Testing apparatus of multi-layer nano-film tunneling micro-gyroscope

A detection device and nano-membrane technology, which is applied in the direction of measuring device, gyro effect for speed measurement, gyroscope/steering sensing equipment, etc., can solve problems such as difficult to meet, precision drift, effective capacitance area limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

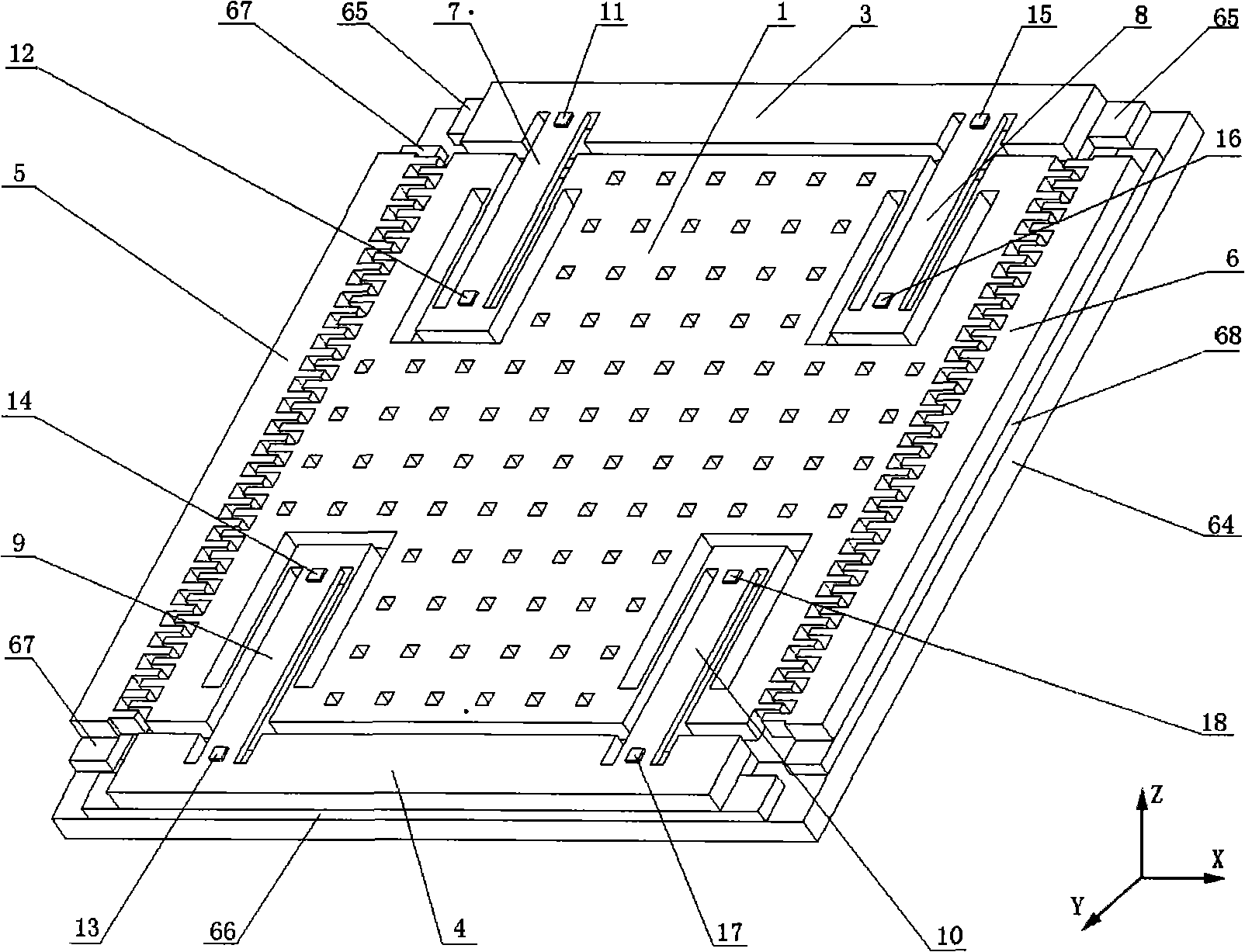

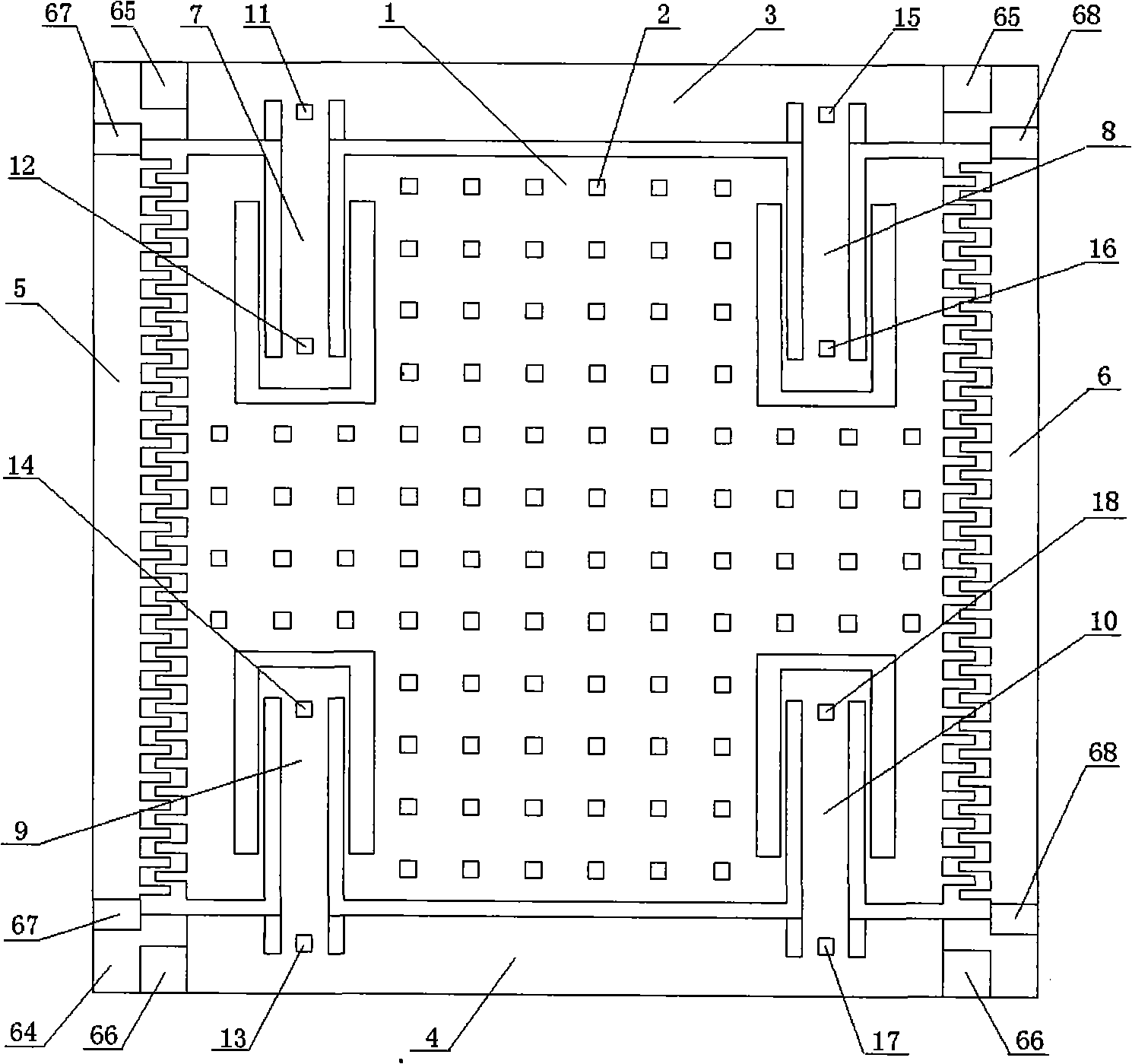

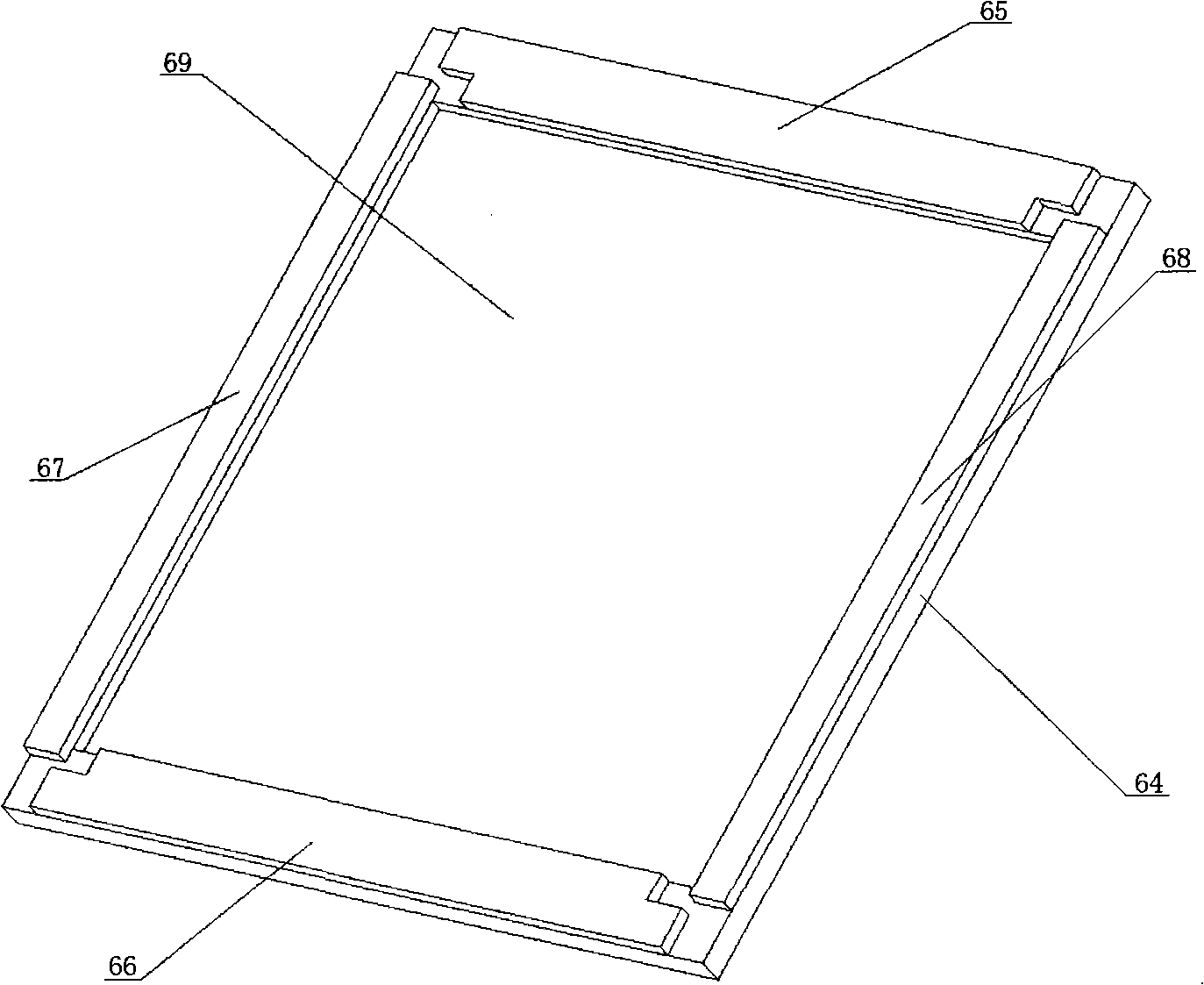

[0037] figure 1 , 2 As shown, it is an overall structure diagram, with a glass substrate 64 as a carrier, fixed electrode positive poles 65, 66, comb-tooth electrode negative poles 67, 68 are arranged on the front, rear, left and right parts, and the bottom groove 69 is in the middle. Inside 69 is the sensitive mass 1, with the sensitive mass 1 as the center, fixed comb teeth 5, 6 are arranged on the left and right, and are cross-connected with the comb teeth 19, 20 on the sensitive mass 1, and the front and rear fixed seats 3, 4 are connected with the The detection mechanisms 7, 8, 9, 10 are anastomosingly connected, and the damping holes 2 are 96 through-hole squares, which can also be designed as a circle or a rectangle as required, or 48, 72, or 120 can be set as required. It can be determined according to the application environment and damping coefficient.

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com