Leadframe and flip chip type semiconductor package using leadframe as chip supporter

A lead frame and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve the problems affecting the reliability of semiconductor packages 2, delamination of ground plane 221 and packaging colloid 23, large thermal stress, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0067] refer to Figure 3A and Figure 3B As shown, it is the top view and the edge view of the flip-chip semiconductor package according to the first embodiment of the present invention. Figure 3A A sectional view taken along line 3B-3B is shown.

[0068] As shown in the figure, the semiconductor package 3 is composed of a chip 31, a lead frame 32 for carrying the chip 31, a plurality of solder bumps 30a and ground bumps 30b for electrically connecting the chip 31 to the lead frame 32, And the encapsulant 33 for covering the chip 31 , part of the lead frame 32 , and the solder bump 30 a and the ground bump 30 b.

[0069] The chip 31 is mounted on the lead frame 32 in a flip-chip manner, that is, the active surface (Active Surface) 310 of the chip 31 faces the lead frame 32 and is opposite to the non-active surface (Non-Active Surface) of the active surface 310. active Surface) 311 faces away from the lead frame 32.

[0070] The lead frame 32 includes a plurality of guide...

no. 2 example

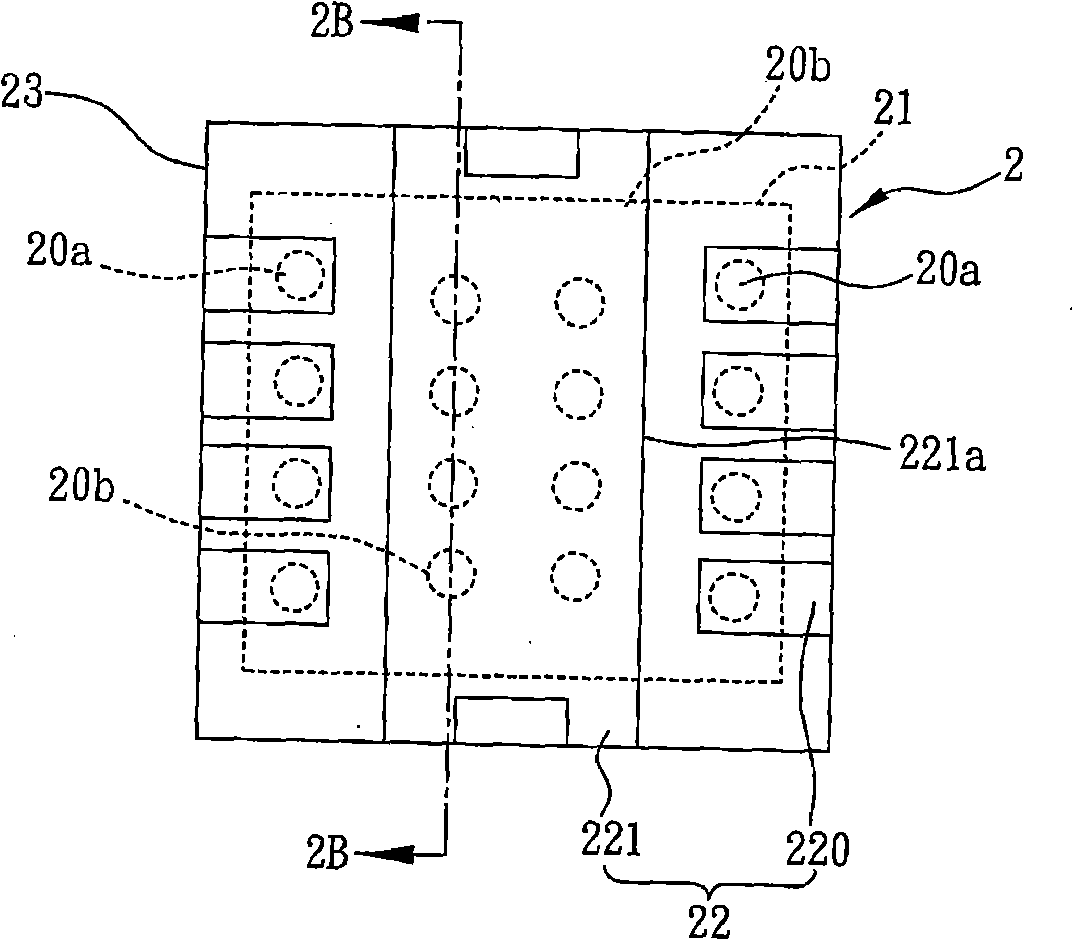

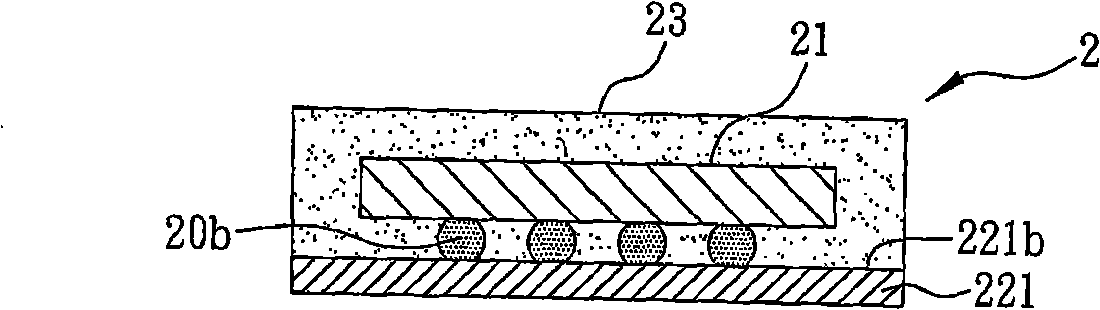

[0075] like Figure 4A and Figure 4B Shown is a top view and an edge view of a semiconductor package according to a second embodiment of the present invention Figure 4A A cross-sectional view taken along line 4B-4B.

[0076] As shown in the figure, the semiconductor package 4 of the second embodiment is substantially the same as that described in the first embodiment. , the slit 421a is non-linear, so that the formation of the zigzag slit 421a provides a bonding area between the ground plane 421 and the encapsulant 43, thereby further improving the bonding between the ground plane 421 and the encapsulant 43; And the formation position of the zigzag slit 421 a is not located in the middle of the ground plane 421 , so that the formation position of the slit is not limited.

[0077] In order to further enhance the bonding between the ground plane 421 and the encapsulation body 43, recesses 421f and 421g can be formed on both sides of the ground plane 421 along the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com