Novel composite vesicant

A technology of compound foaming agent and organic foaming agent, applied in the field of foaming agent, can solve the problems of difficult to improve production efficiency, reduce foaming efficiency, difficult to mix uniformly, etc., achieve low cost, improve product quality, and improve component composition. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

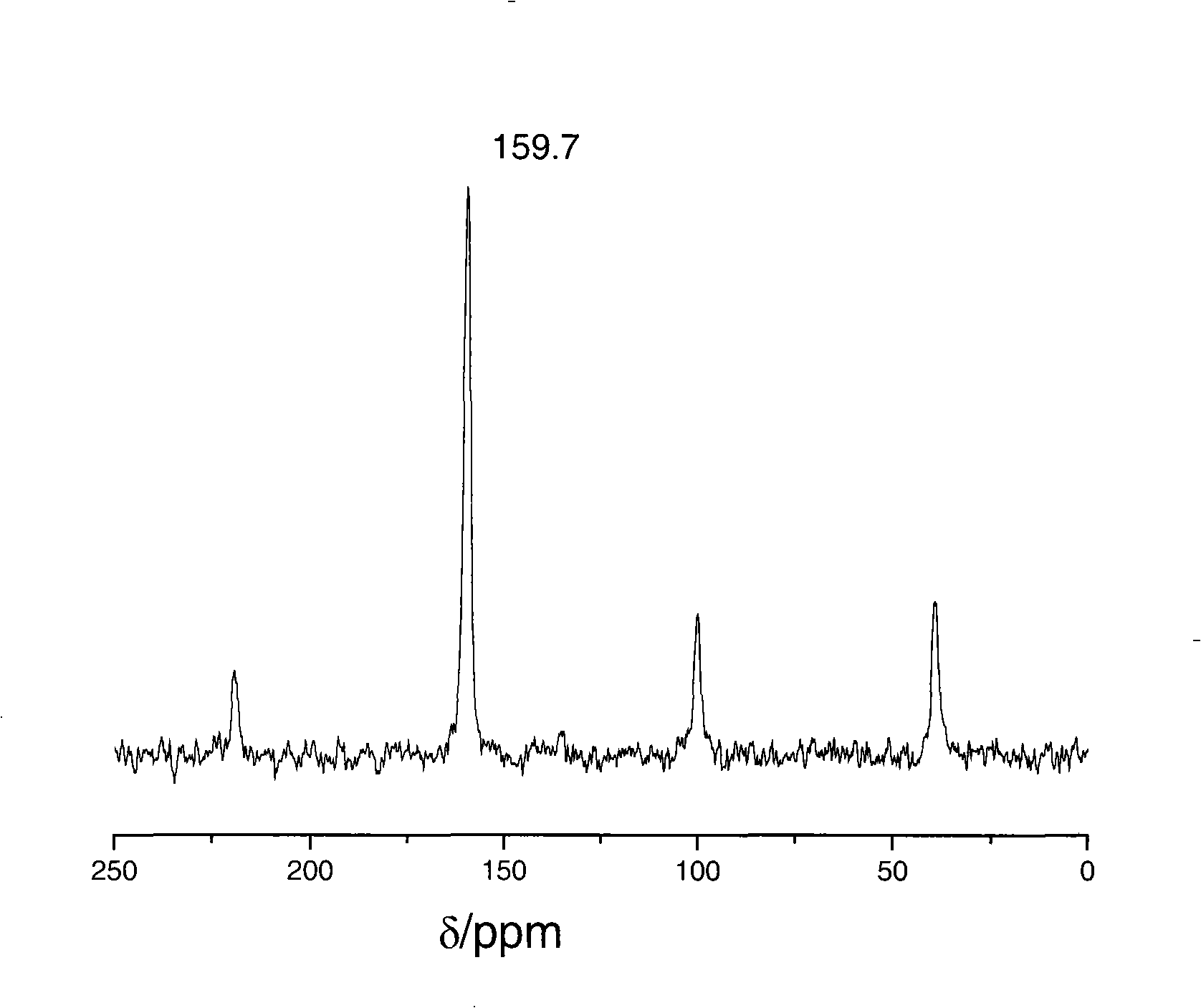

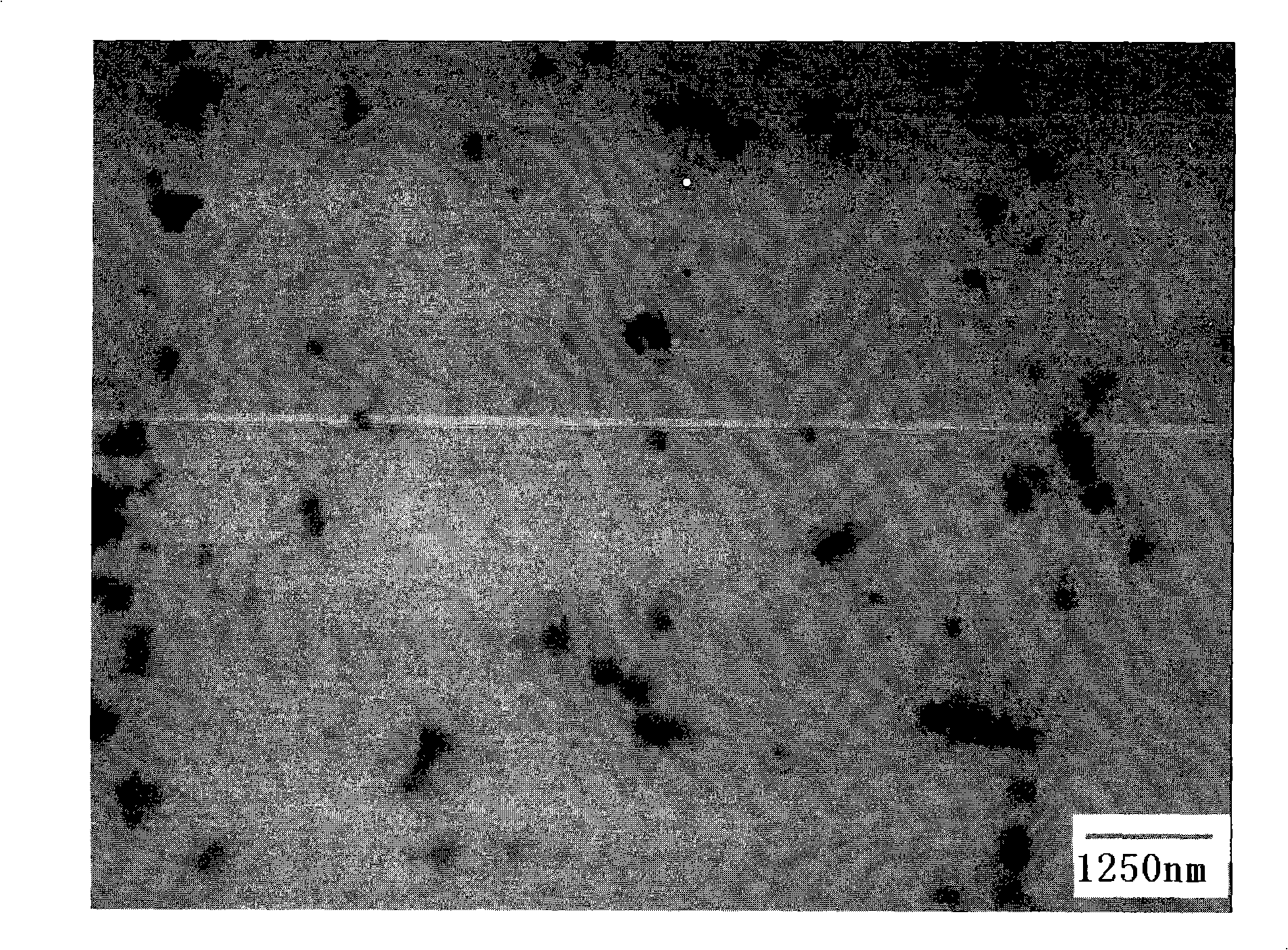

Image

Examples

Embodiment 1

[0014] Example 1: The porous silica carrier was added to the silane coupling agent dissolved in the ethanol solution, stirred at room temperature for 12 hours, and modified; the surfactant was added to the azodicarbonamide solution for refinement and modification. The modified carrier is impregnated with the modified foaming agent azodicarbonamide for 12 hours, and finally the composite foaming agent is dried at 60°C for 24 hours to obtain the finished composite foaming agent. The specific formula is shown in Table 1.

[0015] Table 1, azodicarbonamide / silica composite foaming agent formulation

[0016] recipe

Embodiment 2

[0017] Embodiment 2: the preparation method of 4,4'-oxidized diphenylsulfonyl hydrazine / silicon dioxide composite foaming agent described in embodiment 2 is the same as embodiment 1. The specific formula is shown in Table 2.

[0018] Table 2, 4,4'-diphenylsulfonyl hydrazine oxide / silica composite foaming agent formulation

[0019] recipe

Embodiment 3

[0020] Embodiment 3: The montmorillonite carrier is added to the silane coupling agent dissolved in the ethanol solution, stirred at room temperature for 12 hours, and modified, and then the pH of the mixed system is adjusted to PH=9 with sodium hydroxide solution; The active agent was added to the azodicarbonamide solution for refinement and modification; at 60 °C, the modified carrier was vigorously stirred with the modified foaming agent azodicarbonamide for 24 hours, and finally the composite was released. The foaming agent was dried at 60°C for 24 hours to obtain the finished product of the composite foaming agent. The specific formula is shown in Table 3.

[0021] Table 3, formula of azodicarbonamide / montmorillonite composite foaming agent

[0022] recipe

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com