Method and device for applying plane material pieces and embroidery machine

An embroidery machine and embroidery technology, applied in the field of embroidery machines, can solve the problems of high cutting temperature, damage to material layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

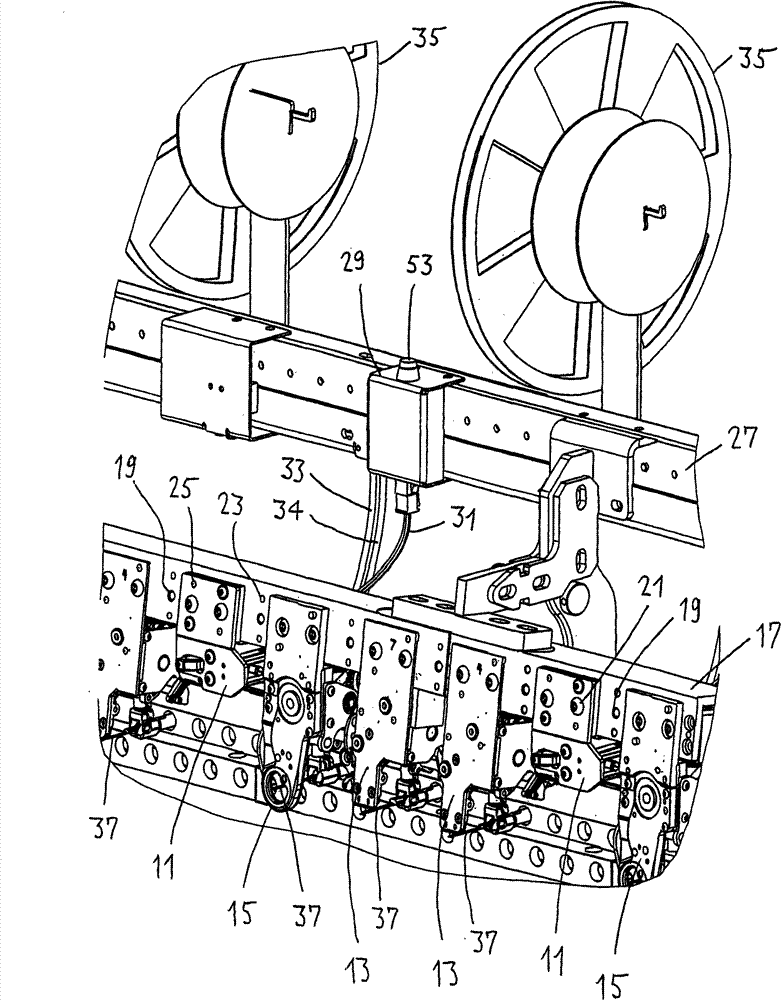

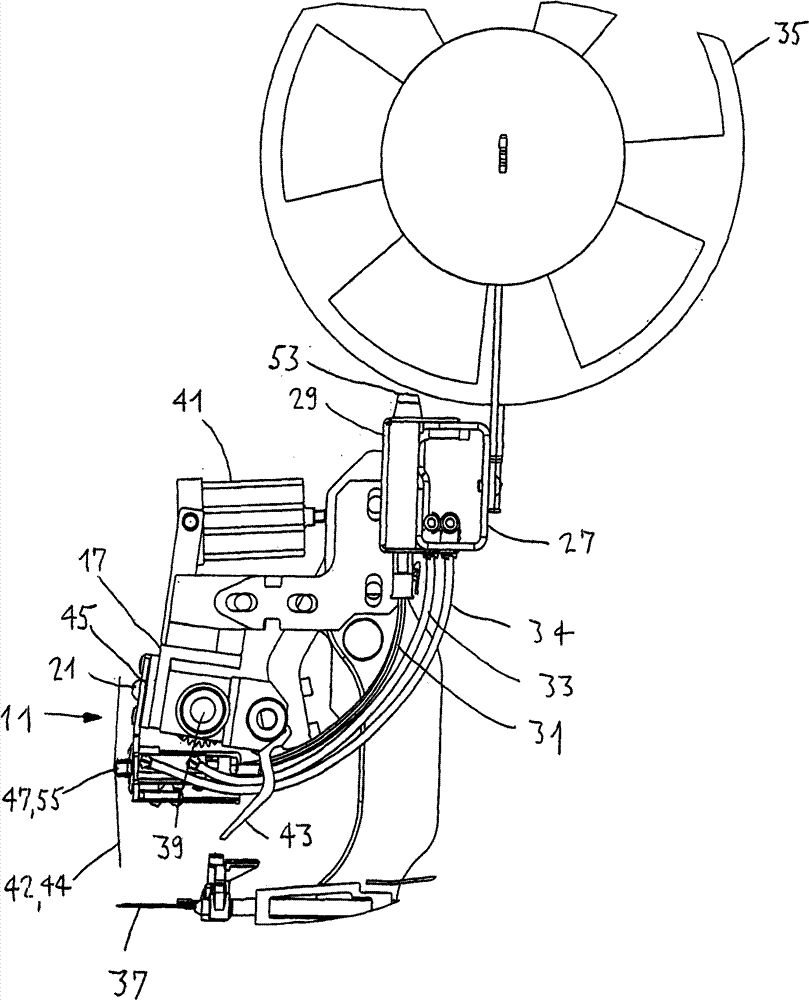

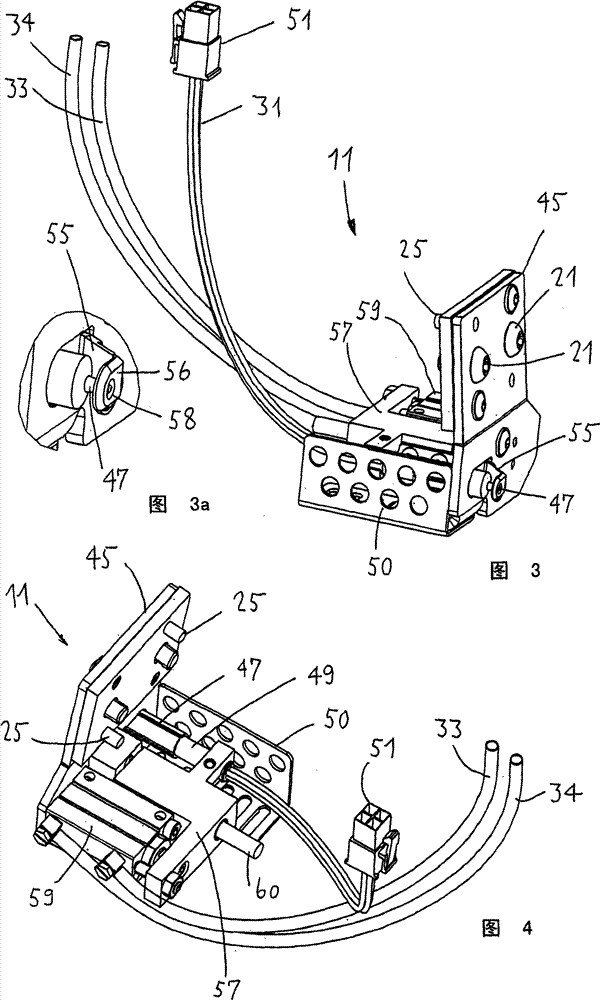

[0032] figure 1Two intarsia embroidery heads 11 are shown together with a patch head 13 and a braided thread head 15 . The trim head 13 is designed like the above-mentioned EP-A-1 764 434, and the braid head 15 is likewise designed like the above-mentioned EP-A-1 764 435. All these intarsia embroidery heads 11, patch heads 13 and braiding heads 15 are fastened easily replaceable on a frame 17 of the rust machine, which frame also has threaded holes 19 for bolts 21 for this purpose and also has holes for The guide hole 23 of the guide pin 25. This enables precise positioning of the intarsia embroidery head 11 , the patch head 13 and the braided thread head 15 . The track 27 also extends the length of the machine. The power supply of the intarsia embroidery head 11 takes place in this track. A power cord 31 and pneumatic hoses 33 , 34 extend from the junction box and fuse box 29 to the intarsia embroidery head 11 . The bobbin for the veneer tape is marked with 35. The embr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com