Internal combustion engine and combustion method of the same

An internal combustion engine and combustion chamber technology, applied to internal combustion piston engines, combustion engines, adding non-fuel substances to fuel, etc., can solve the inherent problem of premixed compression ignition and cannot suppress combustion noise and other problems, achieve reliable combustion, and promote the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

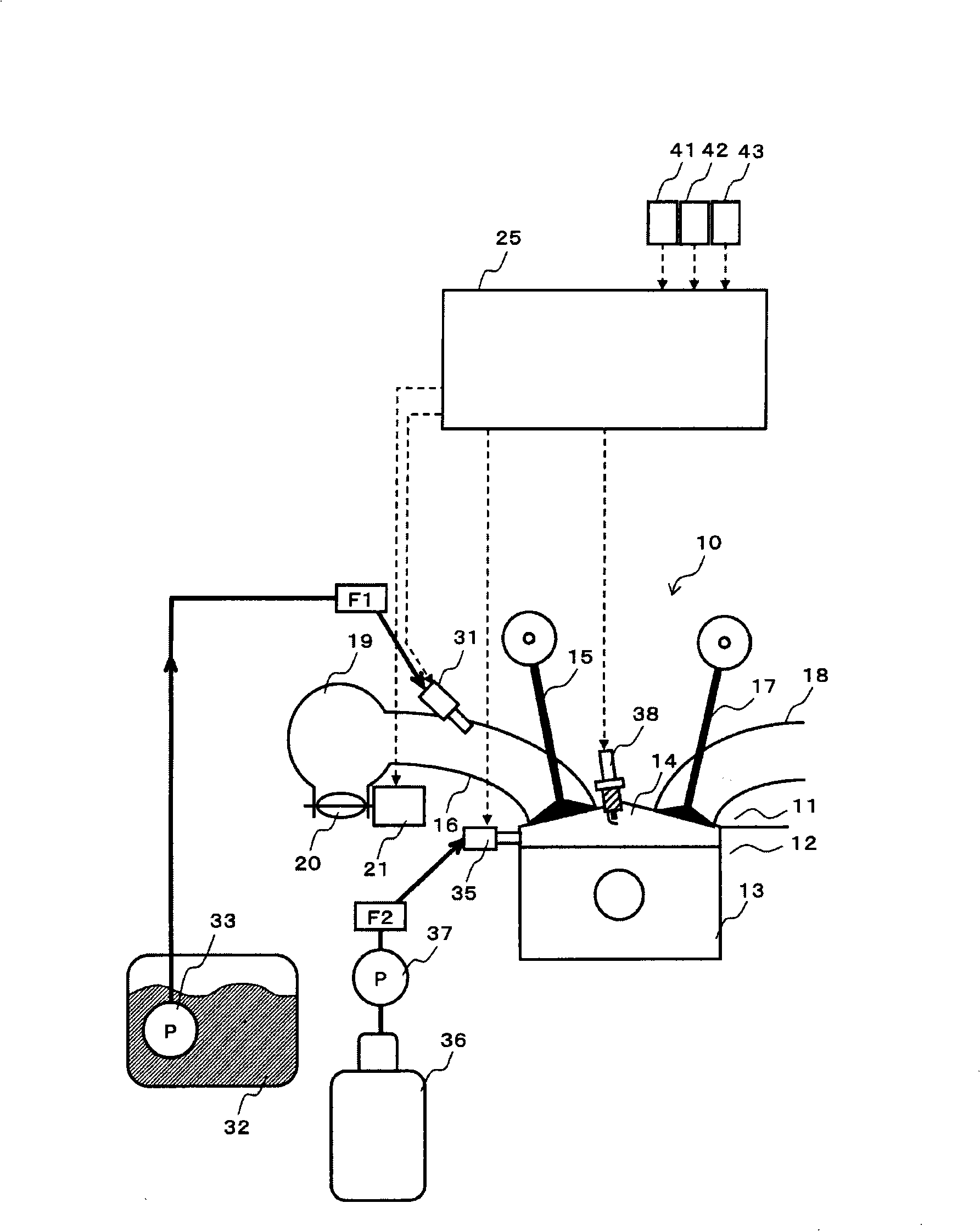

[0022] figure 1 It is a configuration diagram of an engine (internal combustion engine) according to the first embodiment of the present invention.

[0023] In engine 10 , combustion chamber 14 is formed by cylinder head 11 , cylinder block 12 , and piston 13 .

[0024] Combustion chamber 14 can supply intake air from intake port 16 , which is an intake passage, through intake valve 15 , and can discharge exhaust gas to exhaust port 18 , which is an exhaust passage, via exhaust valve 17 . In addition, a manifold portion (intake manifold) 19 is provided in the middle of the intake passage. In the intake passage, a throttle valve 20 is also provided upstream of the manifold portion 19 . The operating shaft of the throttle valve 20 is connected to the output shaft of a stepping motor 21 , and the output shaft of the stepping motor 21 rotates according to a command signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com