Numerical control bending machine and bending method thereof

A technology of bending machine and numerical control device, applied in the direction of digital control, mechanical equipment, electrical program control, etc., can solve the problems of low work efficiency, failure to improve work efficiency, waste, etc., achieve simple processing, improve work efficiency and processing quality, and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

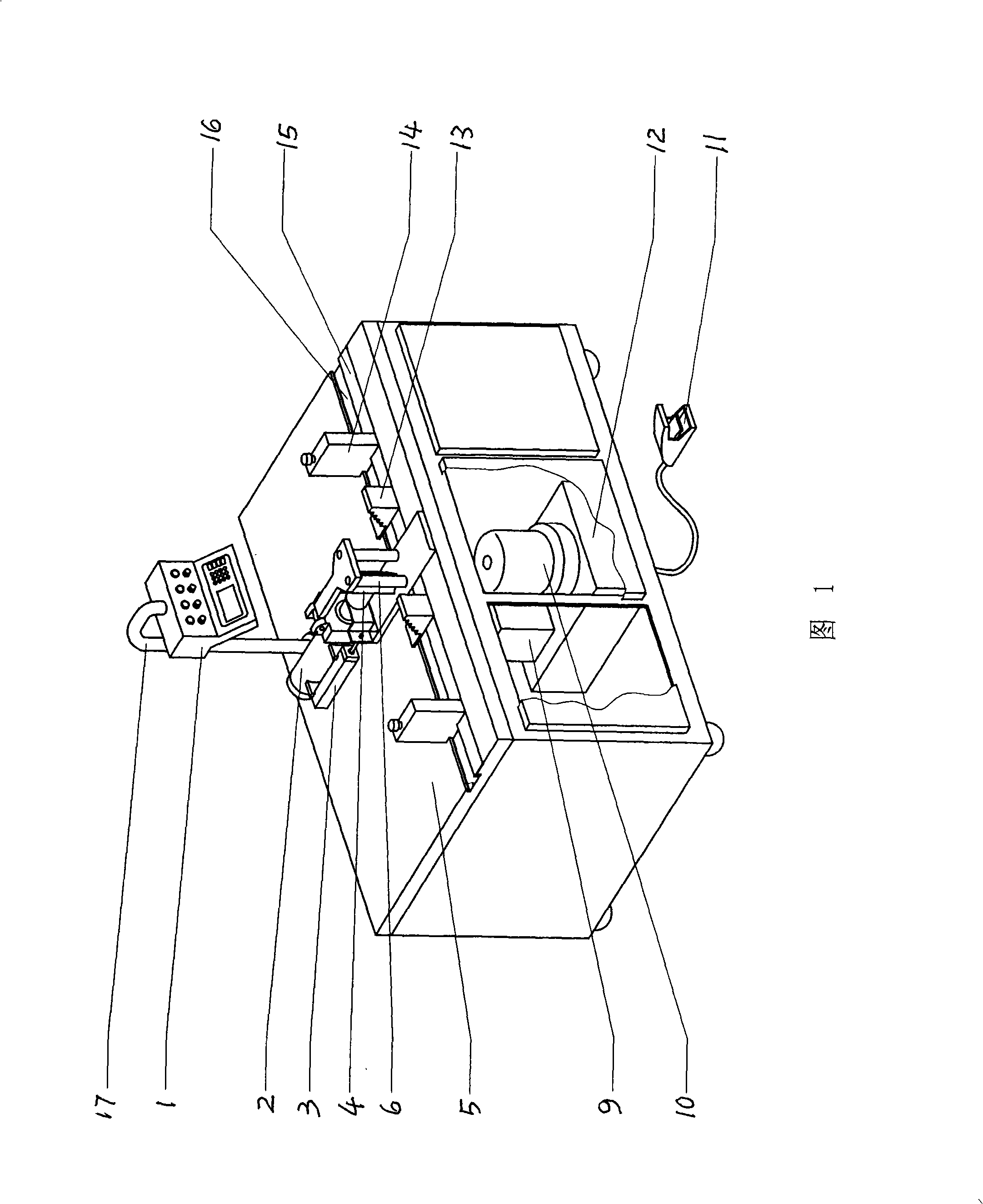

[0031] The present invention is further explained as follows with reference to accompanying drawing in conjunction with specific embodiment:

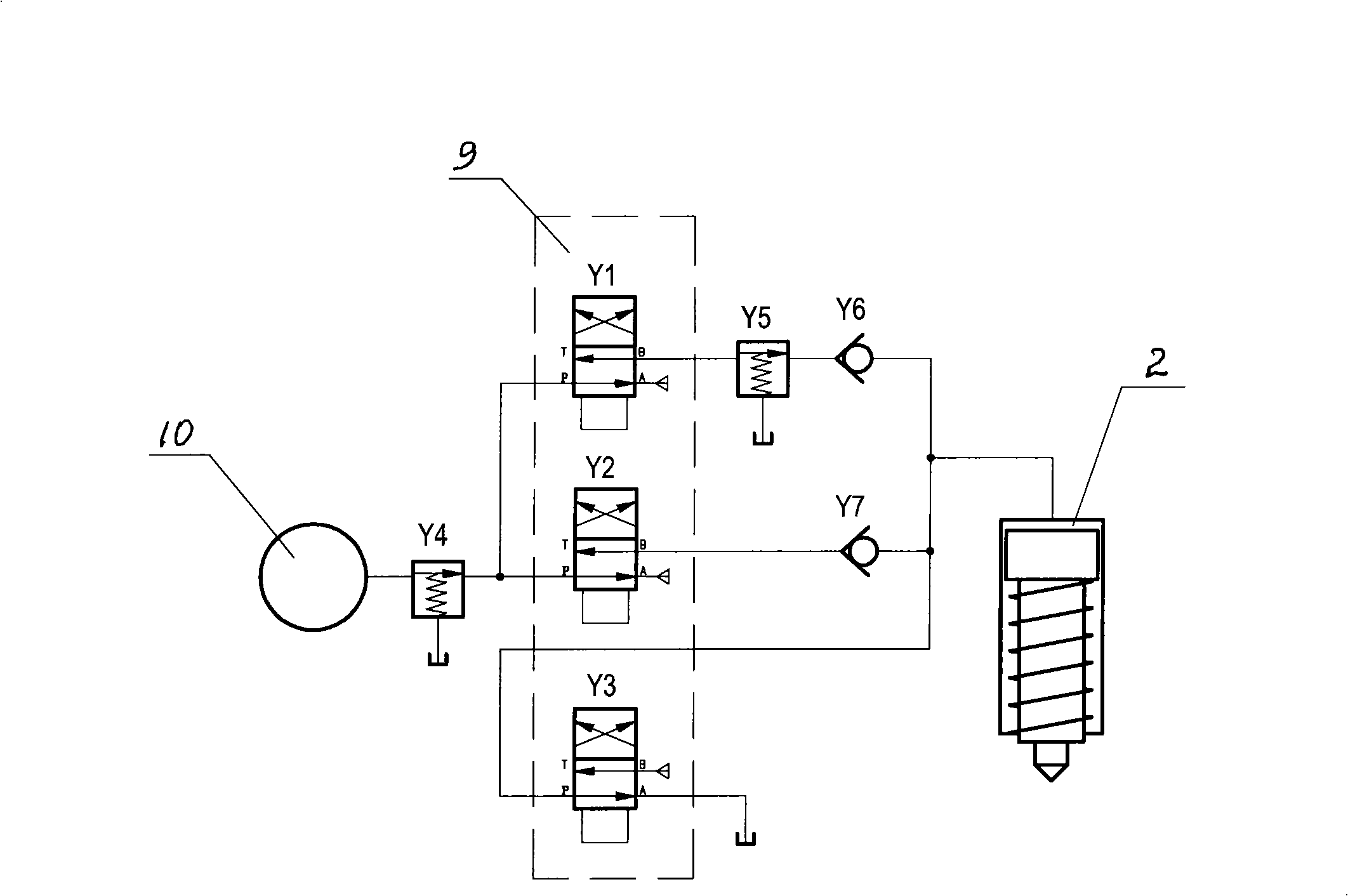

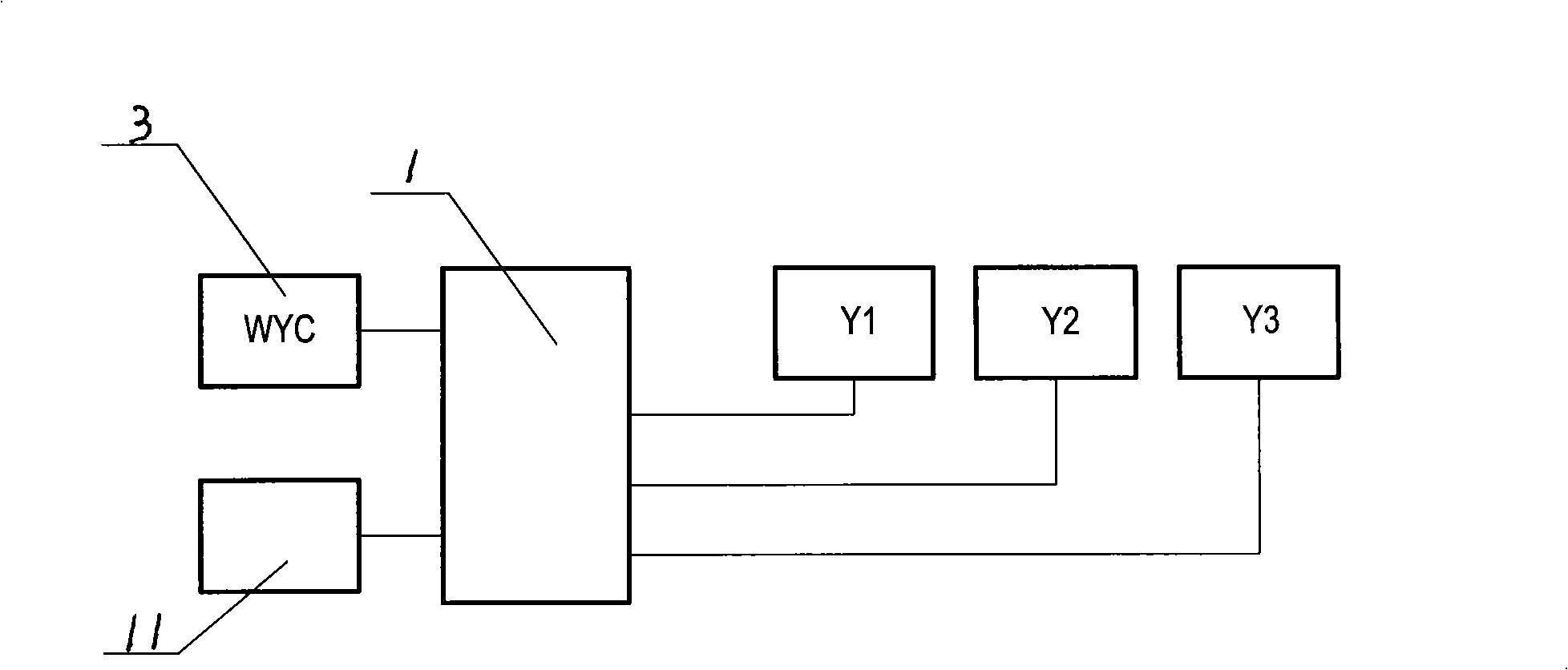

[0032] A numerically controlled bending machine, whose structure is shown in the attached drawing 1, is mainly composed of a frame platen 5, a pressing head 4, a positioning guide column 6, a numerically controlled device 1 and a hydraulic transmission device. The top pressure head 4 and two positioning guide columns 6 are installed on the frame platen 5, the top pressure head 4 is connected with the oil cylinder 2, and the oil pump 10 is installed under the frame platen 5, and the oil pump 10 passes through the solenoid valve group 9 and the pressure limiting valve Y4, Y5, one-way valves Y6, Y7 and oil tank I2 are connected by oil pipe and oil cylinder 2 to form a hydraulic transmission device. The solenoid valve group 9 includes three solenoid valves Y1, Y2, Y3, and the hydraulic transmission device is electrically connected with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap