System and method for testing locomotive general-purpose circuit board function

A general-purpose circuit and functional testing technology, applied in the direction of electronic circuit testing, etc., can solve the problems of inability to meet the requirements of dual 96-pin and 96+48-pin interfaces of locomotive circuit boards, difficulty in precision measurement, and inability to hardware self-test, etc. Low, high precision, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

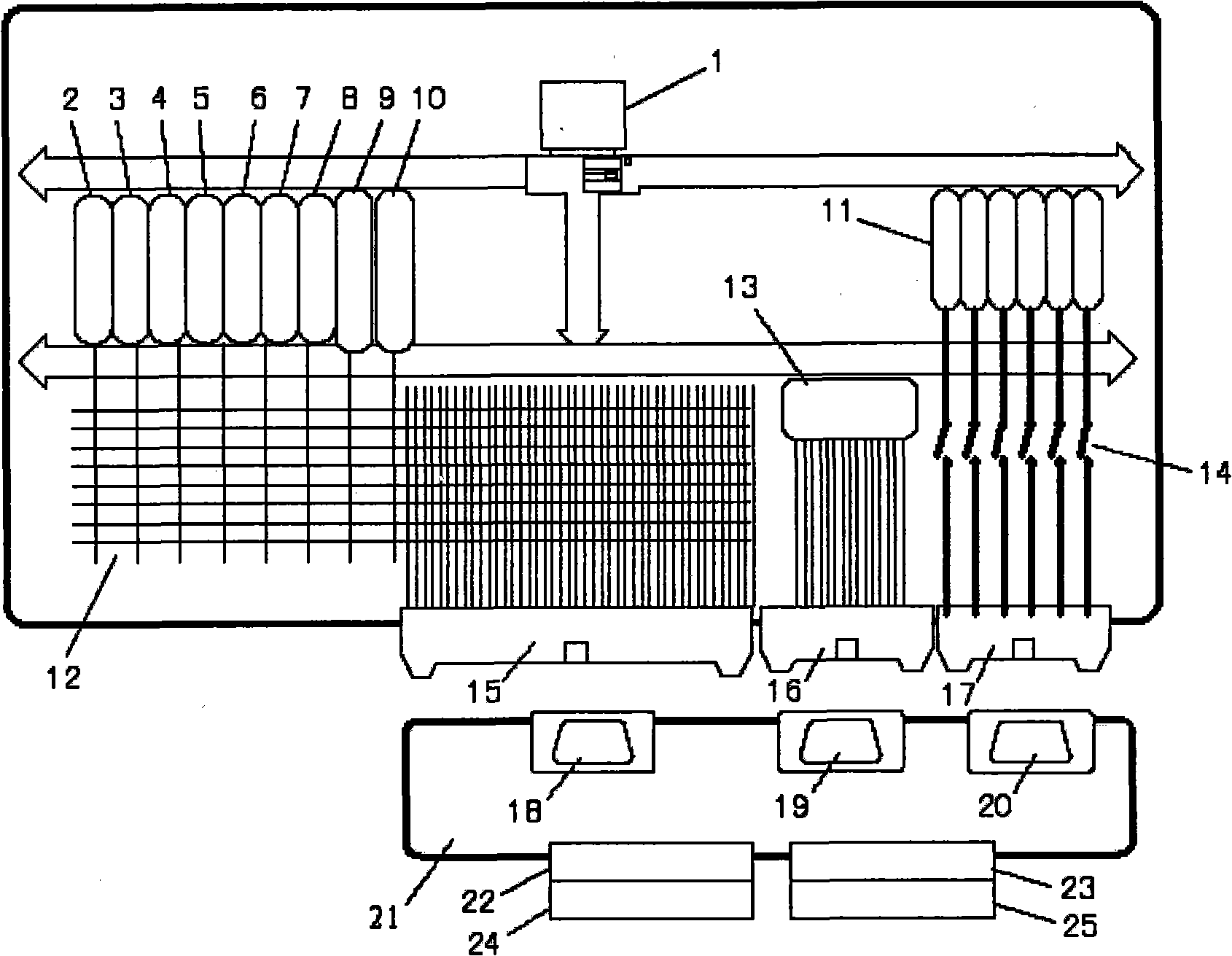

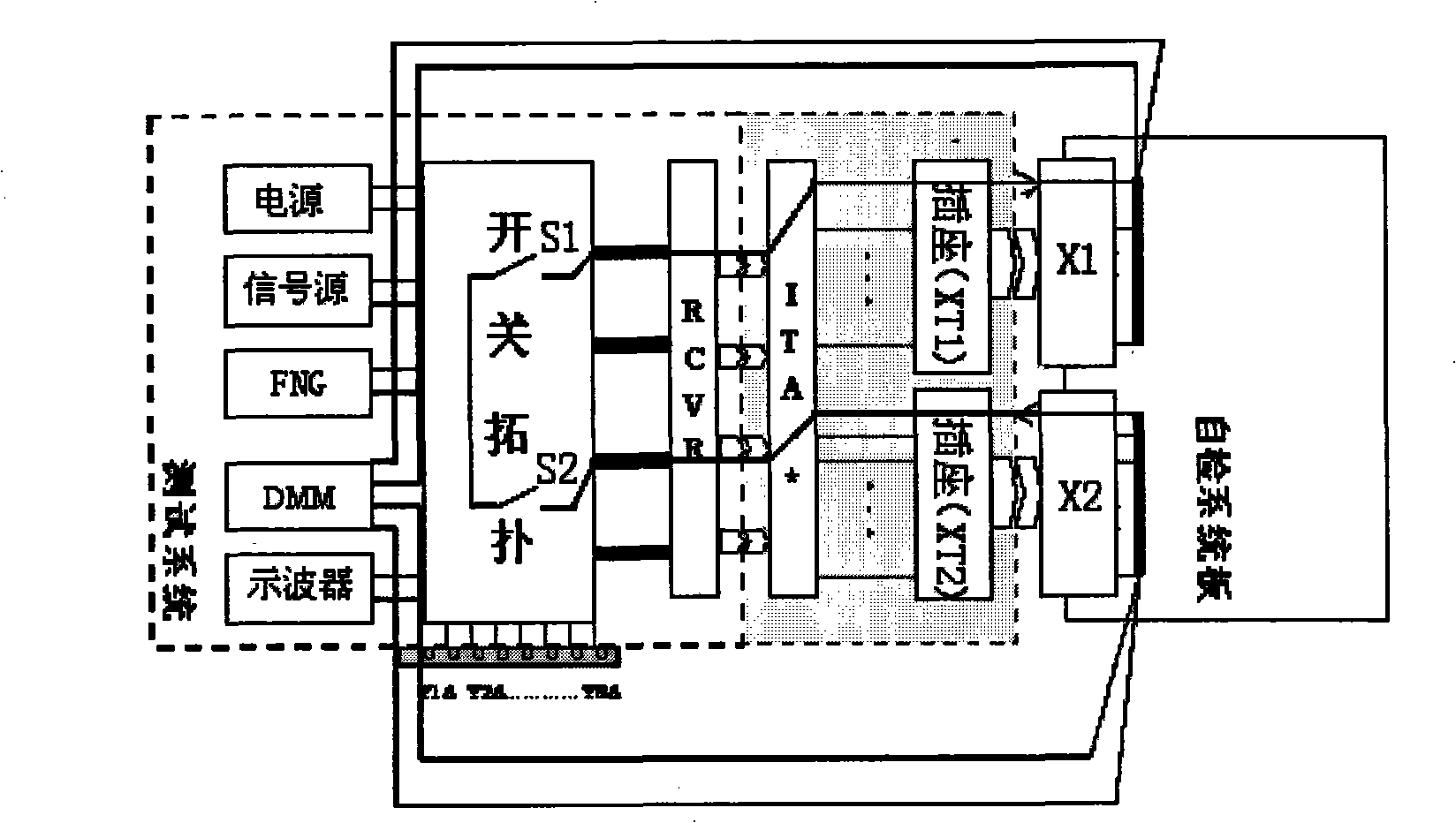

[0016] The block diagram of the whole test system is as follows: figure 1 As shown: the whole test system adopts the control mode of GPIB+PXI mixed bus, and the system includes industrial computer 1, measuring desktop instrument 2-11, PXI system 12-14 and adapter interface system 18-25. The industrial computer controls all test desktop instruments through the GPIB bus, including oscilloscope 2, multimeter 3, first signal power supply 4, second signal power supply 5, third signal power supply 6, fourth signal power supply 7, and first signal generator 8 , the second signal generator 9 , the fifth signal power source 10 , and the power supply power source 11 . The industrial computer controls all the boards in the PXI chassis through the PXI bus, including the matrix switch card 12, the digital input and output card 13 and the general switch card 14.

[0017] The oscilloscope 2 collects the waveform of the circuit board under test under the control of the industrial computer 1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com