Water-soluble flocculant and preparation thereof

A flocculant and water-soluble technology, which is applied in the field of sewage treatment, can solve the problems of low suspended solids removal rate and cannot fully meet the needs of white clay sewage treatment, and achieve excellent suspended solids removal performance, low cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

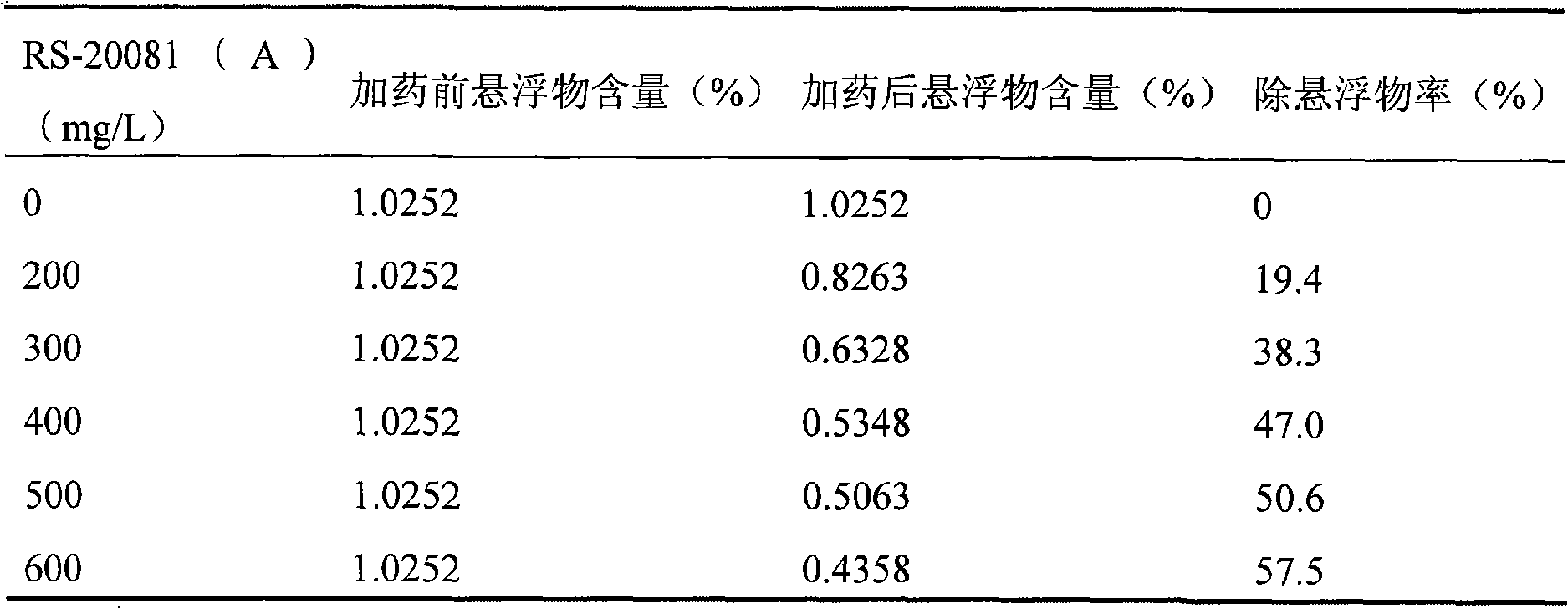

[0015] Embodiment 1, by weight 55% sodium polyacrylate (molecular weight is 9.0 * 10 6 ) and 45% polyacrylamide (molecular weight 2.0×10 6 ) directly mixed uniformly by means of mechanical blending to obtain flocculant RS-20081(A) of the present invention. See Table 1 for the experiment of flocculant RS-20081(A) to remove suspended solids.

[0016] Table-1 Flocculant test

[0017]

[0018]

[0019] It can be seen from Table 1 that the flocculant RS-20081(A) has a high removal rate of suspended solids in the concentration range of 900-1200mg / L, and the removal rate of suspended solids is above 89.0%, which can meet the requirements of the catalyst. The sewage treatment needs of the plant, and the sewage discharge meets the standard.

Embodiment 2

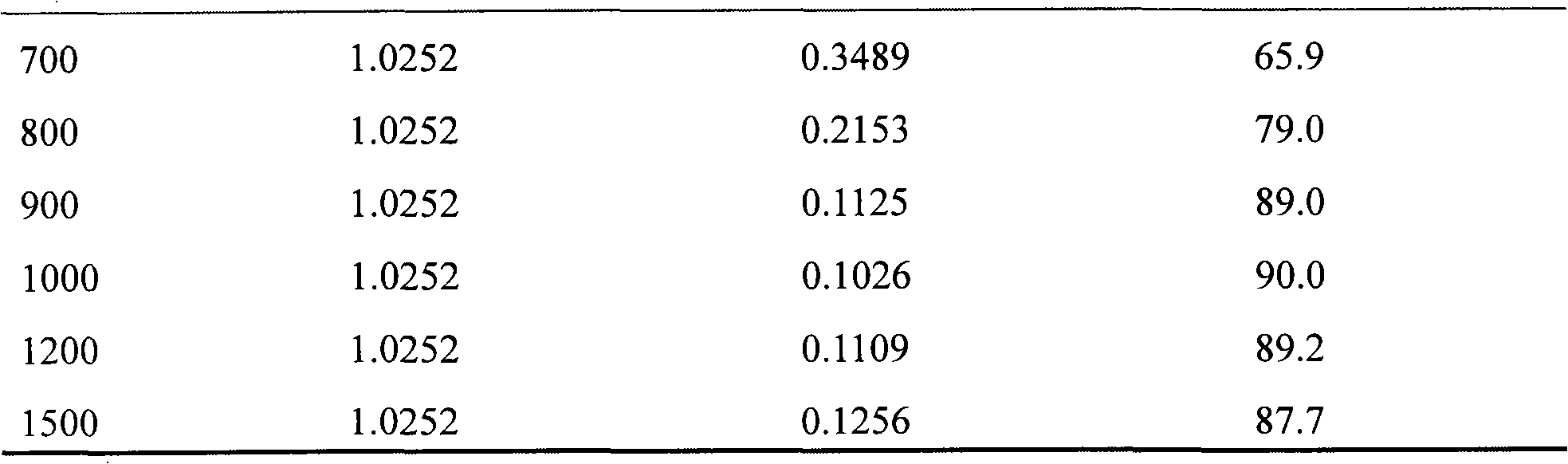

[0020] Embodiment 2, the sodium polyacrylate (molecular weight is 10.0 * 10 6 ), 48% polyacrylamide (molecular weight 3.0×10 6 ) directly mixed uniformly by means of mechanical blending to obtain flocculant RS-20081(B) of the present invention. See Table 2 for the experiment of flocculant RS-20081(B) to remove suspended solids.

[0021] Table-2 Flocculant test

[0022]

[0023] It can be seen from Table 2 that the flocculant RS-20081(B) exhibited a high removal rate of suspended solids in the concentration range of 900-1200 mg / L, and the removal rates of suspended solids were above 89%, which can meet the requirements of the catalyst. The sewage treatment needs of the plant, and the sewage discharge meets the standard.

Embodiment 3

[0024] Embodiment 3, by weight 50% sodium polyacrylate (molecular weight is 11.0 * 10 6 ), 50% polyacrylamide (molecular weight 5.0×10 6 ) directly mixed uniformly by means of mechanical blending to obtain flocculant RS-20081(C) of the present invention. See Table 3 for the experiment of flocculant RS-20081(C) to remove suspended solids.

[0025] Table-3 Flocculant test

[0026]

[0027] It can be seen from Table 3 that the flocculant RS-20081(C) exhibits a high removal rate of suspended solids in the concentration range of 900-1200mg / L, and the removal rate of suspended solids is above 88.3%, which can meet the requirements of the catalyst. The sewage treatment needs of the plant, and the sewage discharge meets the standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com