Shaft sleeve structure of vehicle speed mileage sensor

A sensor and bushing technology, which is applied in the manufacturing field of automotive electronic components, can solve the problems of different machining accuracy, difficult to determine assembly tolerances, and wear of rotating shafts and bushings, so as to achieve ultra-low friction coefficient, convenient assembly and processing, The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

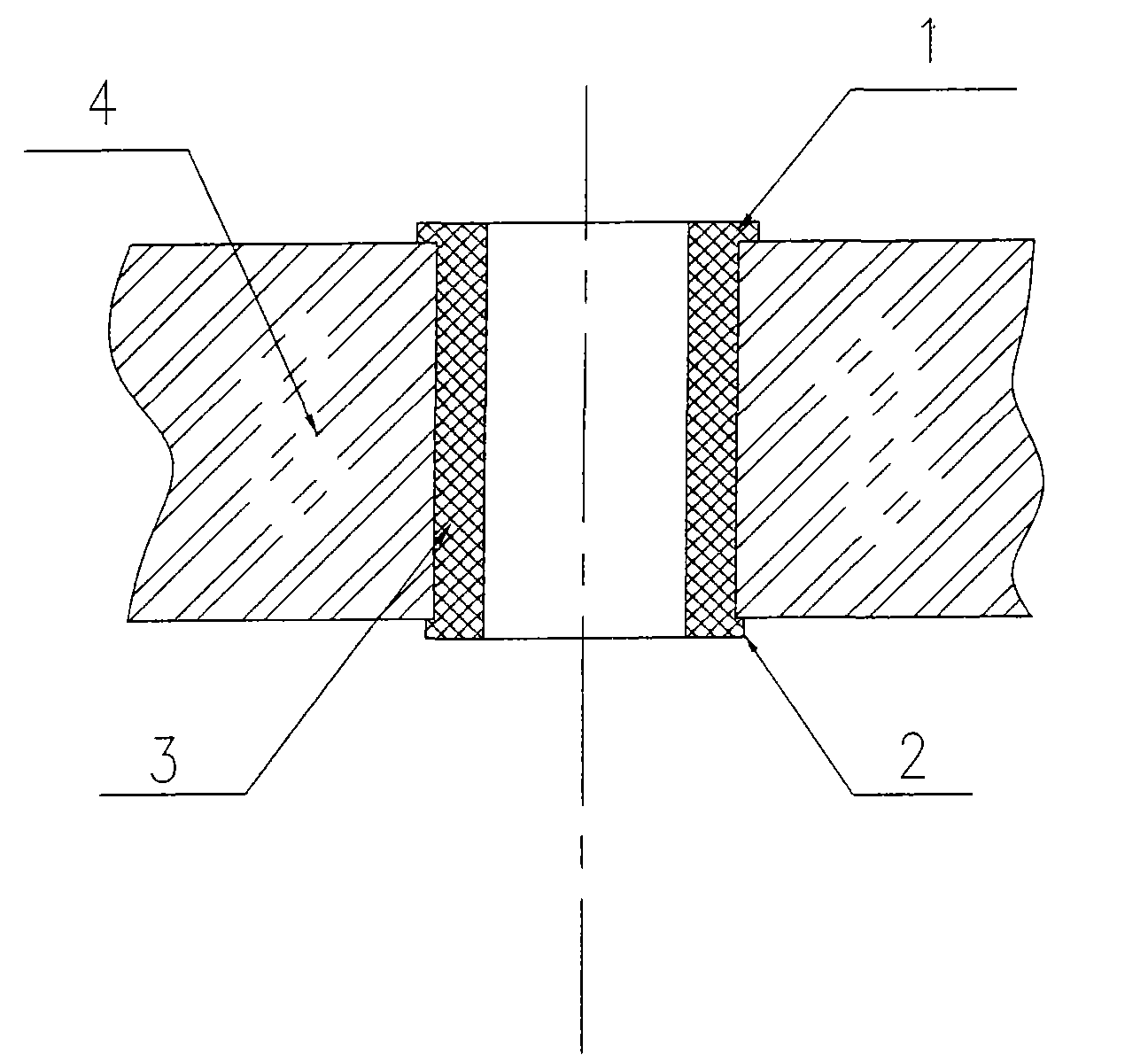

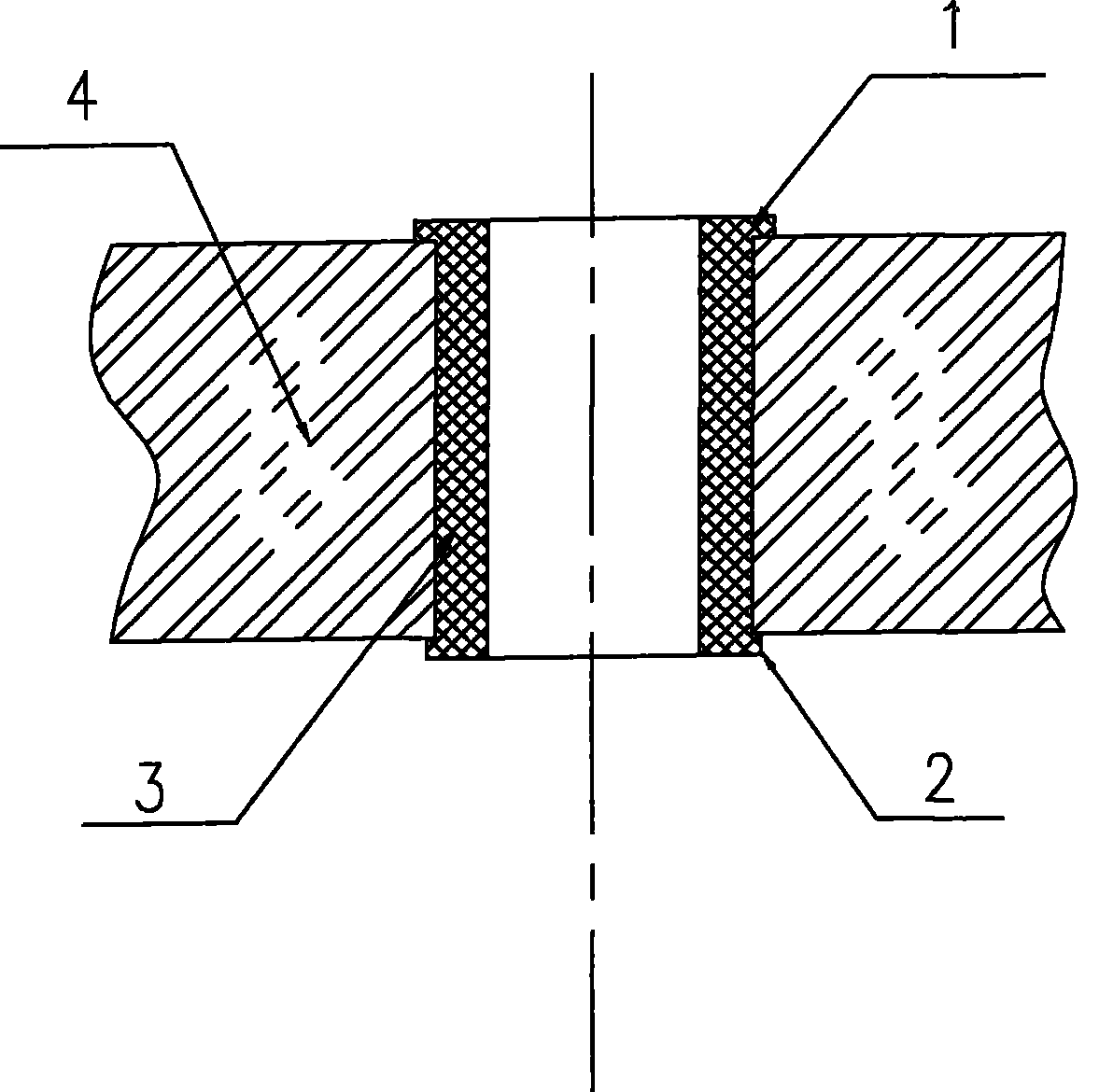

[0008] The present invention is mainly composed of a sensor aluminum shell 4, a shaft sleeve 3 placed in the sensor aluminum shell 4, etc., the material of the shaft sleeve 3 is plastic, preferably polyvinylidene fluoride plastic, and the upper part of the shaft sleeve 3 is provided with a convex edge 1 , the exposed part after the lower part is embedded in the sensor aluminum shell 4 is the extruded flanging structure 2 .

[0009] When used on the vehicle speed mileage sensor, the raw material is injection-molded into a shaft sleeve 3 of the required size, and the shaft sleeve 3 is pressed into the shaft hole of the sensor aluminum shell 4 with a press, and then reamed out with a reamer to match the diameter of the shaft. The hole diameter can be assembled with a rotating shaft. The invention is also applicable to all shaft sleeves with small force on the rotating grinding surface, light weight of the rotating parts and suitable temperature range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com