Wood automatic monitoring method and system

An automatic monitoring, wood technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of calculating diameter class, inability to follow, extraction, etc., to achieve the effect of rapid measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

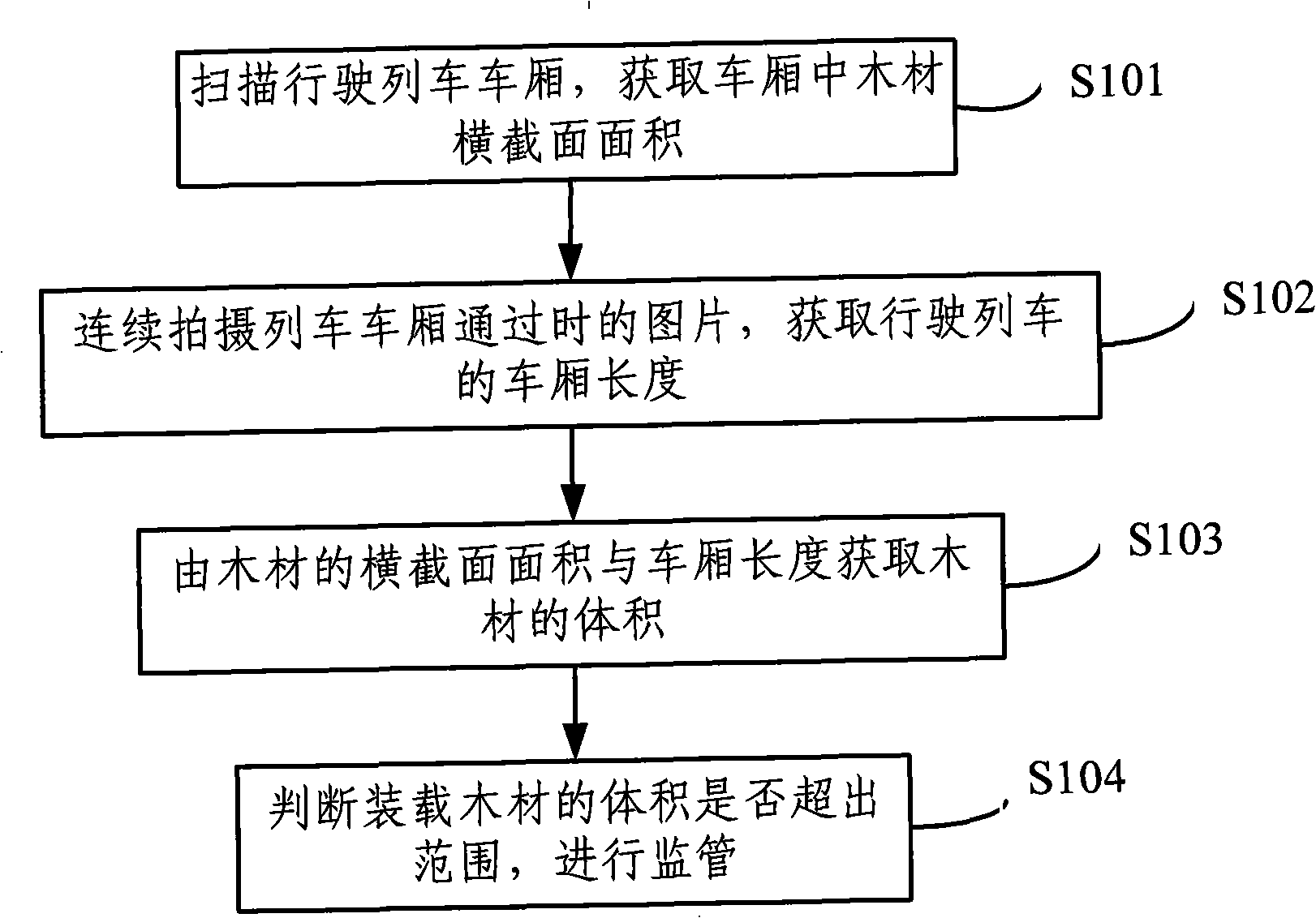

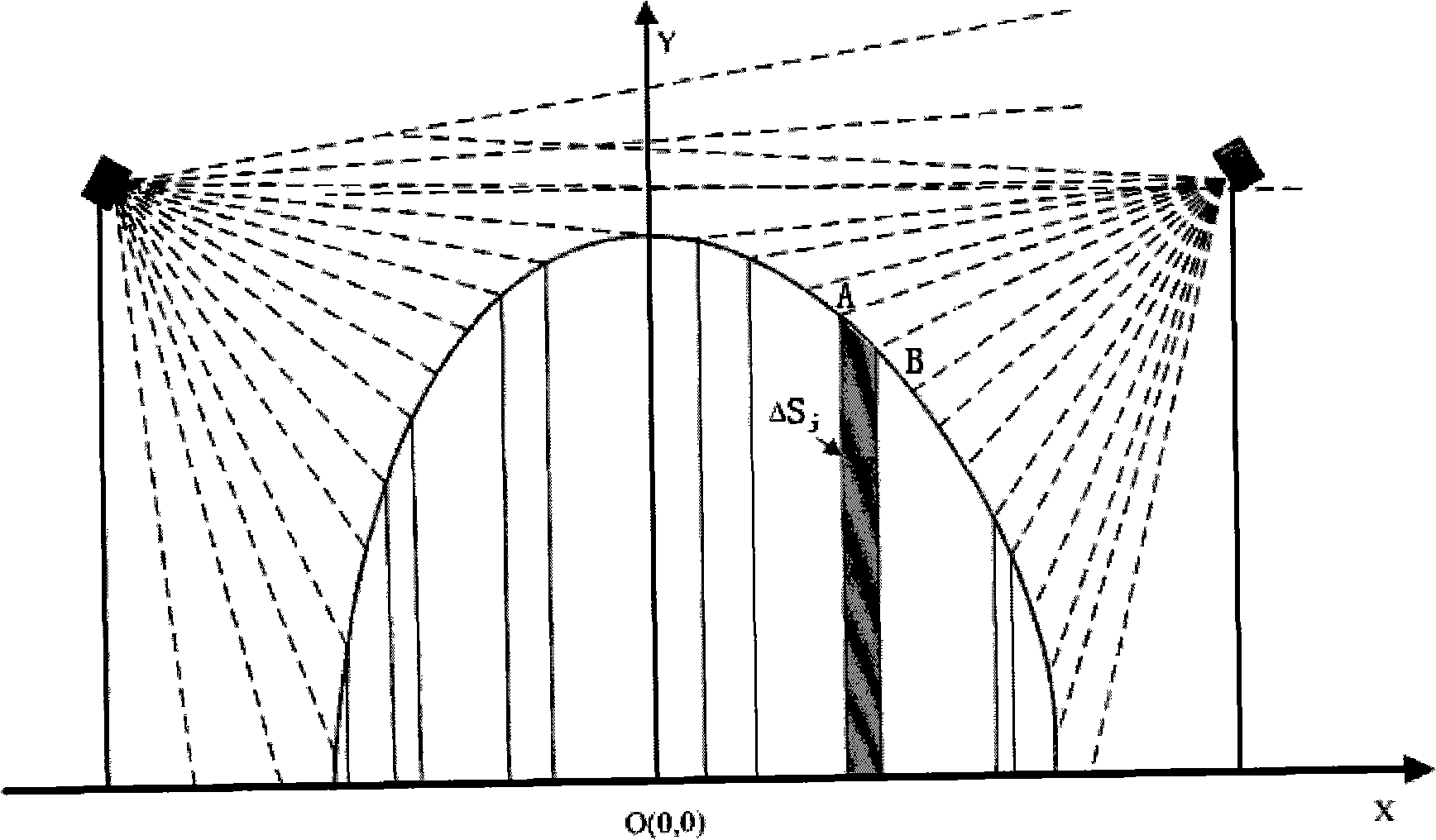

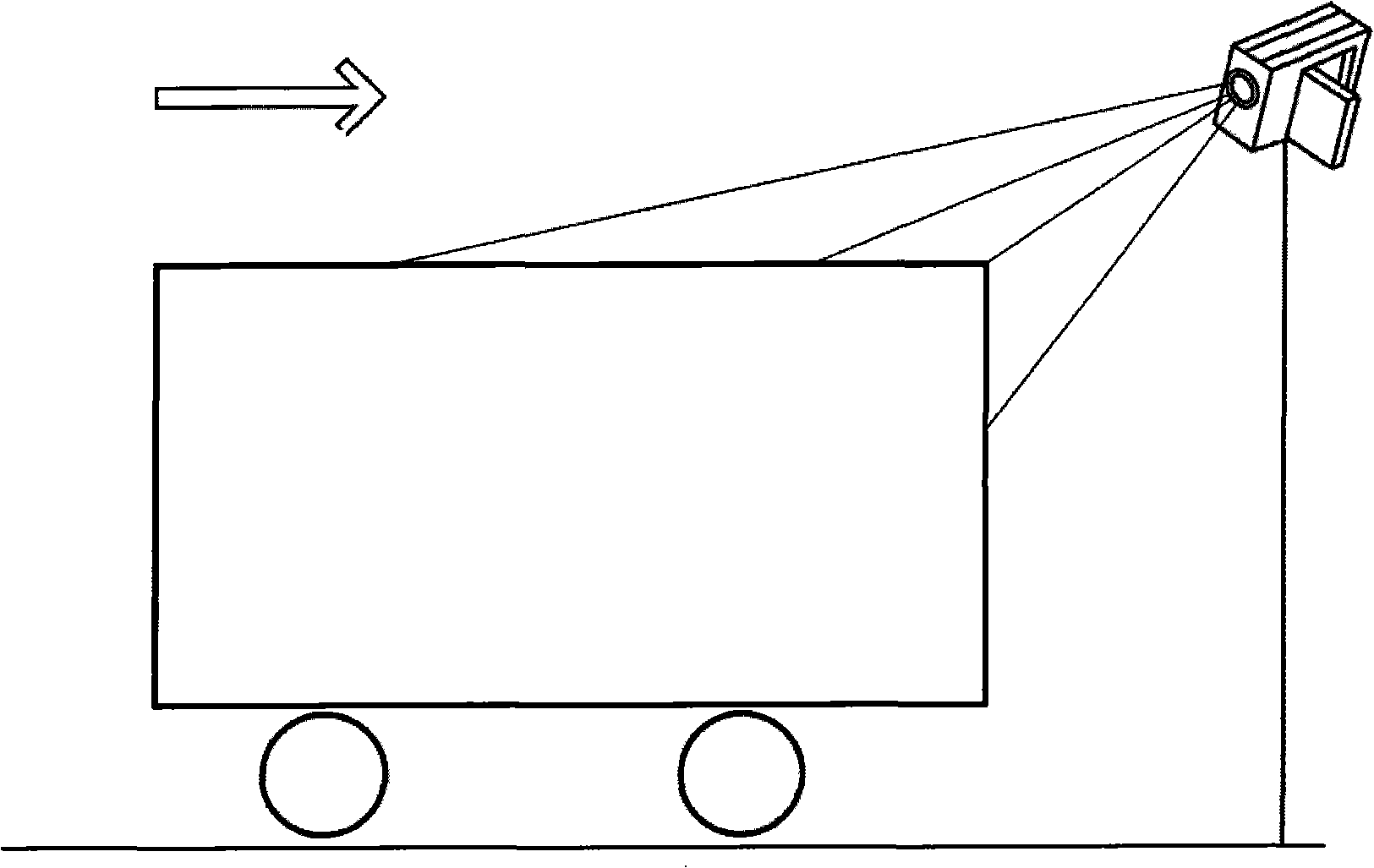

[0037] Such as figure 1 Shown is a flow chart of an automatic timber supervision method for loading timber on moving vehicles. The method is used to supervise timber loaded on a moving train. The method mainly includes steps: step S101, scanning the traveling train compartment with a laser scanning device to obtain the compartment According to the contour line data of the cross-section of the wood, the cross-sectional area of the wood is obtained according to the contour line data; step S102, using the camera device to continuously take pictures of the train carriages passing by, and obtain the length of the carriages of the running train according to the photographed pictures ; Step S103, obtain the volume of the wood from the cross-sectional area of the wood and the length of the carriage; Step S104, judge whether the volume of the wood obtained is out of range, and supervise. The steps in this embodiment are described in detail below way of realization.

[0038] Step S...

Embodiment 2

[0079] The wood automatic supervision method provided in this embodiment is used to supervise the logs loaded in the stockyard or the stationary vehicles. Since the wood is stationary, the laser scanning device cannot be used to obtain the contour line. The end face of the wood is recognized by the image processing method, and the calculated The cross-sectional area of each piece of wood.

[0080] Such as Figure 6 It is a flow chart of the automatic timber supervision method for stockyard logs and stationary trains loading logs in the present invention, the method includes the following steps: step S201, using a camera device to capture the end face image of the stockyard logs or the loaded logs, according to the The end face image obtains the number of logs and the cross-sectional area of each log; step S202, uses a scale to measure the length of the log; step S203, obtains the log in the yard from the number of logs, the cross-sectional area of each log, and the lengt...

Embodiment 3

[0109] Since the embodiment 2 of the present invention proposes the method of obtaining the end face image of the log to obtain the cross-sectional area of each log, the automatic supervision of the loaded timber of the driving vehicle can also be adopted Figure 7 In the manner shown, the running train is a train, and X-1, X, and X+1 represent different carriages, which are loaded with wood, and three cameras are respectively installed at different positions above the train track, cameras C1 and C3 It is used to shoot the end face image of the wood in the carriage. C1 and C3 are located above the rail, and they are tilted at a certain angle to shoot the rear and front face images respectively. The cameras C2 and C4 are located on both sides above the rail and are used to continuously take pictures of the carriage passing through. The length of the compartment, the cameras C1, C2, C3, and C4 are respectively connected to the image acquisition device 1, and the image acquisiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com