Wastewater treatment device for chrome plating by coke-scrap iron method

A wastewater treatment and iron filings technology, which is applied in metallurgical wastewater treatment, reduced water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of polluting drinking water and industrial water, endangering agriculture, forestry, animal husbandry and fishery, and affecting industry and agriculture Problems such as normal production, to achieve the effect of ensuring effective precipitation, ensuring continuity, and benefiting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

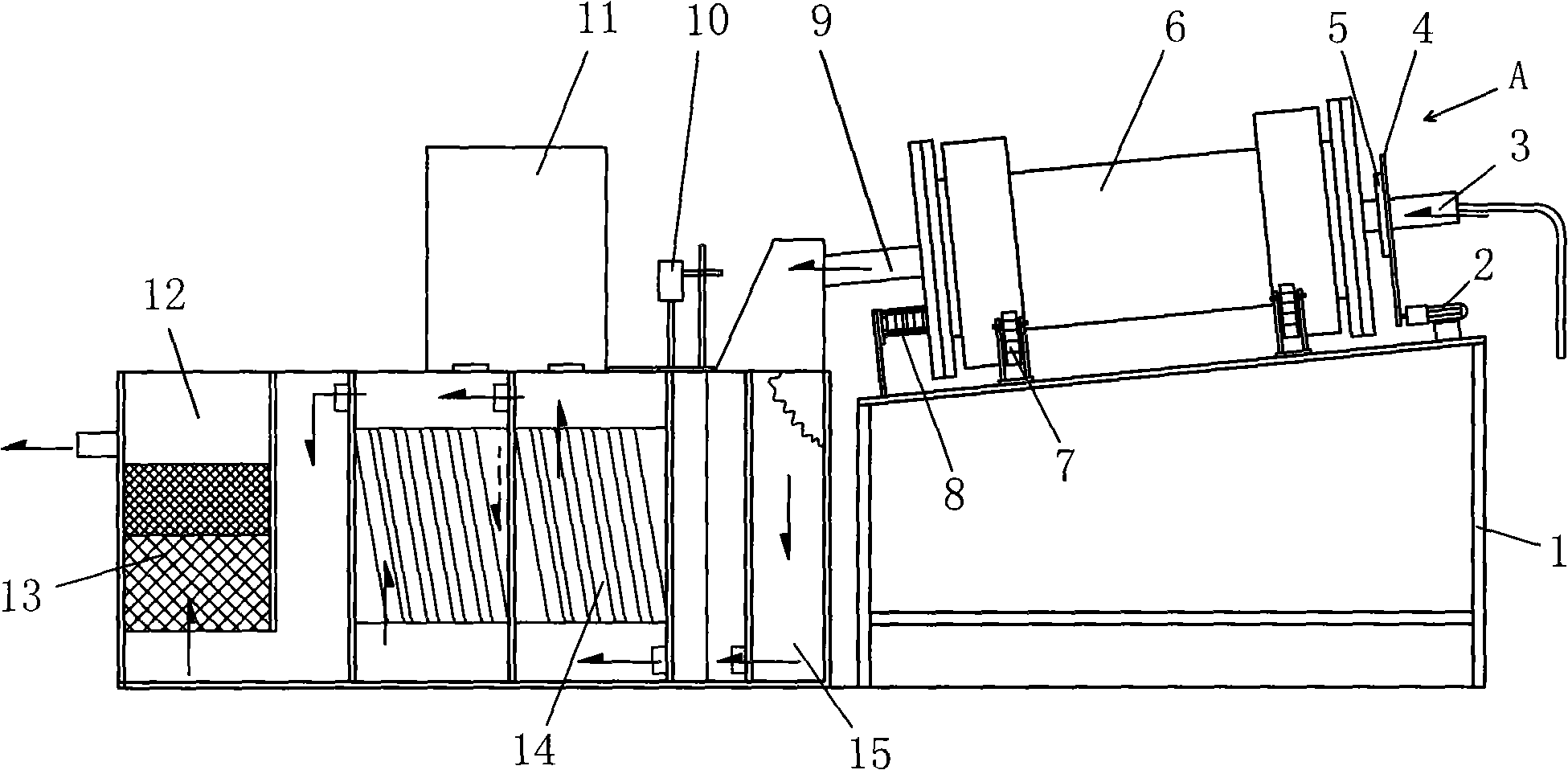

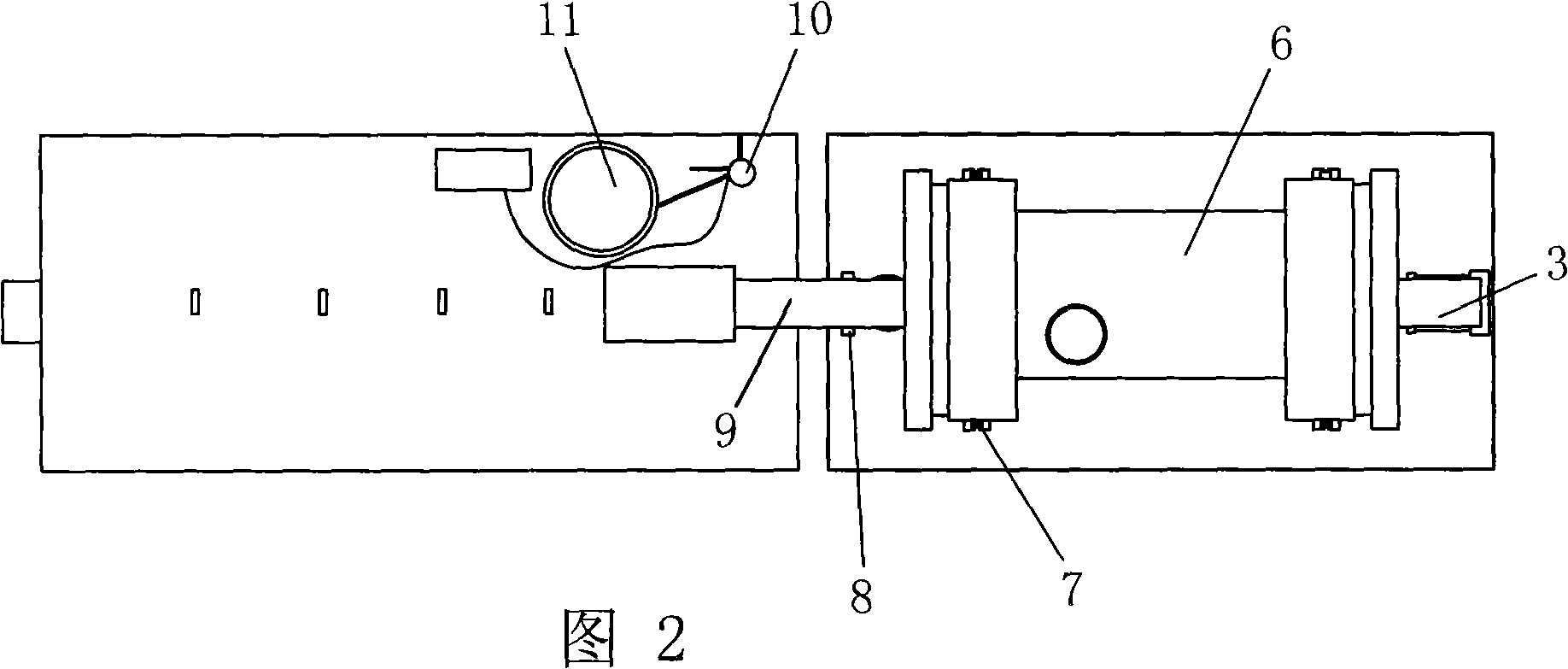

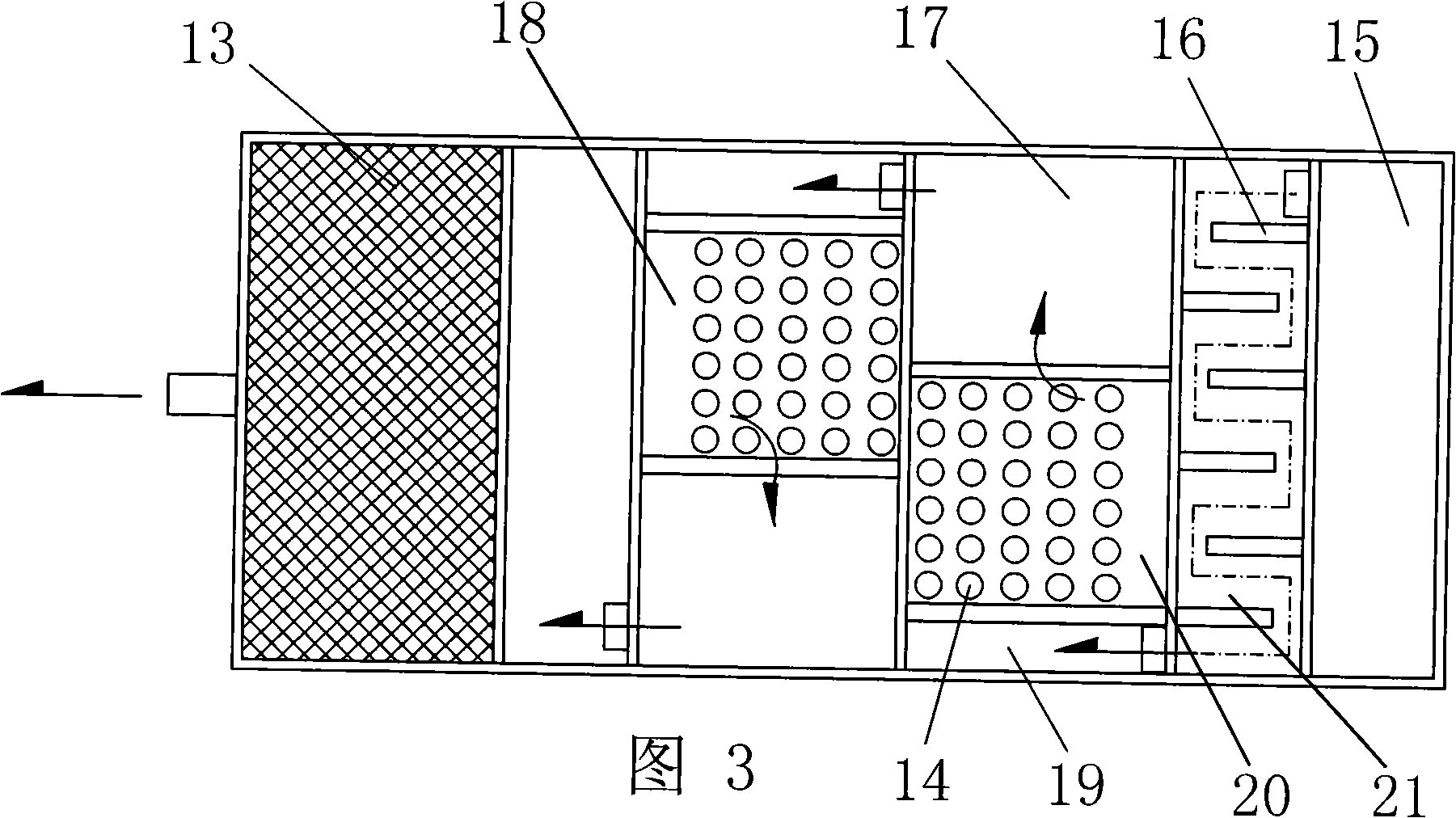

[0032] Below in conjunction with embodiment and Figure 1 to Figure 4 The present invention is further described.

[0033] The coke-iron scrap method chrome-plating waste water treatment equipment provided by the invention comprises following reaction unit and aftertreatment unit:

[0034] Reaction device: mainly composed of a drum 6, a stirrer 10, a medicine tank 11 and a plurality of curved plates 16. The drum 6 is movably supported on the frame 1, and is tilted toward the sedimentation tank; the two ends of the drum are respectively provided with a water inlet 3 and a water outlet 9, and the water inlet 3 is connected with the water source that requires chrome-plating waste water through the water inlet pipe, and the water outlet 9 is facing the first transition storehouse 15 below it. Agitator 10 and medicine tank 11 are located on the sedimentation water tank. A plurality of curved plates 16 are arranged in a tooth shape and fixed on the sides of the neutralization tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com