Small-caliber steel pipe lateral impact sample flattening method

A transverse impact and small-diameter technology, applied in the preparation of test samples, measuring devices, instruments, etc., can solve problems such as low rigidity, reduced production efficiency, and indentation on the inner surface of pipes, so as to achieve simple processing technology and improve production efficiency , the effect of low material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Example 1. The specification of a certain pipe product is Φ71.17×8mm. Now it is necessary to test its transverse impact energy. Sample preparation can be carried out according to the following steps:

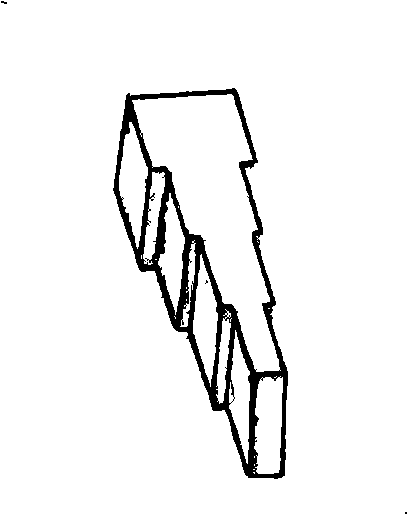

[0036] (1) Saw a tube material with an arc length of about 70mm and an axial length of about 50mm on the sample tube to be tested, such as Figure 6 shown.

[0037] (2) Combine No. 1 mold block and No. 2 mold block together, that is, No. 1 mold block is placed on No. 2 mold block, and then put Figure 7 The block in the block is placed on the No. 1 mold block, and the center line is aligned, such as Figure 7 shown.

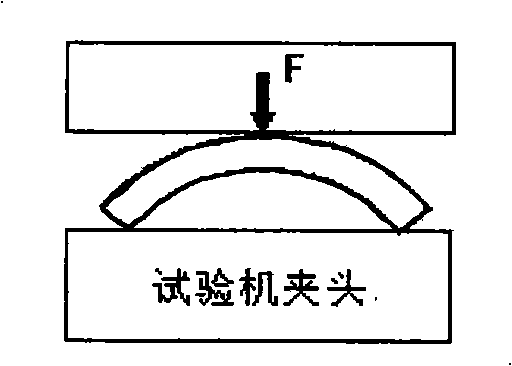

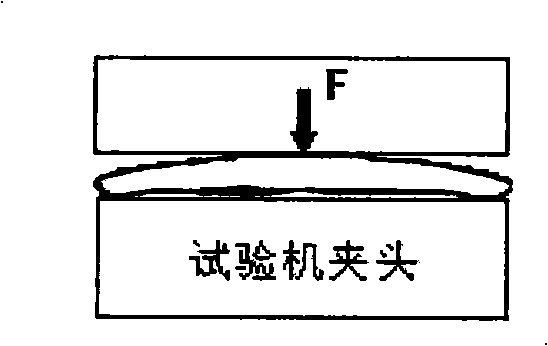

[0038] (3) Will Figure 7 The components shown are placed together on the pressure flattening device, loaded until a flat part appears on the upper part of the sample to be tested, and unloaded to replace the mold assembly to the No. 2 mold block and No. 3 mold block, such as Figure 8 shown.

[0039] (4) Repeat steps (2) and (3) until the sample to be ...

example 2

[0041] Example 2, the specification of a pipe product is Φ88.90×9.53mm, and now it is necessary to test its transverse impact energy, and the sample preparation can be carried out according to the following steps:

[0042] (1) Same as Example 1, saw the pipe material with an arc length of about 70mm and an axial length of about 50mm on the sample pipe to be tested, such as Figure 6 shown.

[0043] (2) Due to the large inner diameter of the pipe of this specification, the difference from Example 1 is that the No. 2 mold block and the No. 3 mold block can be directly combined at the beginning, and the No. 2 mold block is placed on the No. 3 mold block, and then Will Figure 9 The material shown is placed on the No. 2 mold block, and the center line is aligned, as shown in Figure 10.

[0044] (3) Will Figure 10 The components shown are placed together on the pressure flattening device, loaded until a flat part appears on the upper part of the sample to be tested, and unloaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com