Second confocal measuring method and apparatus based on movable phase interfere

A technology of phase-shifting interferometry and measurement method, which is applied in the field of ultra-precision non-contact fast and large-scale scanning measurement, which can solve the problems of measuring surface reflectivity difference, axial response signal measurement sensitivity is not high, and only relative displacement change can be obtained. , to achieve the effect of a large range of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

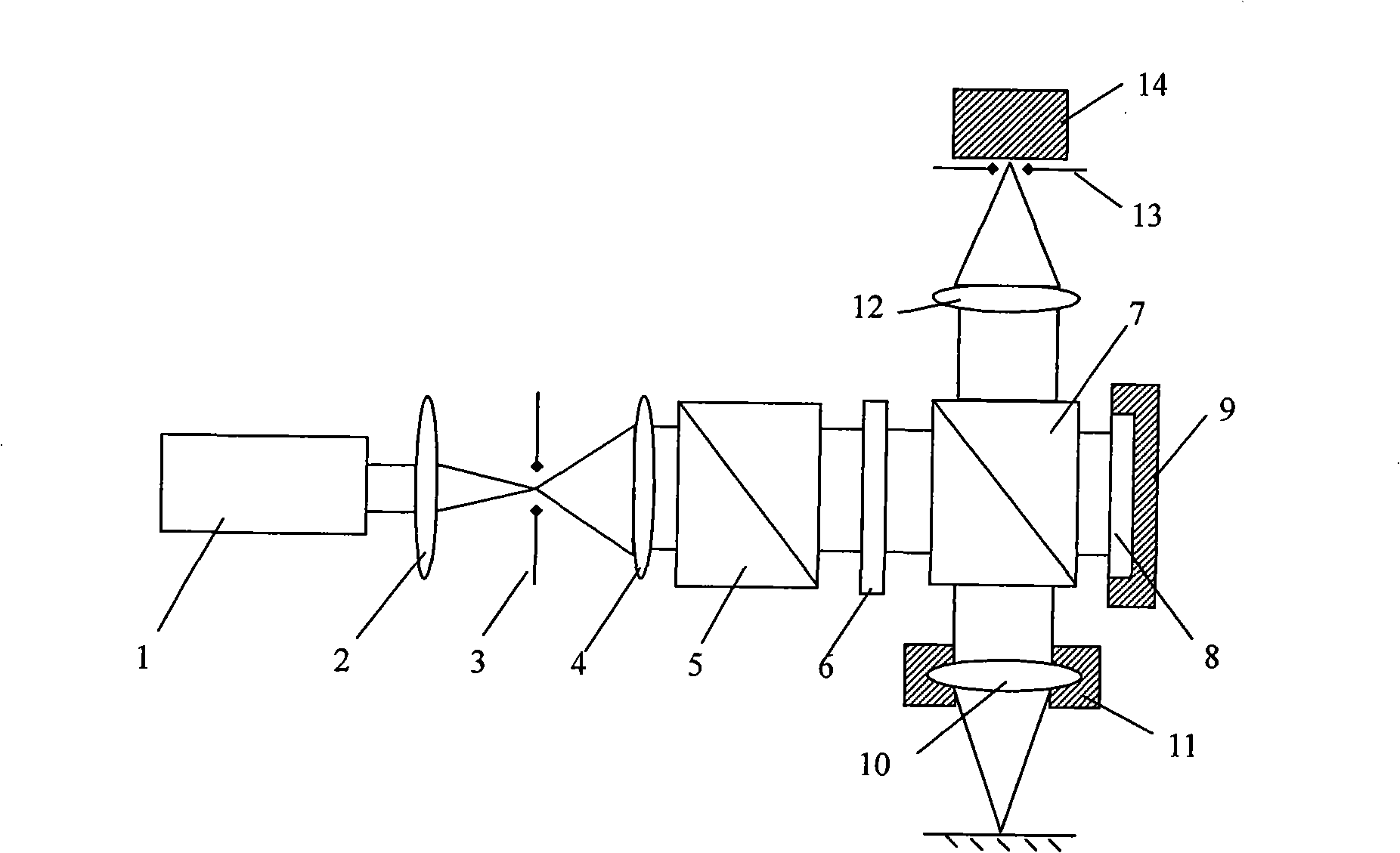

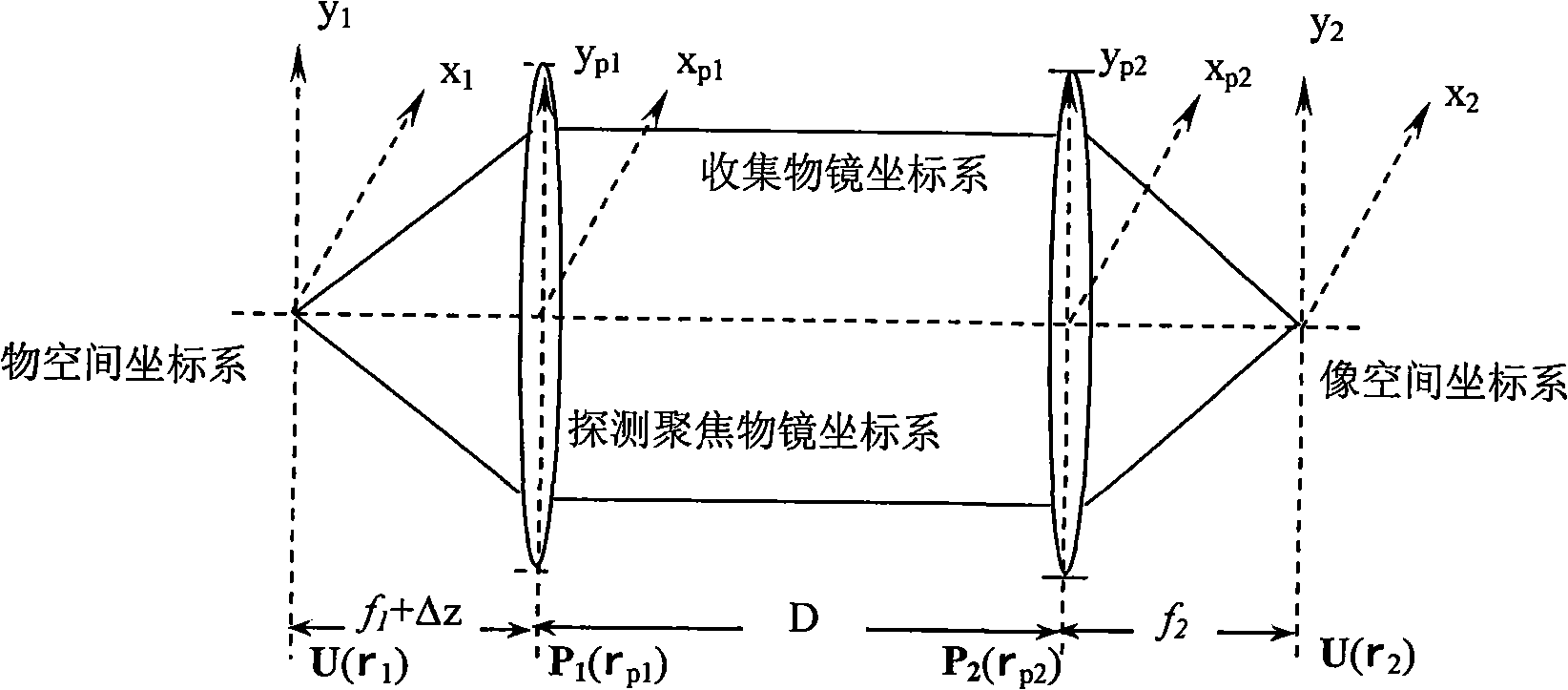

[0030] Such as figure 1 As shown, the present invention provides a secondary confocal measurement device based on phase shifting interference including: a laser 1; a collimating and focusing objective lens 2; a first pinhole 3; a collimating beam expanding objective lens 4; A wave plate 6; a beam splitter 7; a mirror 8; a first micro-driver 9; a detection focusing objective lens 10; a second micro-driver 11; a collecting objective lens 12; a second pinhole 13;

[0031] Concrete implementation steps of the present invention:

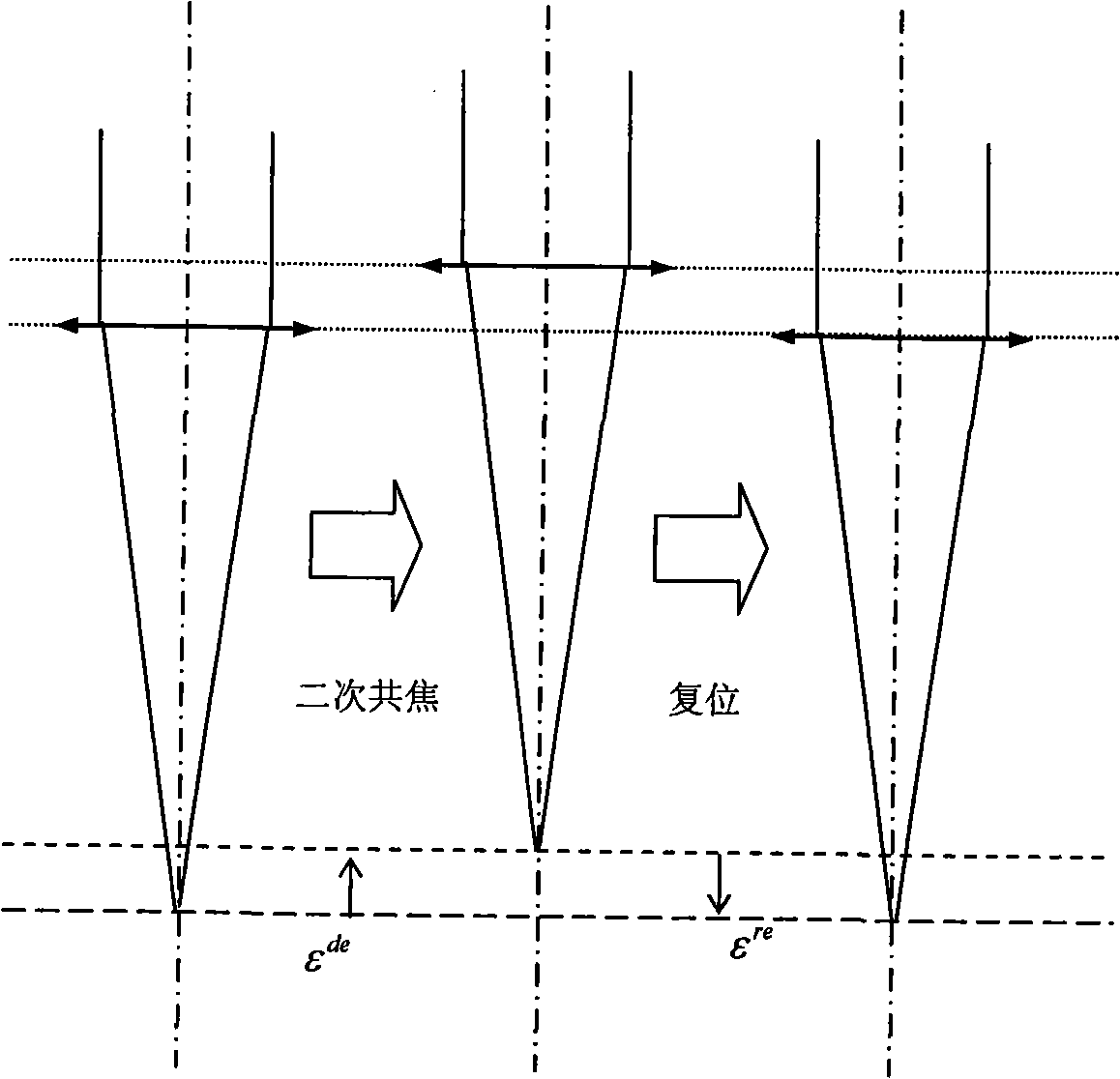

[0032] In the first step, in the first confocal state, the phase of the measurement light relative to the reference light is calculated

[0033] Such as figure 1As shown, the laser 1 emits a linearly polarized light beam, which becomes an approximate ideal plane wave after passing through the collimating beam expander lens group formed by the collimating focusing objective lens 2, the first pinhole 3, and the collimating beam expanding objective lens 4;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com