A high-efficiency energy-saving anti-icing gate applied to channels

A high-efficiency, energy-saving, gate technology, used in artificial waterways, open-air water surface cleaning, construction, etc., can solve problems such as energy waste and low ice melting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

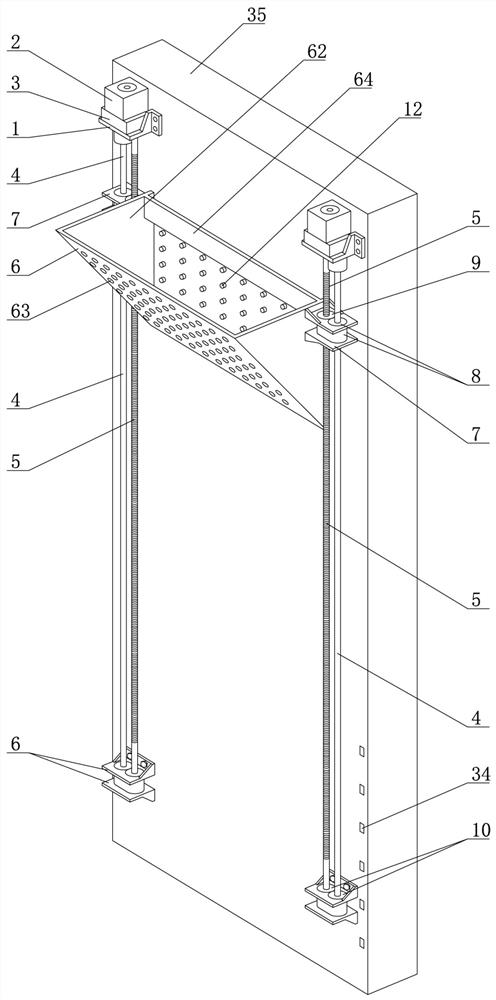

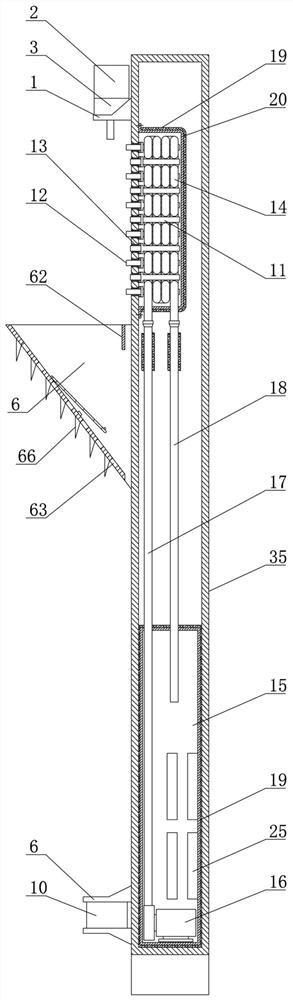

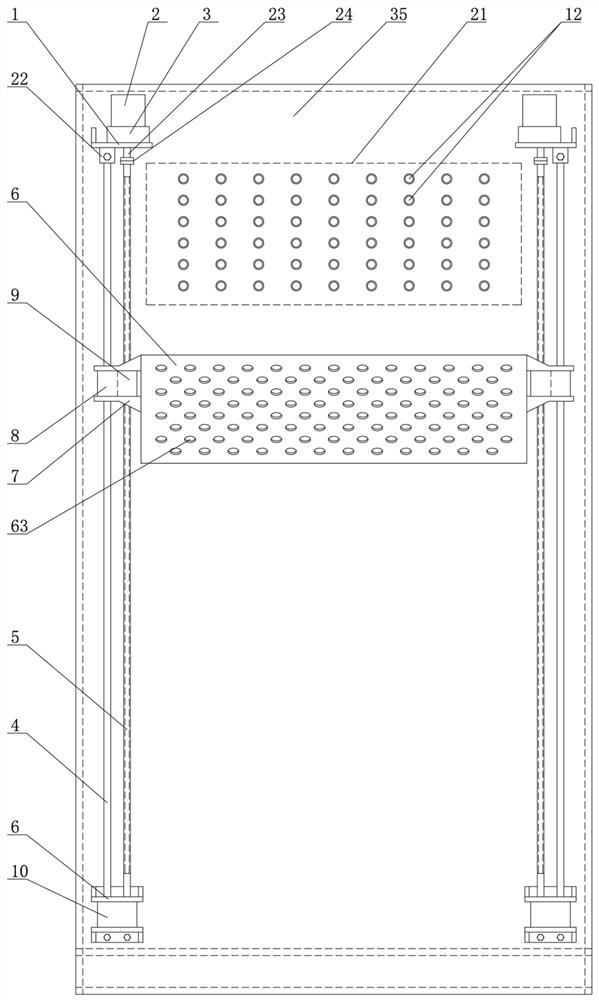

[0023] Embodiment 1: a kind of as figure 1 The anti-icing gate shown in the figure is mainly used in the transformation of the channel gate, which can efficiently and energy-savingly eliminate the ice in front of the gate and protect the safety of the gate.

[0024] From figure 1 It can be seen that a lifting bucket is provided on the side facing the water of the main body 35 of the gate. The tapered lifting bucket 6 in the figure is preferably used, and other shapes such as rectangular or body-shaped lifting bucket structures can also be used. The outer wall of the tapered lifting bucket 6 is an inclined plate 61, the two side walls 62 are vertically connected to the inclined plate 61, the inner sides of the two side walls 62 are fixedly connected by a beam 64, the beam is not in contact with the surface of the gate but there is a matching gap, Thereby, the two side walls 62 of the hoist bucket can be in contact with the ram while the crossbeam is not in contact with the ram...

Embodiment 2

[0033] Embodiment 2: Another anti-icing gate, the content is basically the same as that of Embodiment 1, the difference is the change of the lifting mechanism. The hoisting mechanism that adopts in this implementation is that lifting motor 2 is installed at the top center position of gate, and the rotating shaft of lifting motor 2 is equipped with sheave, and the end of the traction rope wound on the sheave is fixed on the lug of lifting bucket upper center.

Embodiment 3

[0034] Embodiment 3: in the anti-icing gate further improved when embodiment 2 is based on, as Figure 5 As shown, the gravity sensing mechanism adopted is to install a tension sensor between the lifting lug and the traction rope at the upper center of the lifting bucket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com