Heat voice magnetic refrigeration low temperature system

A low-temperature system, magnetic refrigeration technology, applied in refrigerators, refrigeration and liquefaction, gas cycle refrigerators, etc., can solve the problem of large refrigeration temperature difference and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

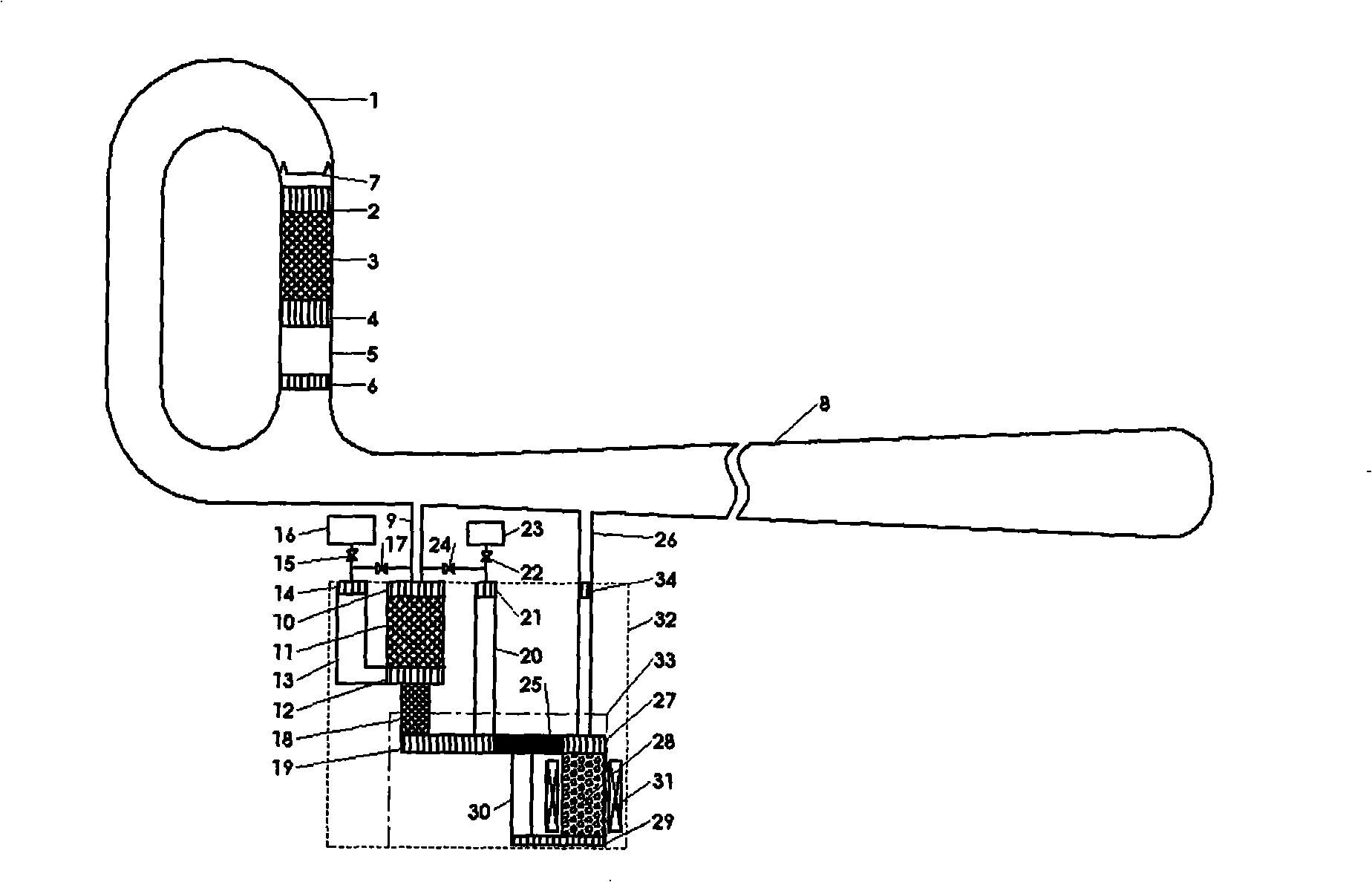

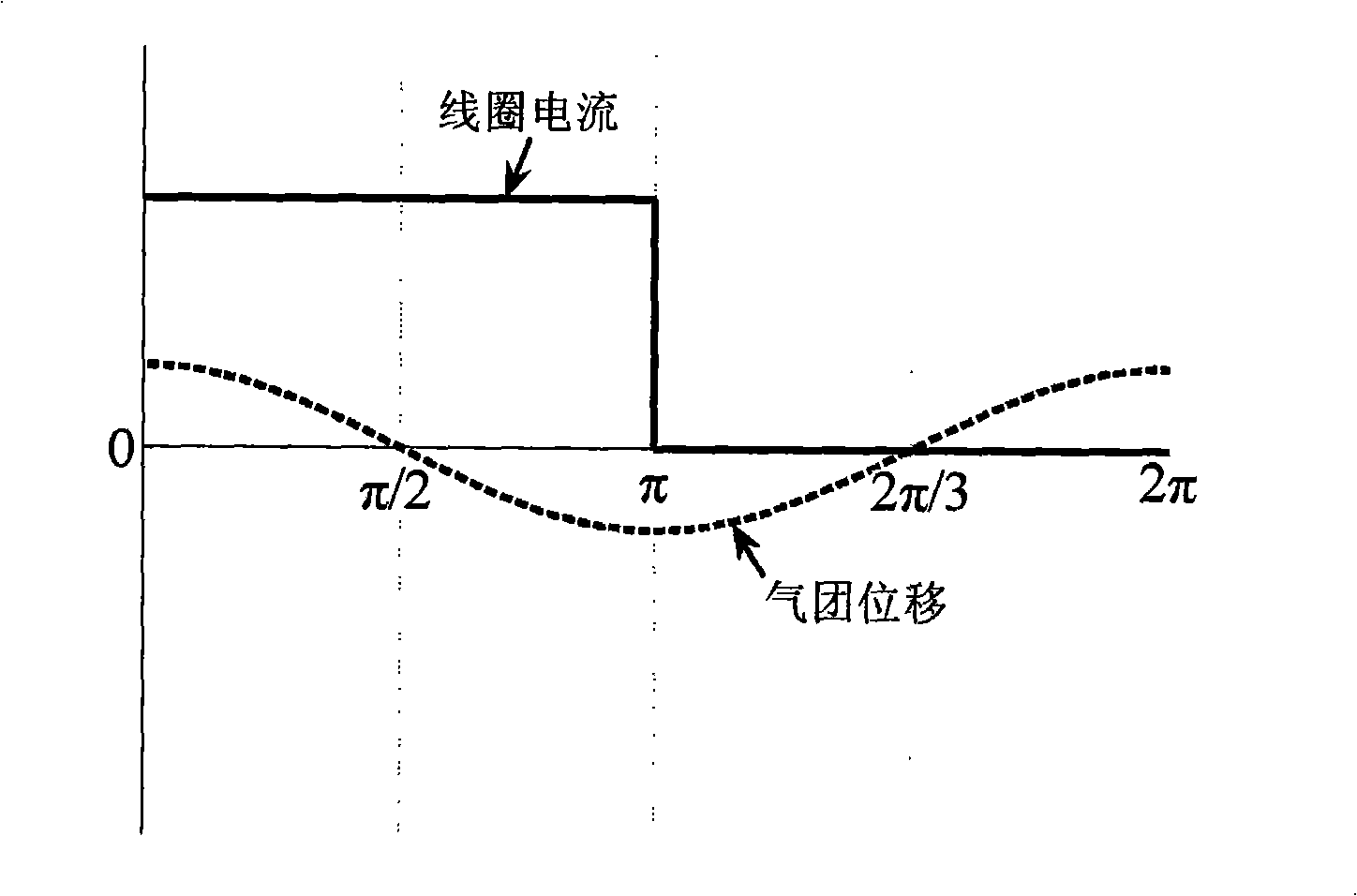

[0032] The structure of Example 1 is as follows figure 1 As shown, a thermoacoustic magnetic refrigeration cryogenic system with no moving parts includes a feedback tube (1), an elastic membrane (7), a room temperature end heat exchanger (2), a heat regenerator (3), and Heater (4), thermal buffer tube (5), room temperature end heat exchanger (6), resonance tube (8) at the tee, characterized in that it also includes a branch connected to the resonance tube (8) The U-shaped two-stage pulse tube refrigerator on the upper side and a magnetic refrigerator connected to the resonance tube (8) in the form of a branch. The two refrigerator systems are in a high-vacuum vacuum cover (32), of which there are two pulse tube refrigerators. The stage part and the magnetic refrigerator are located in the heat radiation screen (33). When heat enters the system from the heater (4), a temperature difference appears at both ends of the regenerator (3), and a temperature gradient is established in th...

Embodiment 2

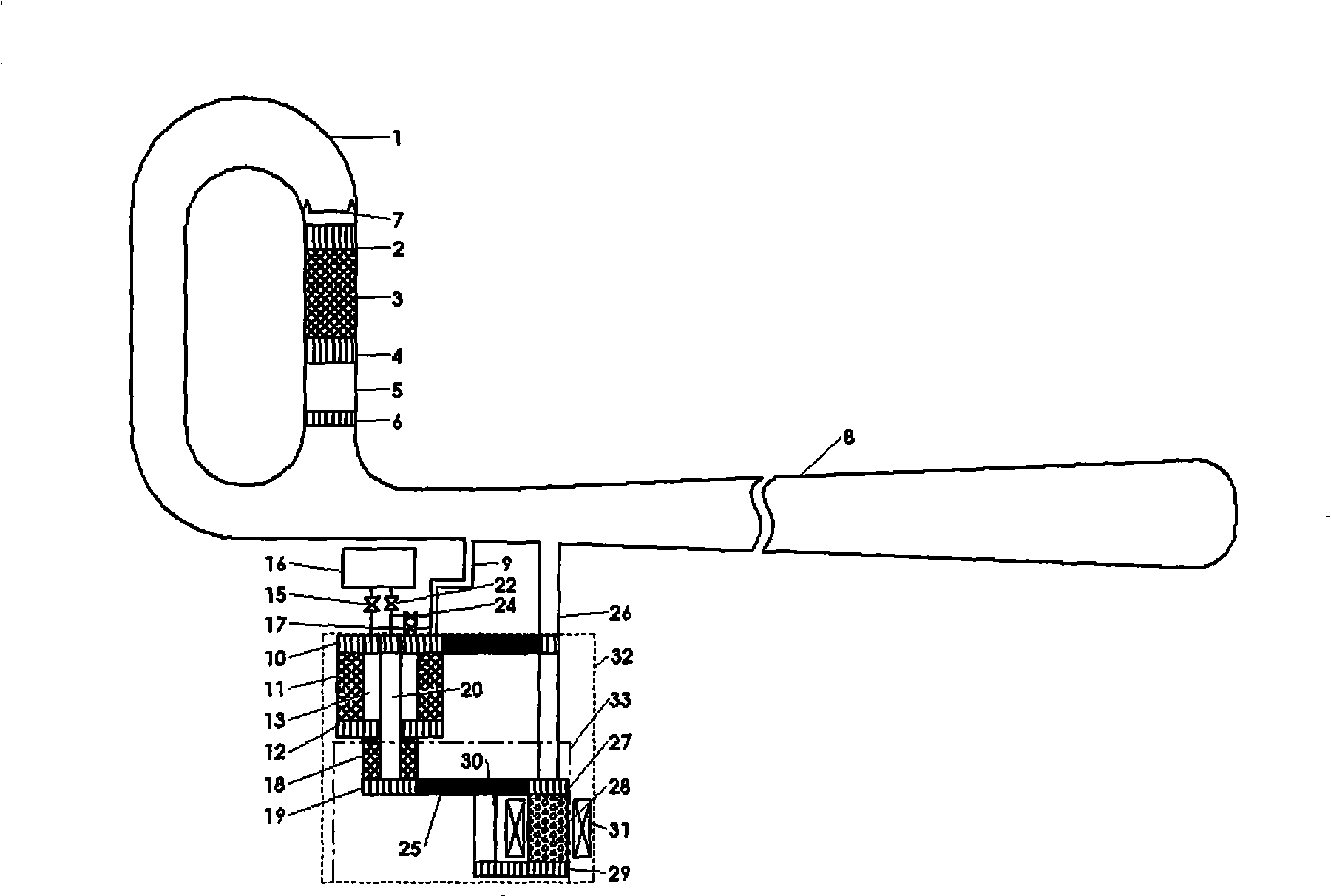

[0039] Such as image 3 As shown, this embodiment uses a coaxial two-stage pulse tube refrigerator on the basis of embodiment 1 to replace the ordinary two-stage pulse tube refrigerator in embodiment 1, and the first-stage gas store and the second-stage gas store Combined into a gas reservoir, the use of coaxial vessels can make the structure more compact. In this embodiment, the primary regenerator (11) is made into a ring shape, and the primary vessel (13) is placed in the middle of the primary regenerator and coaxially arranged with the primary regenerator (11), at room temperature The end heat exchanger (10) is divided into three parts by a first-stage regenerator (11), a first-stage pulse tube (13) and a second-stage pulse tube (20), and the gas flow passages between the parts are not connected to each other.

Embodiment 3

[0041] Such as Figure 4 As shown, this embodiment adopts a single-stage U-shaped pulse tube refrigerator as the pre-cooling of the magnetic refrigerator, which can realize a low temperature device without moving parts in a higher temperature range of 120K to 20K.

[0042] It is easy to understand that a single-stage pulse tube refrigerator can also be arranged in a coaxial type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com