Method for fermenting alcohol directly by beet

An alcoholic fermentation and sugar beet technology, applied in fermentation, biofuel and other directions, can solve the problems of decreased alcoholic fermentation power, affecting normal production, impure products, etc., and achieves the effects of high alcohol yield, low cost and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

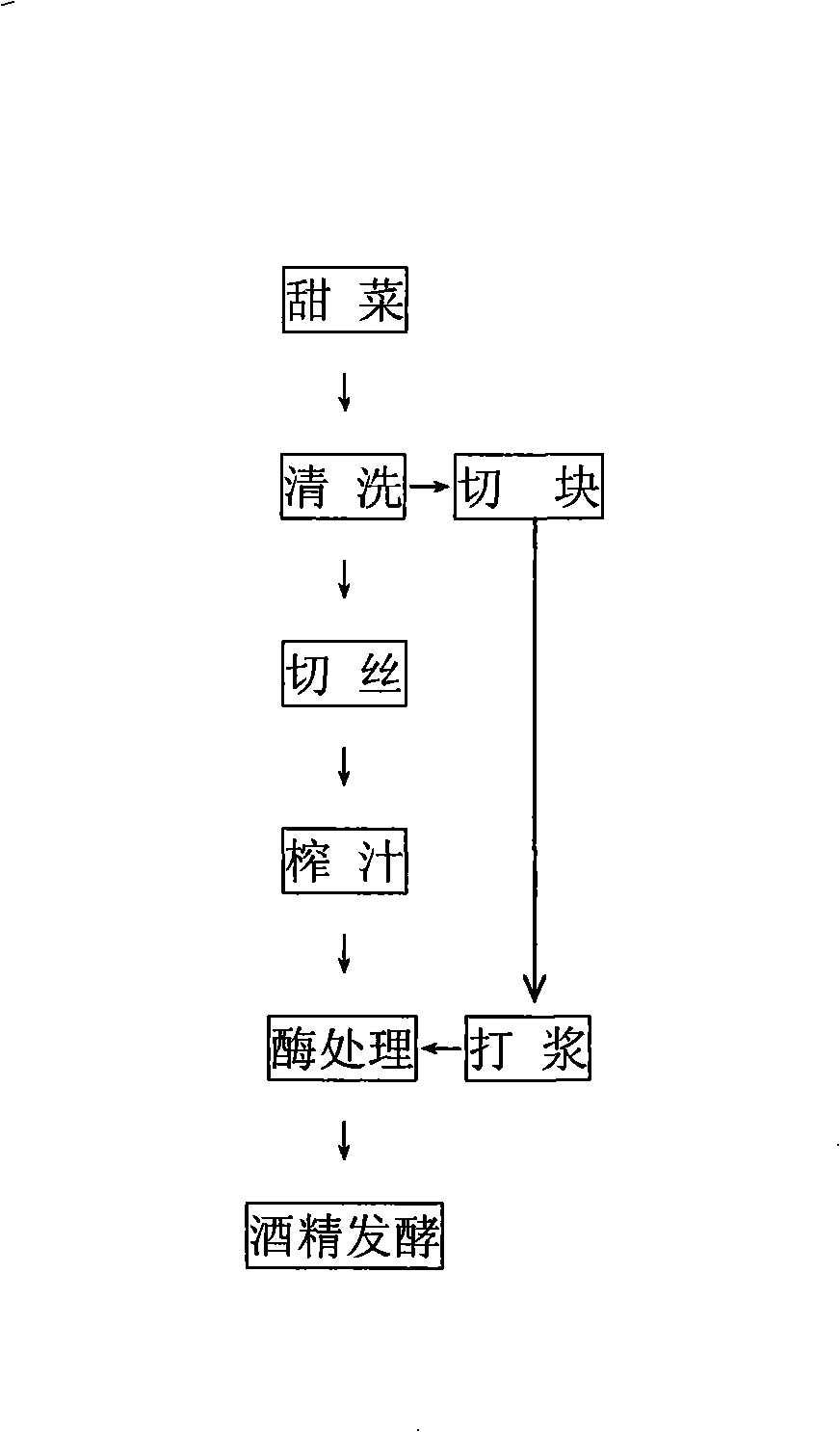

Method used

Image

Examples

Embodiment 1

[0015] Example 1: A. Preparation of beet juice: cut the cleaned beet tubers into pieces, squeeze the juice at 70°C to obtain beet juice, and soak the residue at 70°C to extract the extract Blend with beet juice in a conventional way or concentrate to make the sugar brix of the mixed liquid reach 14-17 Blix.

[0016] B. Enzyme treatment: Since the squeezed juice contains a certain amount of pectin, it will affect the normal progress of fermentation, so a certain amount of pectinase needs to be added to remove pectin. In this process, the pectinase is added in an amount of 0.2% (v / v), and left to act at a temperature of 50-60° C. for 1 hour, and then it can be used for alcoholic fermentation.

[0017] C. Alcoholic fermentation: Put the treated beet juice into a fermenter and use active dry yeast or immobilized yeast to carry out alcoholic fermentation. The fermentation temperature is 28-35°C and the fermentation time is 48-60h.

[0018] The results showed that when the sugar br...

Embodiment 2

[0019] Embodiment 2: beet tubers are cut into pieces after cleaning, beat into pulp with a beater, adjust the pH value to between 5.0-6.2, and then add 5% compound enzyme liquid wherein, the compound enzyme liquid consists of pectinase, Composed of cellulase and glucoamylase, the volume ratio of each enzyme solution is 2:2:1, heat preservation at 55°C for 1 hour, put into the fermentation tank and use active dry yeast or immobilized proliferating yeast for alcoholic fermentation, the fermentation temperature 32°C, fermentation time 54h.

[0020] The results showed that the reducing sugar of beet pulp after treatment was 16.4g / 100ml, the alcohol content in fermented mash reached 8.6% (v / v) after alcoholic fermentation, and the residual total sugar was 1.6g / 100ml.

Embodiment 3

[0021] Example 3: Repeat Example 2, with the following differences: the addition of the compound enzyme solution is 3%, and it is incubated at a temperature of 60° C. for 1 hour, and put into a fermenter to carry out alcoholic fermentation with active dry yeast or immobilized proliferating yeast , the fermentation temperature is 35°C, and the fermentation time is 60h.

[0022] The results showed that the alcohol content in the fermented mash reached 8.2% (v / v), and the residual total sugar was 1.7g / 100mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com