Sealing apparatus, sealing method and encapsulation method of integrated circuit chip

A technology of integrated circuits and sealing devices, which is applied in the direction of circuits, electrical components, and electrical solid devices, to achieve the effects of low production costs, broad market prospects, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions of the embodiments of the present invention will be described in further detail below with reference to the drawings and embodiments.

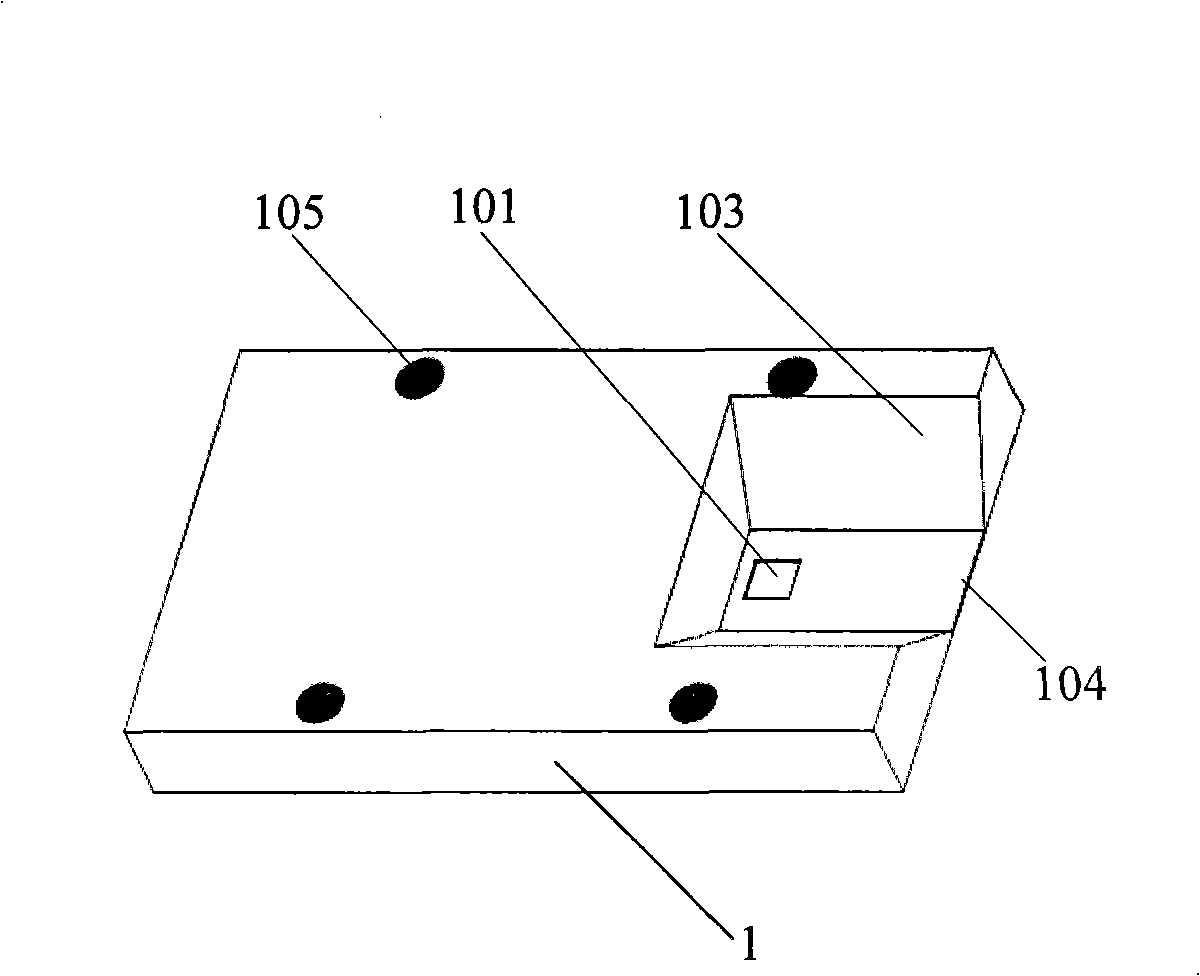

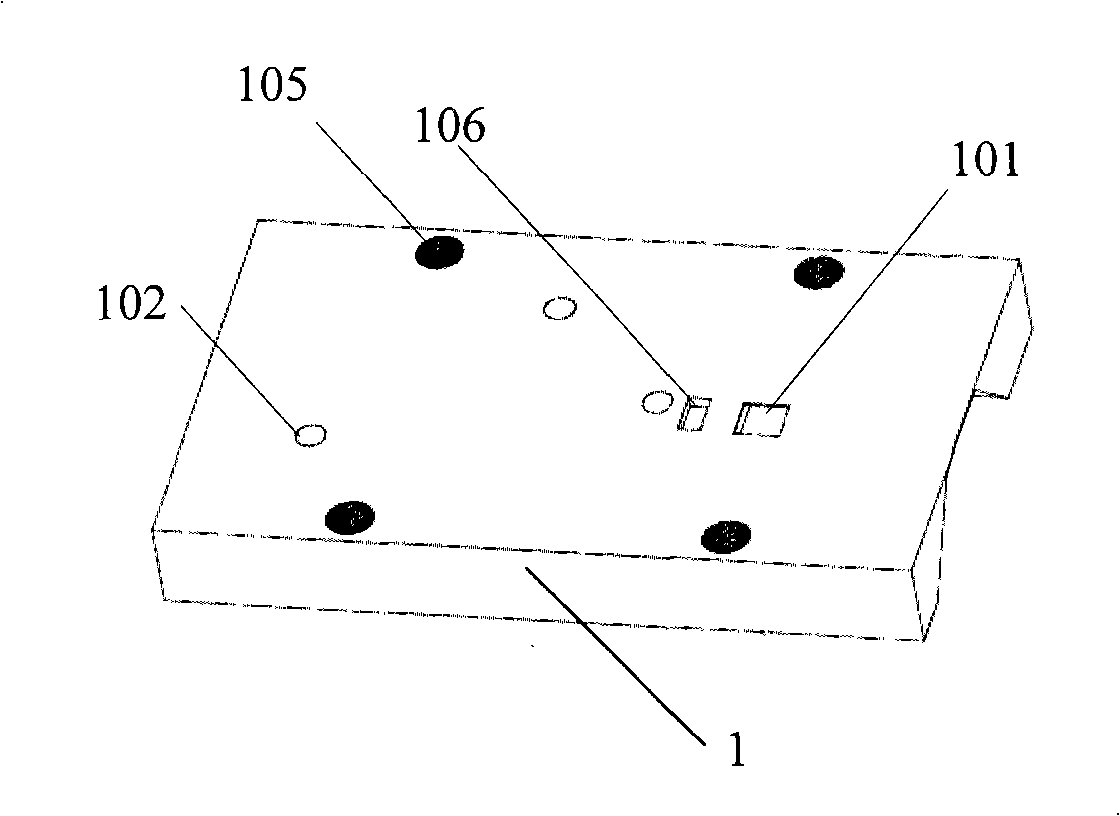

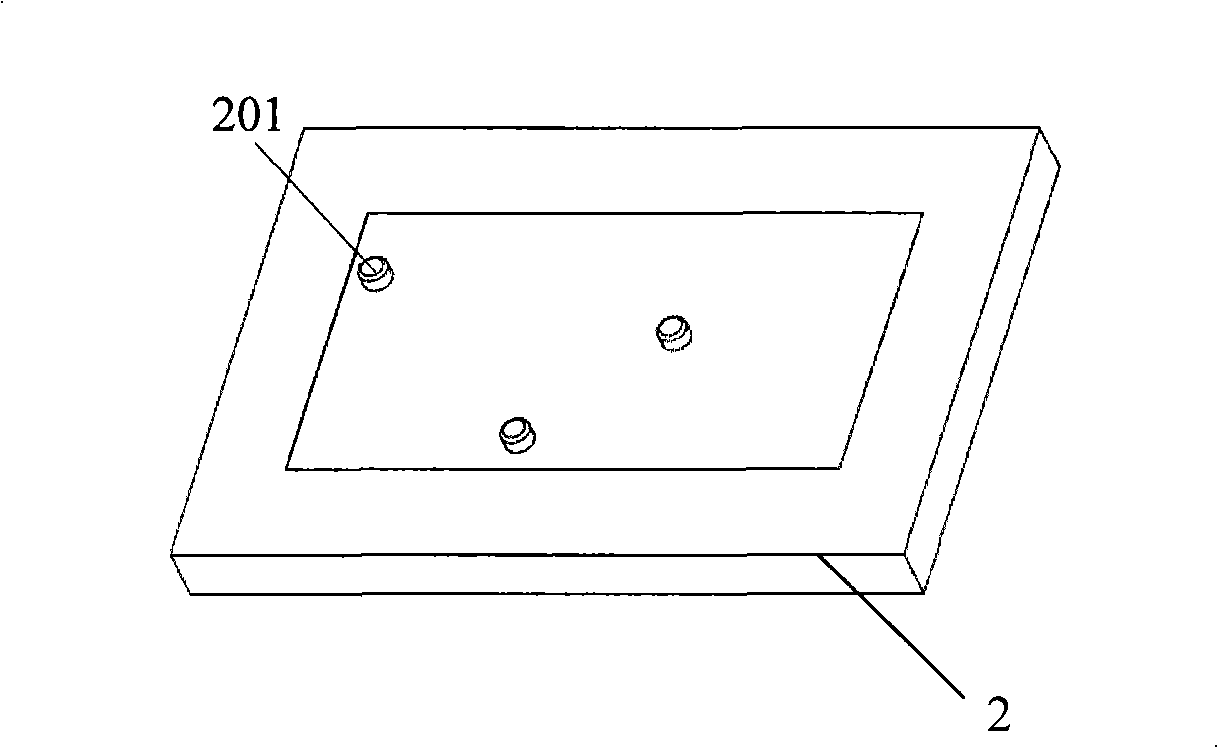

[0057] The present invention provides a kind of sealing glue device of integrated circuit chip, to guarantee the shape and the thickness of the encapsulation epoxy resin on the surface of IC chip, the glue sealing device of the present invention comprises figure 1 and 2 the top plate 1 shown; and image 3 The bottom plate 2 shown is used to support a circuit board with integrated circuit chips. The top plate 1 is fastened with the bottom plate 2, so that the circuit board and the bottom surface of the top plate are closely attached, and the top plate has at least one window corresponding to the position of the integrated circuit chip on the circuit board, so that the chip is completely exposed Come out to pour the sealant.

[0058] Such as figure 1 As shown, it is a schematic diagram of the top surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com