Rubber member including aluminum-based metal component, and production method for the same

A manufacturing method and technology for metal parts, applied in metal layered products, chemical instruments and methods, metal material coating processes, etc., can solve problems such as difficulty in confirming, and achieve excellent followability, excellent followability, and time saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

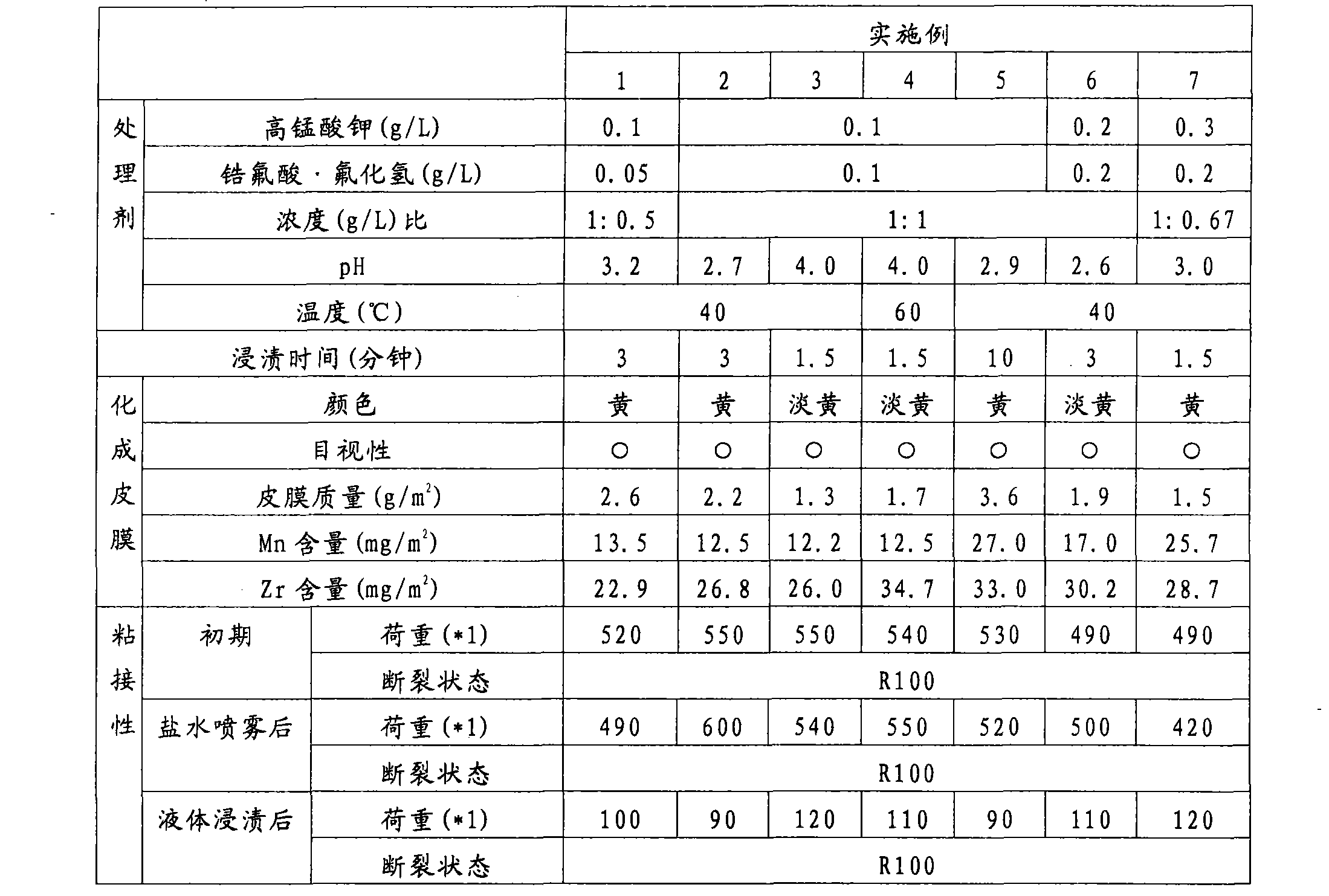

Embodiment 1

[0045] [Aluminum Metal Products]

[0046] A flat plate [25.4 mm×60 mm×3 mm (thickness)] made of aluminum alloy A6063 was prepared.

[0047] [Treatment agent for chemical film formation]

[0048] Mix 5.0 g of 2% by weight potassium permanganate aqueous solution and 5.0 g of 1% by weight zirconium fluoride hydrogen fluoride aqueous solution (by weight, zirconium fluoride: hydrogen fluoride = 1:1), and dilute the obtained mixed solution so that the Potassium manganate is 0.1 g / liter, and zirconium hydrofluoric acid·hydrogen fluoride is 0.05 g / liter. Its pH is 3.2. In this way, a treatment agent for chemical film formation was prepared.

[0049] [Formation of chemical film]

[0050] First, the entire surface of the above-mentioned aluminum-based metal product (flat plate) was immersed in an alkaline degreasing solution heated to 60° C. for degreasing. Then, the whole surface after this degreasing was blasted and roughened (the ten-point average roughness (Rz) was 20 μm). Nex...

Embodiment 2

[0053] [Treatment agent for chemical film formation]

[0054] Mix 5.0 g of 2% by weight potassium permanganate aqueous solution and 10.0 g of 1% by weight zirconium fluoride hydrogen fluoride aqueous solution (by weight, zirconium fluoride: hydrogen fluoride = 1: 1), and dilute the obtained mixed solution so that the Potassium manganate is 0.1 g / liter, and zirconium hydrofluoric acid·hydrogen fluoride is 0.1 g / liter. Its pH is 2.7. In this way, a treatment agent for chemical film formation was prepared.

[0055] [Formation of chemical film]

[0056] In the above-mentioned Example 1, the immersion into the treatment agent for forming the chemical conversion film was set at 40° C. for 3 minutes to form the chemical conversion film. Other than that, it is the same as the above-mentioned Example 1.

[0057] The manganese content derived from the manganese oxide in the formed above-mentioned chemical conversion film is 12.5 mg / m in terms of manganese atomic weight 2 , the cont...

Embodiment 3

[0059] [Treatment agent for chemical film formation]

[0060] Mix 5.0 g of 2% by weight potassium permanganate aqueous solution and 10.0 g of 1% by weight zirconium fluoride hydrogen fluoride aqueous solution (by weight, zirconium fluoride: hydrogen fluoride = 1: 1), and dilute the obtained mixed solution so that the Potassium manganate is 0.1 g / liter, and zirconium hydrofluoric acid·hydrogen fluoride is 0.1 g / liter. Furthermore, pH was adjusted to 4.0 by adding 28% ammonia water. In this way, a treatment agent for chemical film formation was prepared.

[0061] [Formation of chemical film]

[0062] In the above-mentioned Example 1, the immersion into the treatment agent for forming the chemical conversion film was set at 40° C. for 1.5 minutes to form the chemical conversion film. Other than that, it is the same as the above-mentioned Example 1.

[0063] The manganese content derived from the manganese oxide in the formed above-mentioned chemical conversion film is 12.2 mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com