Method and apparatus for removing SO3 from flue gas

A flue gas, ammonia gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high process cost and uneconomical, increase the cost of large equipment, and reduce engineering costs and maintenance costs. The effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

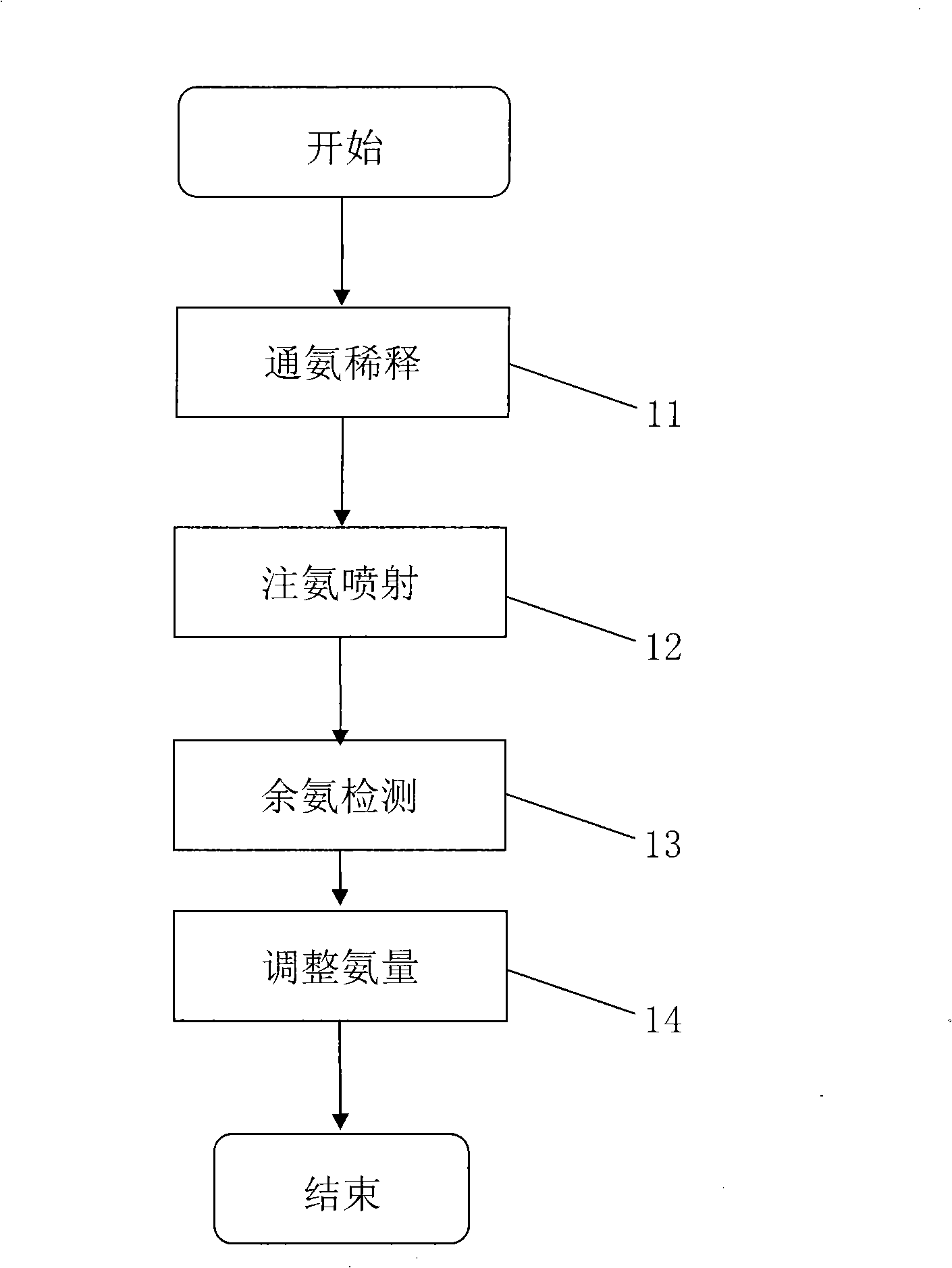

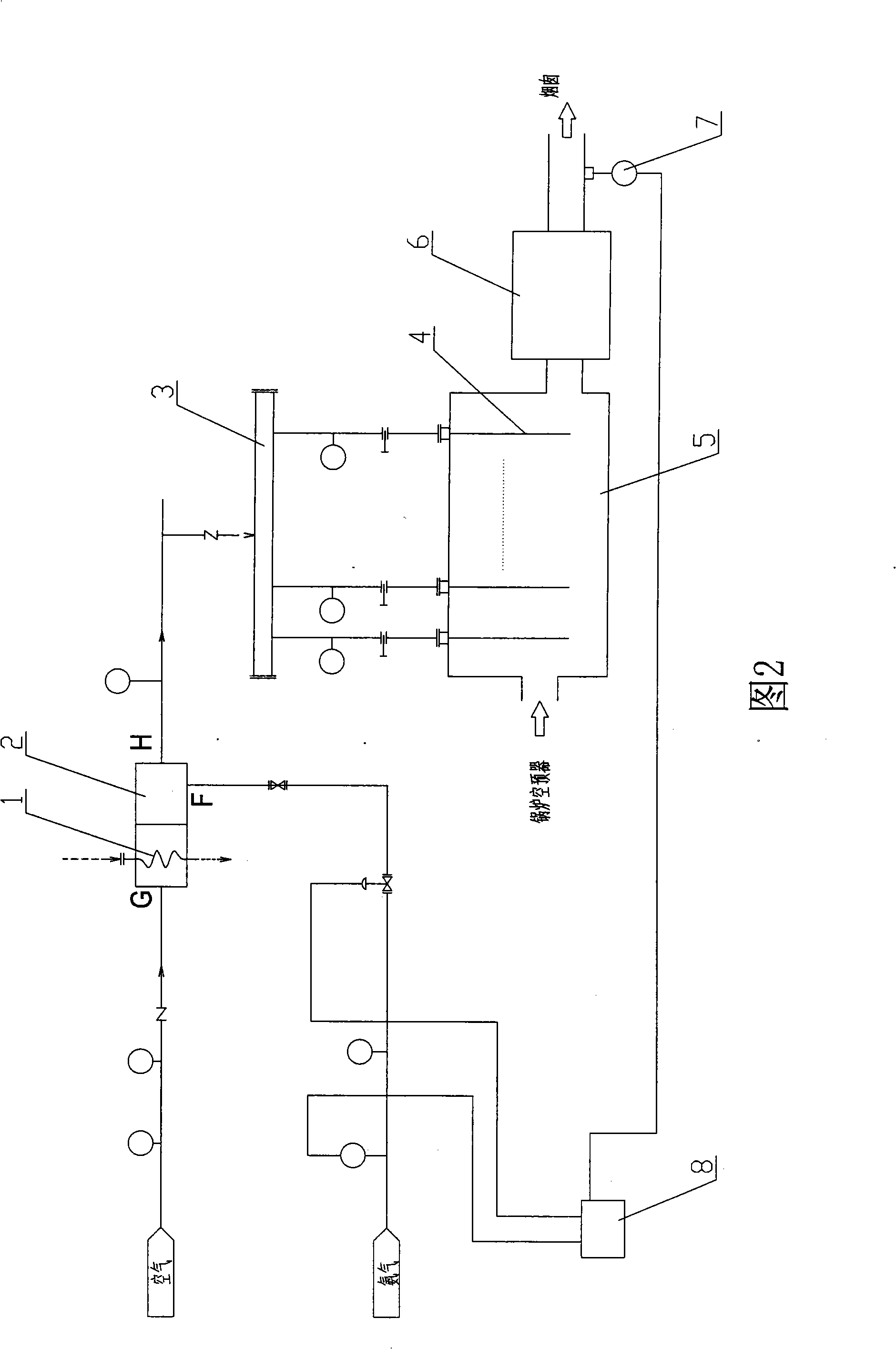

[0025] refer to figure 1 , a SO removal from flue gas 3 method, including the following steps:

[0026] Ammonia dilution 11: The air is boosted by the blower, heated by the air heater and flows into the mixer. The ammonia gas evaporated from the liquid ammonia is metered into the mixer. In the mixer, ammonia is mixed and diluted with hot air, and the explosion of ammonia gas is controlled. Within the limit; the mixer used is a co-directional and downstream mixing structure, and is equipped with a turbulent baffle.

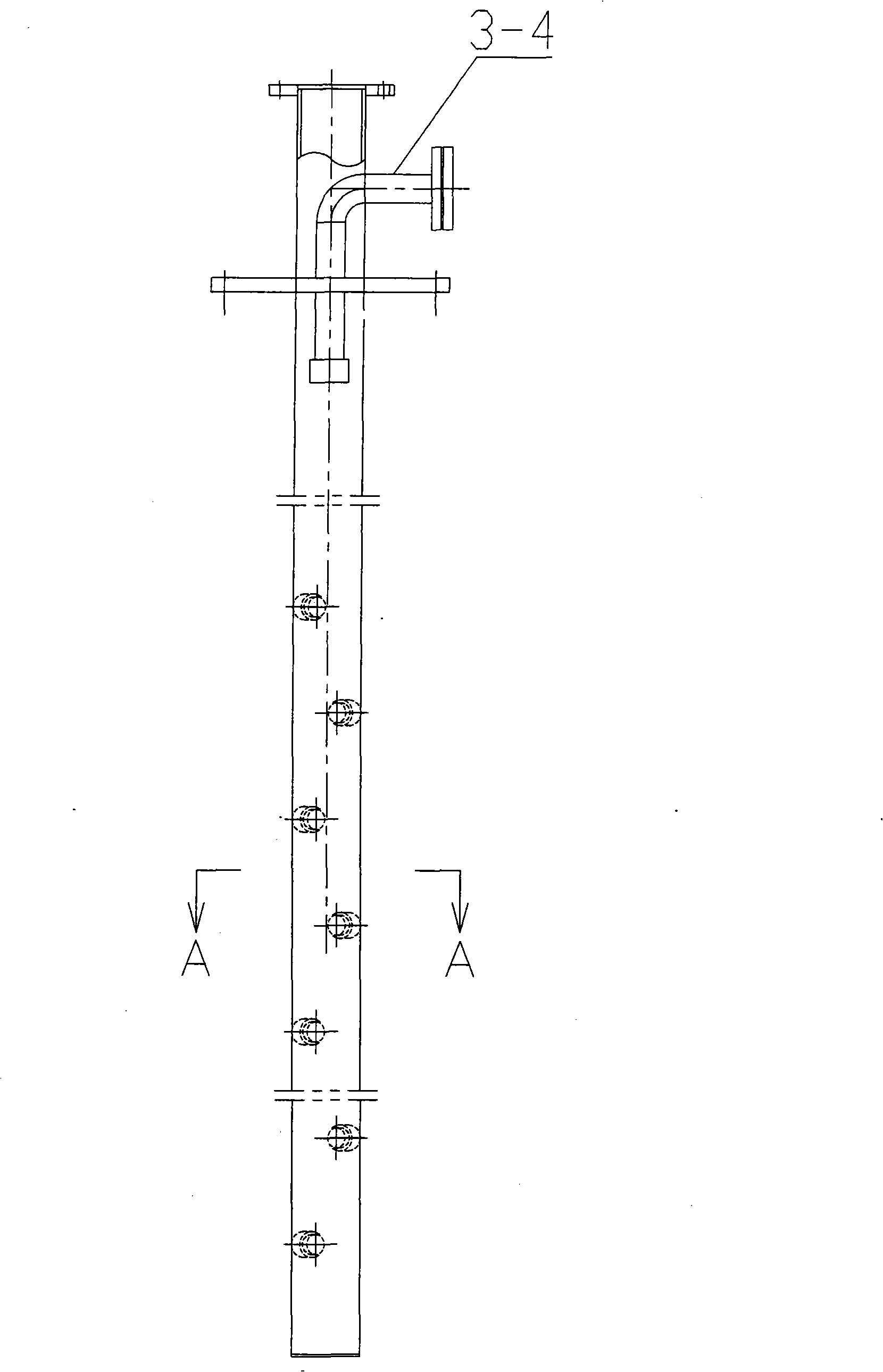

[0027] Ammonia injection injection 12: The mixed and diluted uniform ammonia gas is evenly injected into the flue through the ammonia injection injection system, and mixed with the flue gas, ammonia and SO in the flue gas 3 Reaction to remove SO 3 , remove SO 3 The final flue gas enters the flue gas system equipment; the ammonia injection injection system consists of an ammonia injection distribution main pipe and multiple nozzle pipes installed side by side. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com