Hollow titanium oxide high colour electrophoresis particle for electrophoresis display and preparation thereof

A dark color electrophoresis and electrophoretic display technology, which is applied in the preparation of titanium dioxide, titanium oxide/hydroxide, and microspheres, to achieve the effects of easy control of particle size, regular shape, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0013] ① Disperse 0.10 g of methyl methacrylate polymer hollow microspheres in 95 mL of absolute ethanol, add 0.90 g of deionized water, stir, and react at 40 °C for 30 min. Stand still in an oven at 70°C for 96 hours to obtain a white powder, which is a spherical hollow polymer / titanium dioxide composite particle.

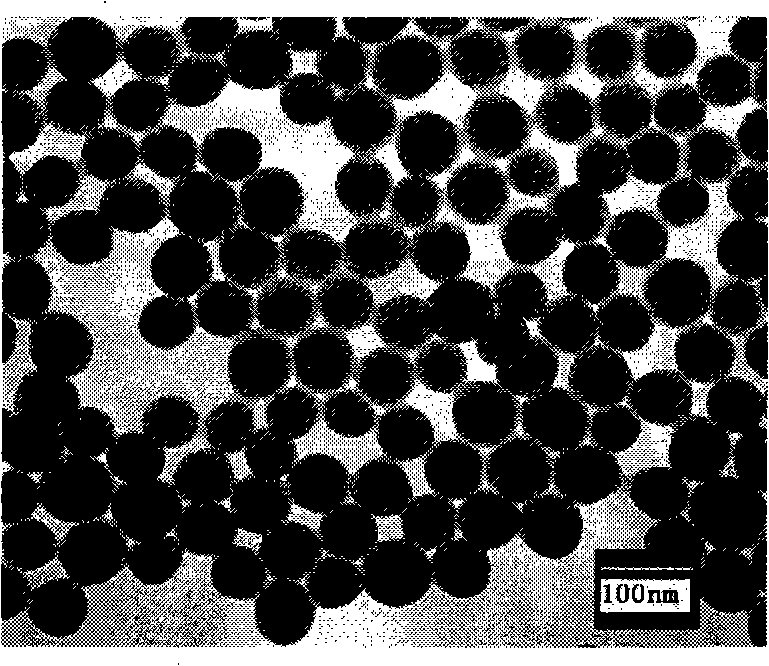

[0014] ②The prepared white hollow polymer / titanium dioxide composite particles were calcined at 1000°C for 5 hours in an ammonia atmosphere to obtain black hollow TiO spherical particles with a particle size of 170nm and a relative density of 1.77g / cm 3 .

example 2

[0016] ① Disperse 0.20g of polystyrene hollow microspheres in 90mL of absolute ethanol, add 1.03g of deionized water, stir, react at 40°C for 30min, and stand in an oven at 70°C for 96h to obtain a white powder, which is a spherical hollow polymer / Titanium dioxide composite particles.

[0017] ②The prepared white hollow polymer / titanium dioxide composite particles were calcined at 600°C for 3 hours in a hydrogen atmosphere to obtain blue-black hollow TiO2 particles. 0.93 Spherical particles with a uniform particle size of 215nm and a relative density of 1.59g / cm 3 .

example 3

[0019] ① Disperse 0.50g of ethyl methacrylate polymer hollow microspheres in 90mL of absolute ethanol, add 1.03g of deionized water, stir, react at 40°C for 30min, and stand in an oven at 80°C for 96h to obtain a white powder, which is spherical Hollow polymer / titanium dioxide composite particles.

[0020] ②The prepared white hollow polymer / titanium dioxide composite particles were calcined at 800°C for 4 hours in an ammonia atmosphere to obtain purple-black hollow TiO2 particles. 0.97 Spherical particles with a uniform particle size of 253nm and a relative density of 1.71g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap