Fluid closed loop type on-line liquid density transmitter

A liquid density, closed-loop technology, applied in the direction of determining the specific gravity by measuring the pressure difference, which can solve the problems of data deviation, large workload, and inability to obtain data curves, achieve smooth output value curves, avoid accidental errors, installation and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

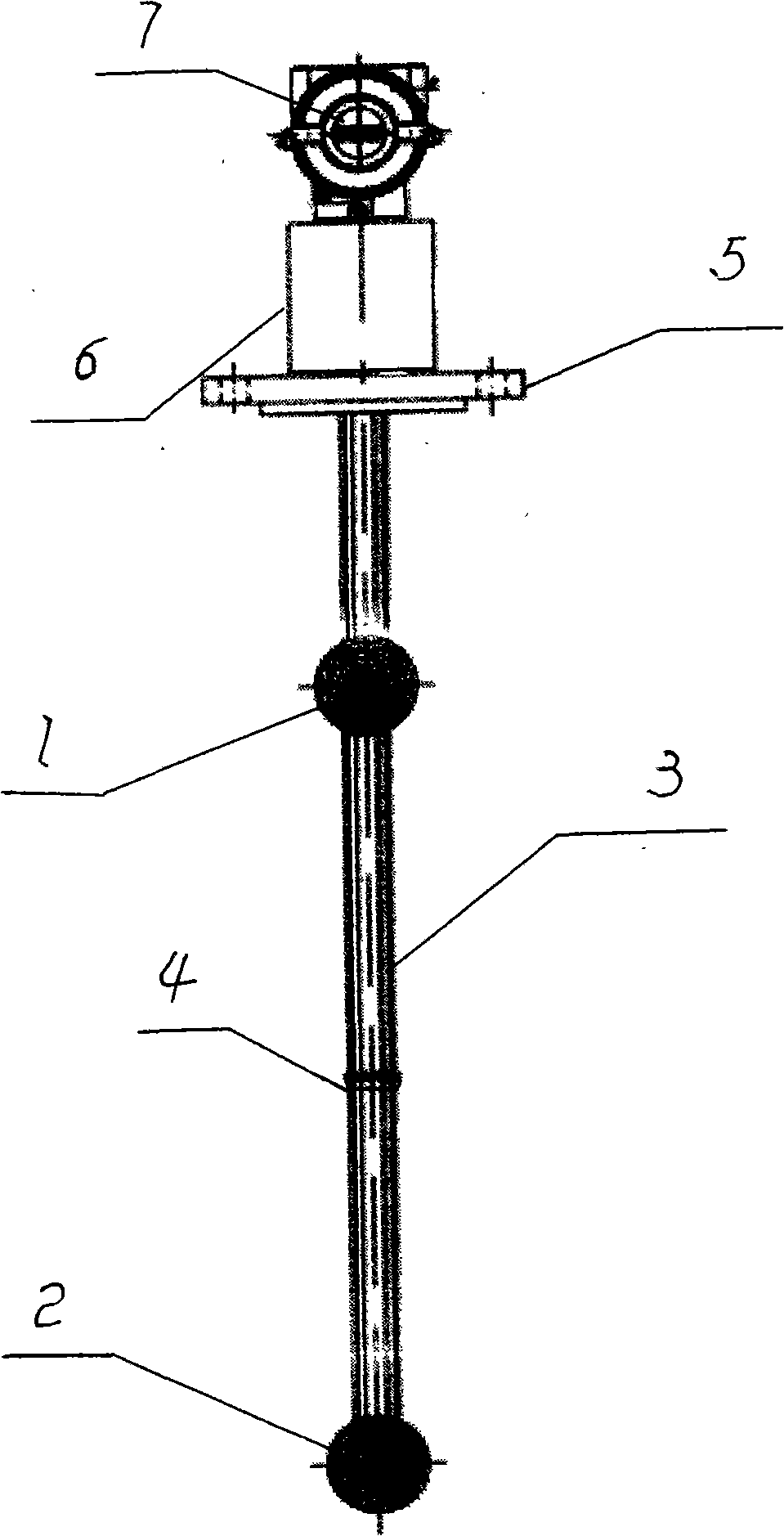

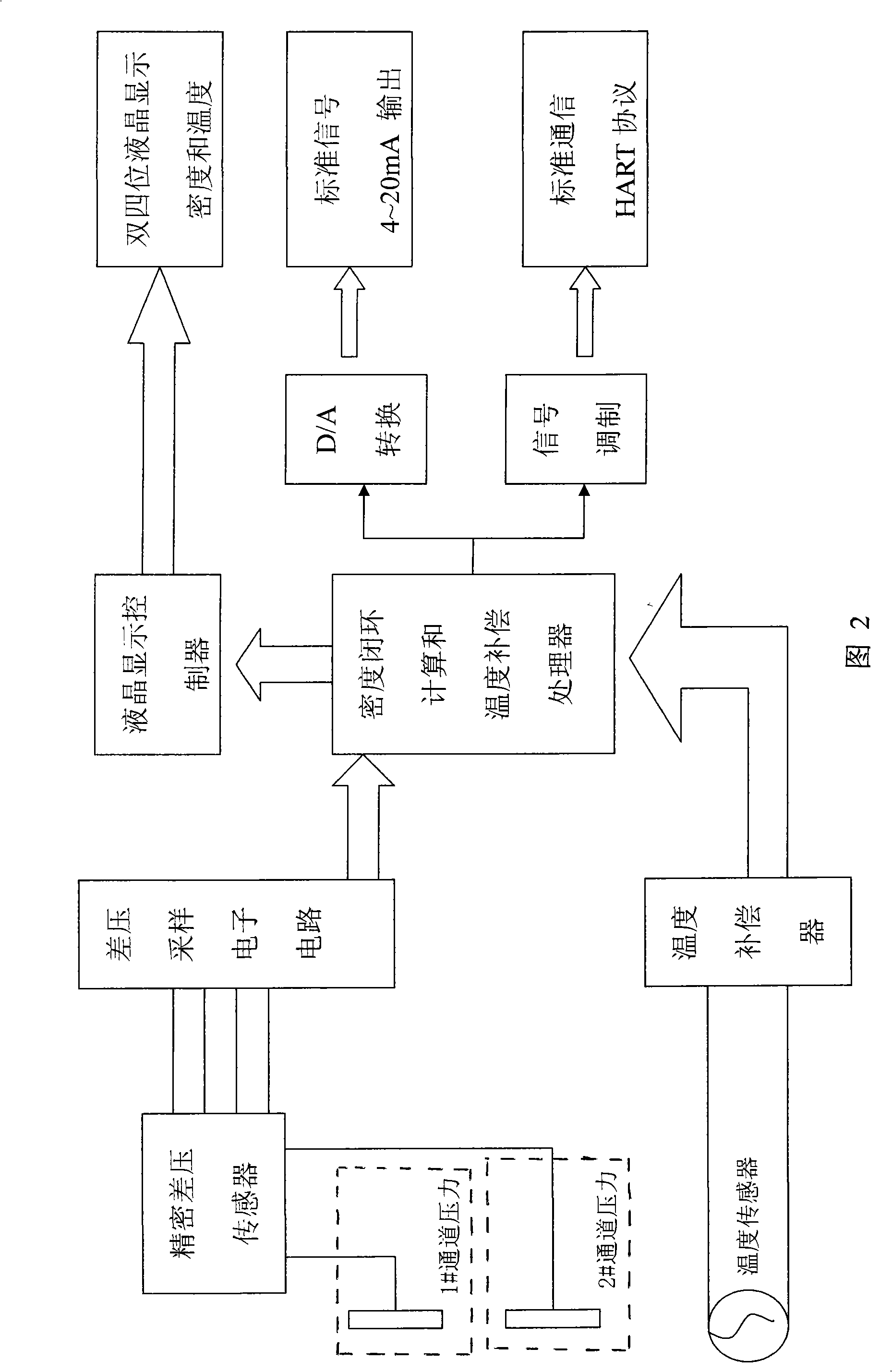

[0024] Such as figure 1 Shown in -2: Fluid closed-loop integrated online liquid density test transmitter, mainly composed of a density probe and an output display communication meter, which is characterized in that: a precision differential pressure sensor and a temperature sensor are arranged on the density probe, and the meter head On it, temperature compensator, density closed-loop calculation and temperature compensation processor, liquid crystal display control system, real-time data display device and interface for power supply to the transmitter, the precision differential pressure sensor on the density probe is connected to the differential pressure sampling electronic circuit , the output signal of the differential pressure sampling electronic circuit is sent to the density closed-loop calculation and temperature compensation processor, the display signal of the density closed-loop calculation and temperature compensation processor is sent to the display through the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com