A kind of preparation method of liquid polycarbosilane

A polycarbosilane, liquid technology, applied in the field of preparation of liquid polycarbosilane, can solve the problems of limiting the large-scale preparation and application of liquid polycarbosilane, difficult control of the reaction process, difficult operation, etc., to avoid expensive and free carbon content. low, safety-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

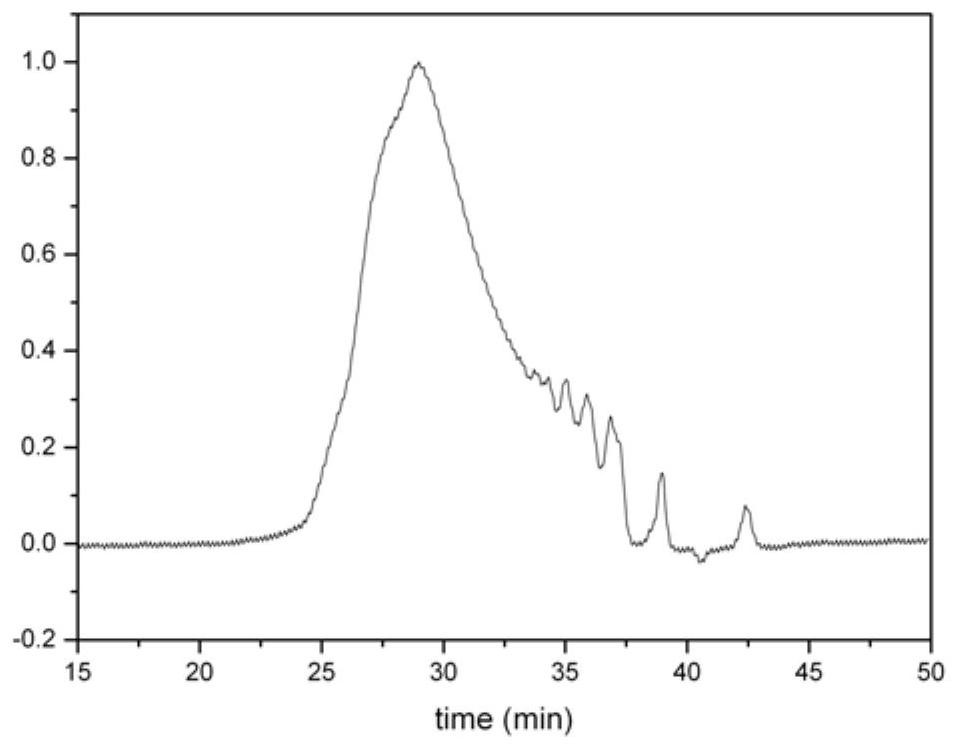

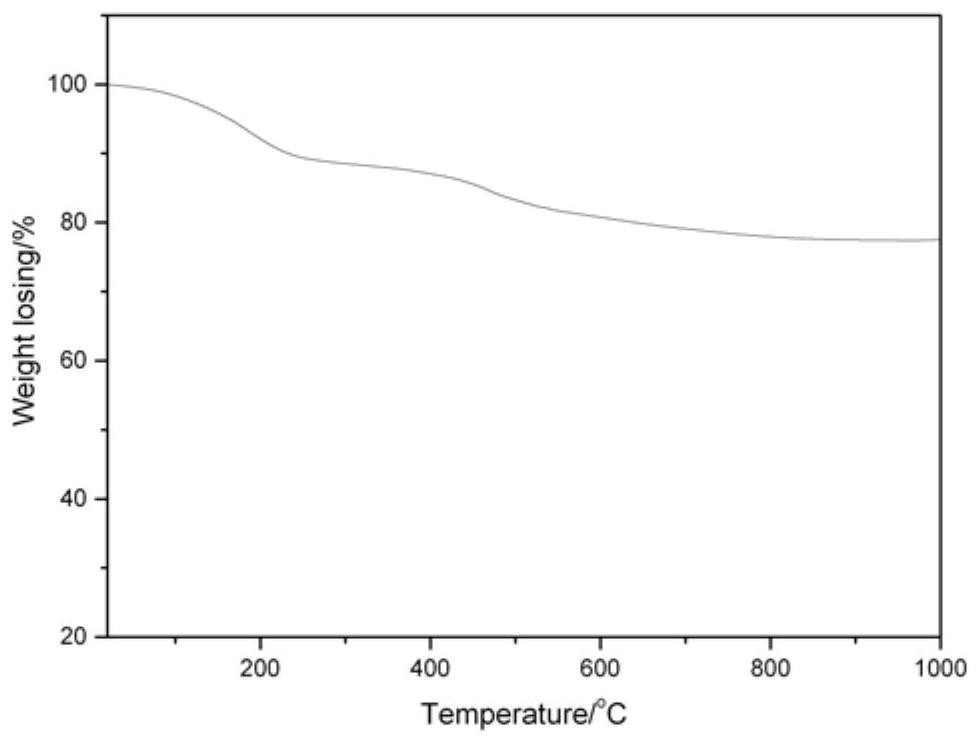

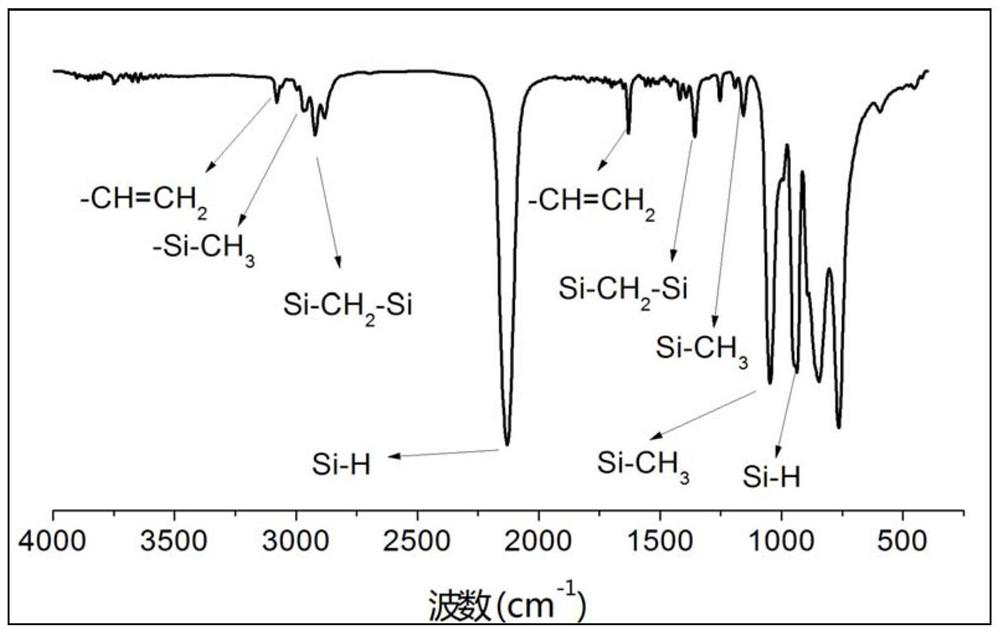

Examples

Embodiment 1

[0032] (1) Add 184 grams of chloromethyltrichlorosilane and 282 grams of hexamethyldisilazane to the Schlenk reactor filled with an inert gas atmosphere in advance, and stir to mix the raw materials uniformly, then raise the temperature to 50 ° C, stir And react for 12 hours;

[0033] (2) Add 28 grams of activated magnesium chips into the purified and dried tetrahydrofuran, and add the material obtained in step (1), 7.6 grams of allyl chloride and 200 mL of tetrahydrofuran through a dropping funnel. After stirring for 1 hour, a mixed solution of 16.3 g of chloromethylmethyldichlorosilane and 100 mL of tetrahydrofuran was added to the system using a dropping funnel, and the temperature of the system was raised to 60° C., stirred and reacted for 12 hours.

[0034] (3) Add 19 grams of sodium borohydride, and the reaction temperature is 60°C. Stir for 12 hours after addition of sodium borohydride is complete.

[0035](4) Add petroleum ether, deionized water and concentrated hydr...

Embodiment 2

[0040] (1) Add 184 grams of chloromethyltrichlorosilane and 241.5 grams of hexamethyldisilazane into a Schlenk reactor filled with an inert gas atmosphere in advance, and stir to mix the raw materials uniformly, then raise the temperature to 50 ° C, and stir And react for 12 hours;

[0041] (2) Add 28 grams of activated magnesium chips into the purified and dried tetrahydrofuran, and add the material obtained in step (1), 7.6 grams of allyl chloride and 200 mL of tetrahydrofuran through a dropping funnel. After stirring for 1 hour, a mixed solution of 16.3 g of chloromethylmethyldichlorosilane and 100 mL of tetrahydrofuran was added to the system using a dropping funnel, and the temperature of the system was raised to 60° C., stirred and reacted for 12 hours.

[0042] (3) Add 19 grams of sodium borohydride, and the reaction temperature is 60°C. Stir for 12 hours after addition of sodium borohydride is complete.

[0043] (4) Add petroleum ether, deionized water and concentrat...

Embodiment 3

[0046] (1) Add 184 grams of chloromethyltrichlorosilane and 282 grams of hexamethyldisilazane to the Schlenk reactor filled with an inert gas atmosphere in advance, and stir to mix the raw materials uniformly, then raise the temperature to 50 ° C, stir And react for 12 hours;

[0047] (2) Add 28 grams of activated magnesium chips into the purified and dried tetrahydrofuran, and add the material obtained in step (1), 7.6 grams of allyl chloride and 200 mL of tetrahydrofuran through a dropping funnel. After stirring for 1 hour, a mixed solution of 14 g of chloromethylmethylchlorosilane and 100 mL of tetrahydrofuran was added to the system using a dropping funnel, and the temperature of the system was raised to 60° C., stirred and reacted for 12 hours.

[0048] (3) Add 19 grams of sodium borohydride, and the reaction temperature is 60°C. Stir for 12 hours after addition of sodium borohydride is complete.

[0049] (4) Add petroleum ether, deionized water and concentrated hydroch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com