts of the non-welded stainless steel metal hose of Example 1, the non-welded stainless steel hose of Example 1 The metal bellows 7 is composed of a helical or Ω corrugated section in which crests and troughs are alternately formed. There are straight pipe sections at both ends of the corrugated section. The cylindrical stainless steel soft metal mesh 8 woven by metal wires and its outer jacket can prevent the stainless steel metal bellows from being elongated and deformed due to internal pressure; and protect the stainless steel metal bellows to a certain extent, the inner ring 6 sets At the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com