Foodstuff processing

A food, unprocessed technology, applied in the field of processed food, can solve the problems of discarding and short storage time, achieve the effect of less oil absorption, improve frying conditions, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

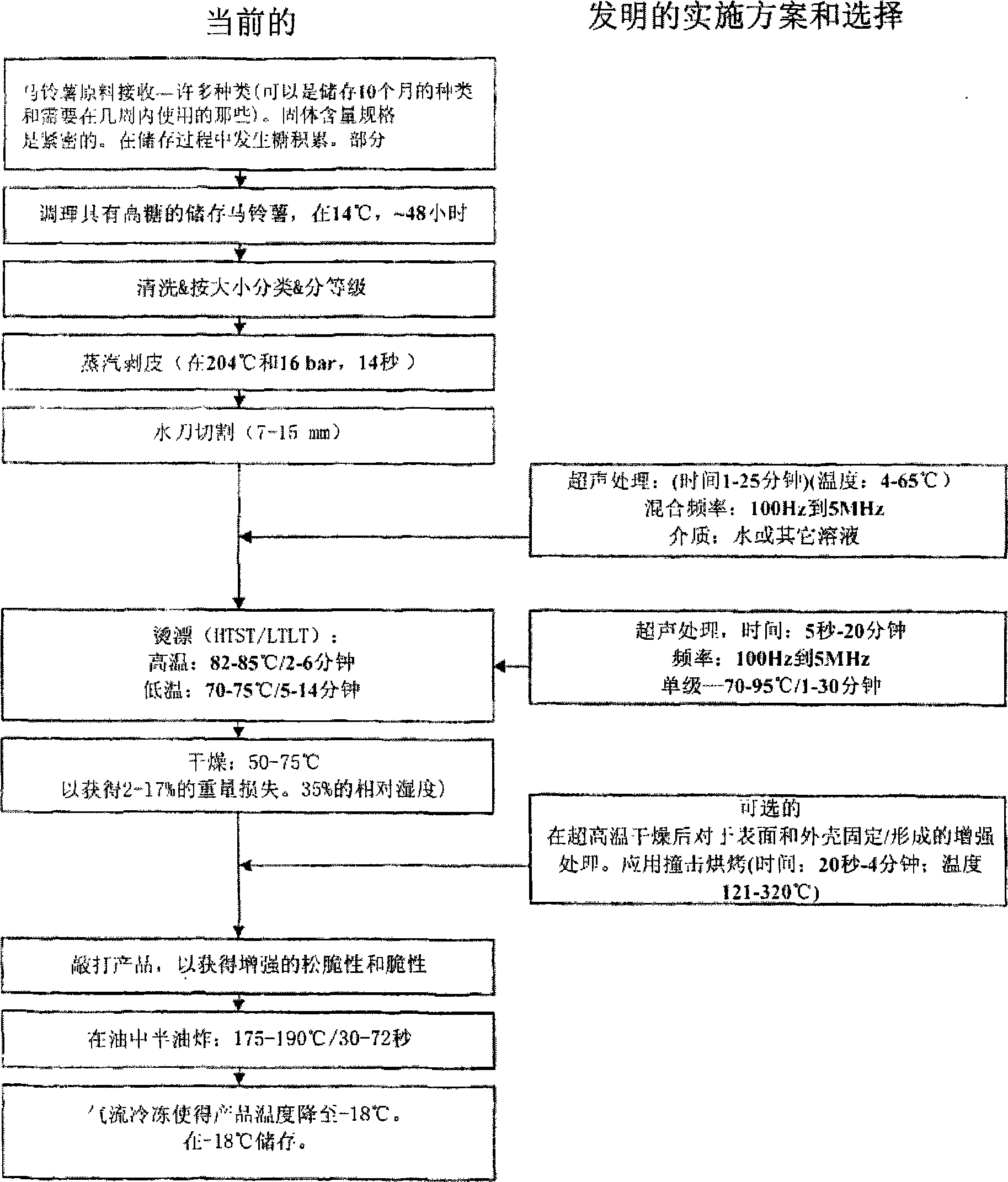

[0065] For the first embodiment, after waterjet cutting, ultrasonic processing of the strips is performed at 4°C to 70°C for 1 to 25 minutes using a mixing frequency in the range of 100 Hz to 5 MHz, the potato strips being in water or in another medium.

[0066] For the second embodiment, in the alternative or in addition, the sonication is a blanching step at 65-95° C. for 5 seconds to 30 minutes using a mixing frequency in the range of 100 Hz to 5 MHz.

[0067] For the third embodiment, an optional further step of irradiation and / or microwave heating at 120-350° C. for 20 seconds to 4 minutes is additionally applied after the drying step to enhance drying, surface fixation and crust formation .

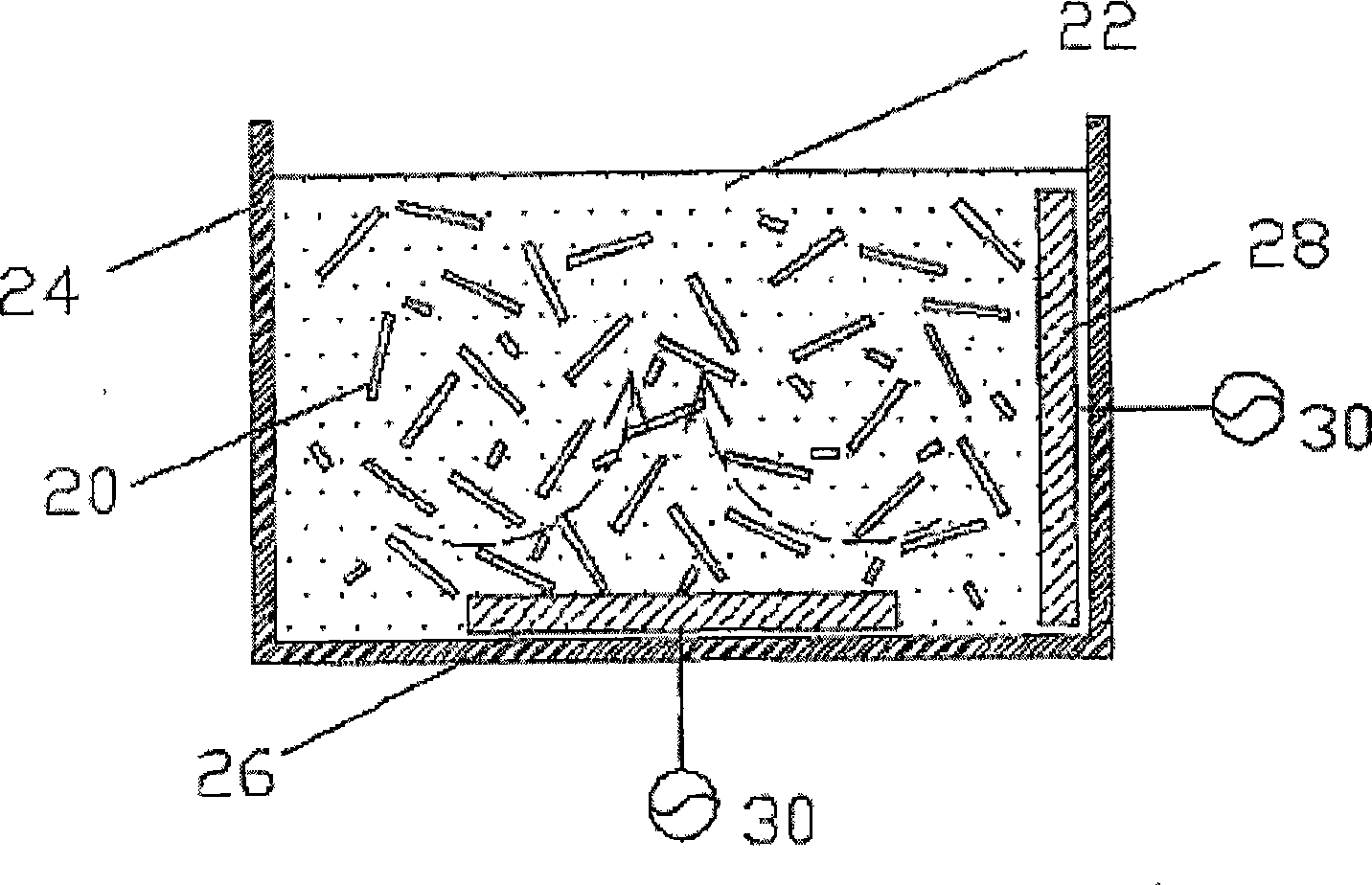

[0068] figure 2 One embodiment of the present invention schematically illustrates a step in the overall French fry production process in which cut potato strips or slices 20 are advanced through vessel 22 in vessel 24 containing water as the transfer medium. Ultrasonic transduce...

Embodiment 1

[0085]Raw potatoes of the Russet Burbank variety were washed, peeled and cut into strips having a square cross-sectional shape 10 mm wide. The strips were immersed in a water bath at 25°C and subjected to an ultrasonic field for 2 minutes using transducers operating at 40 kHz and 1 MHz, respectively.

[0086] The strips were then blanched in a two-step process comprising 4 minutes at 82.5°C and 10 minutes at 70°C.

[0087] The bars were then conventionally dried at 65°C and 40% relative humidity to achieve a weight loss of 10-12%.

[0088] Subsequently, the dried strips were semi-fried at 190°C for 50 seconds and then frozen at -18°C.

Embodiment 2

[0090] The method of Example 1 was repeated, except that the sonication was modified to 12 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com