Moisture-keeping finishing method for natural colored cotton knit goods

A knitwear and wet finishing technology, applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve the problems of hygroscopicity, poor water absorption, poor moisture retention, etc., and achieve easy manipulation, stable performance of colored cotton, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Colored cotton jersey, soak in warm water at 60-70°C for 10 minutes, add 2.0 g / L enzyme (pectinase: cellulase mass ratio 70:30), control the bath ratio to 1:20, and then adjust the pH value to 6.0, The temperature is 50°C, soak for 75 minutes, raise the temperature to 85°C, keep warm for 10 minutes, and shake dry for later use.

[0022] According to 40g / L moisturizing finishing agent CBS, use acetic acid to adjust the pH to 6-7, prepare the finishing liquid, dip and pad the colored cotton jersey, one dip and one pad, the liquid retention rate is 100%, dry at 100°C, and bake at 150°C Bake for 45 seconds.

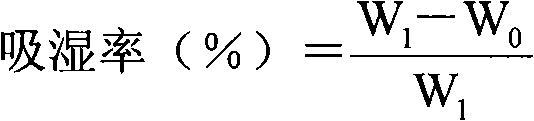

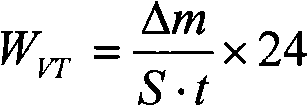

[0023] After moisturizing finishing, the moisturizing performance of colored cotton is evaluated by moisture absorption rate and moisture permeability:

[0024] (1) Moisture absorption rate. Dry the colored cotton fabric to a constant weight, weigh it (accurate to 0.0001g), place it in a constant temperature and humidity box for 24 hours at a constant temperature of ...

Embodiment 2

[0037] For colored cotton ribs, soak in warm water at 60-70°C for 10 minutes, add 2.0g / L enzyme (pectinase: cellulase mass ratio 70:30), control the bath ratio to 1:20, then adjust the pH value to 6.0, the temperature Soak at 50°C for 75 minutes, heat up to 85°C, keep warm for 10 minutes, and shake dry for later use.

[0038] Use 5% moisturizing finishing agent CBS, adjust the pH to 6-7 with acetic acid, prepare the finishing solution, impregnate the rib of colored cotton, control the bath ratio to 1:10, soak at 50°C for 30min, then centrifugally dehydrate, and dry at 100°C.

[0039] After finishing, the moisture absorption rate of colored cotton rib increases by 100%, and the moisture permeability increases by 50%.

Embodiment 3

[0041] Colored cotton weft plain knitted fabrics, soaked in warm water at 60-70°C for 10 minutes, added 2.0 g / L enzyme (pectinase: cellulase mass ratio 70:30), controlled bath ratio to 1:20, and then adjusted the pH value = 6.0, temperature 50°C, soak for 75 minutes, raise the temperature to 85°C, keep warm for 10 minutes, and shake dry for later use.

[0042] According to 60g / L moisturizing finishing agent CBS, use acetic acid to adjust the pH to 6-7, prepare the finishing solution, pad the colored cotton knitwear, one dipping and one padding, the liquid retention rate is 80%, dry at 100°C, bake at 160°C Bake for 30 seconds.

[0043] After finishing, the moisture absorption rate of the colored cotton weft plain knitted fabric increases by 70%, and the moisture permeability increases by 45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com