Slicing apparatus

A slicer and fixed blade technology, applied in the field of slicing equipment, can solve the problems of difficult collection and transportation, complex production process, high operation requirements, etc., and achieve the effect of convenient collection and transportation, simple operation process and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

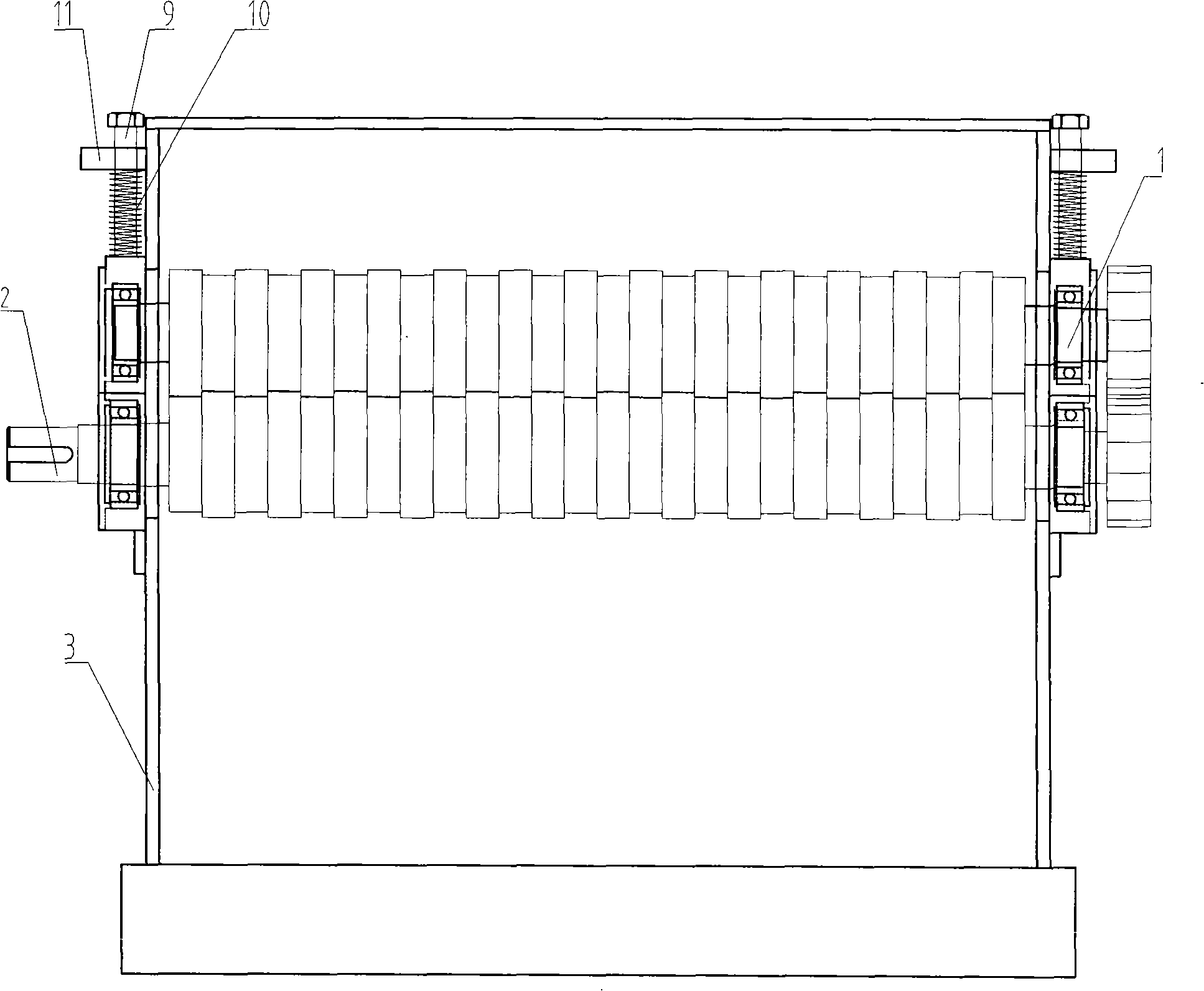

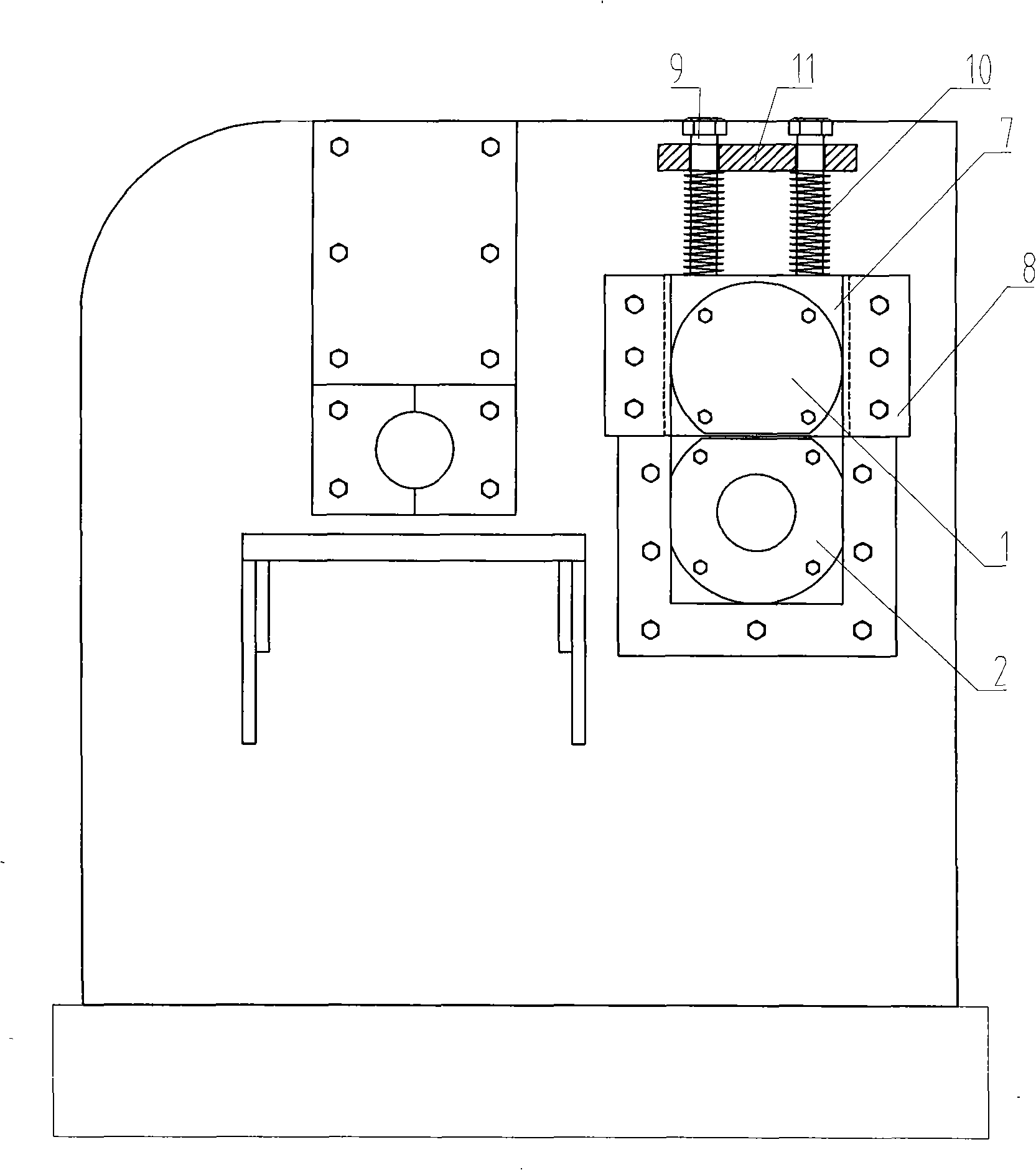

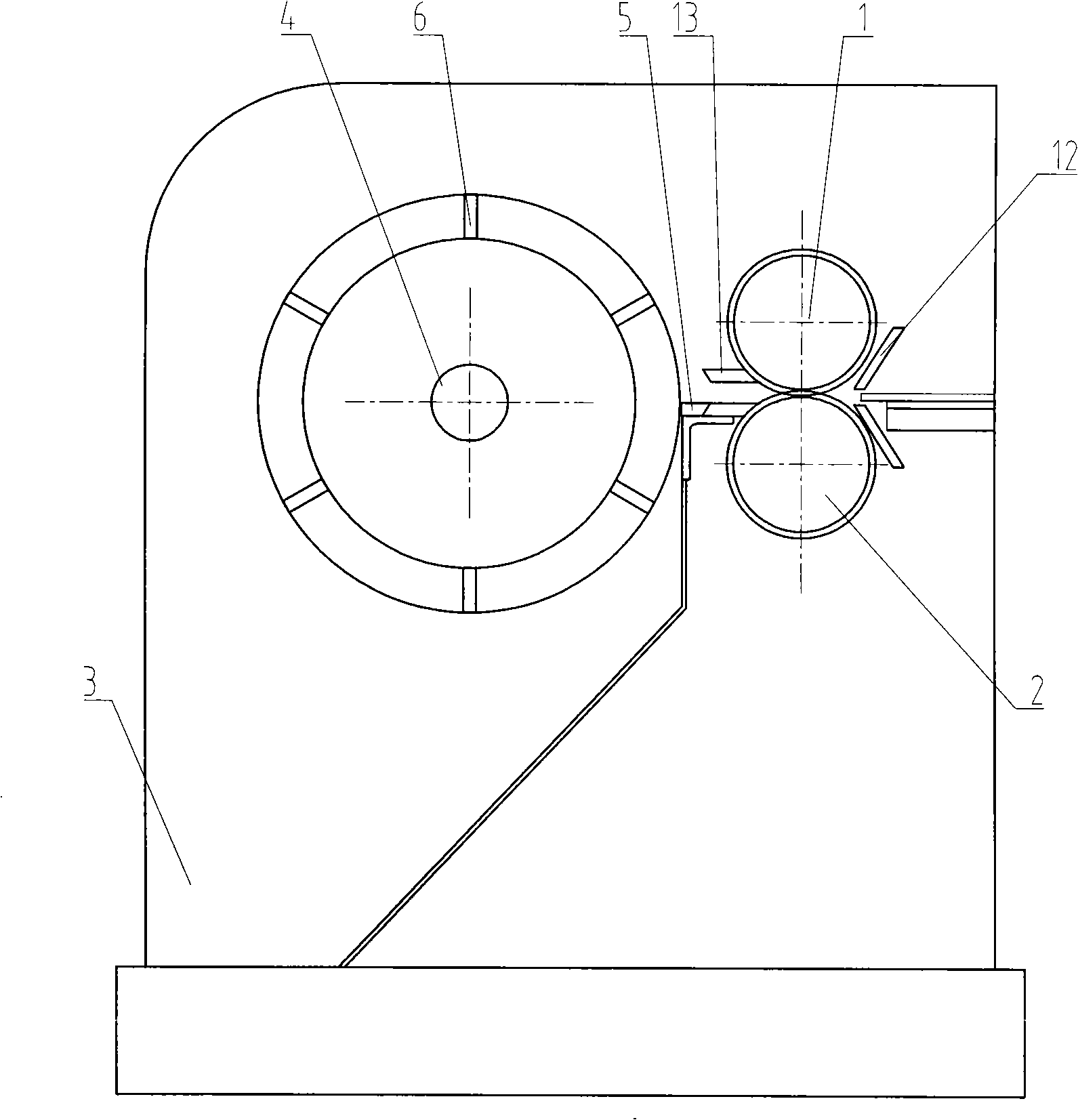

[0016] Such as figure 1 , 3 As shown, a slicing machine has a pair of driven rollers 1 and driving rollers 2 engaged up and down for cutting the plate into strips, and the discharging side of the driving roller 2 and driven roller 1 is provided with a spiral cutting roller 4 , the bracket between the drive roller 2 and the spiral cutting roller 4 is horizontally provided with a fixed blade 5, and the spiral cutting roller 4 is provided with a movable blade that is adapted to the fixed blade 5 and is used to cut the strip material into a square sheet material. The blade 6, the entrance where the driven roller 1 and the driving roller 2 mesh are provided with a protective plate 12, and the protective plate 12 is fixed on the support plate 3, and the outlet is provided with a stopper 13, and the stopper 13 is fixed on the support plate 3 .

[0017] Such as figure 1 , 2 As shown, the two ends of the driving roller 2 are provided with an upright support plate 3, and the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com