Method for accomplishing light beam uniformization and optical device

An optical device and homogenization technology, applied in the field of optics, can solve problems such as error, high manufacturing cost and difficulty of optical system, complicated optical device debugging process, etc., to achieve the effect of saving use cost and manufacturing cost, and avoiding complicated debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

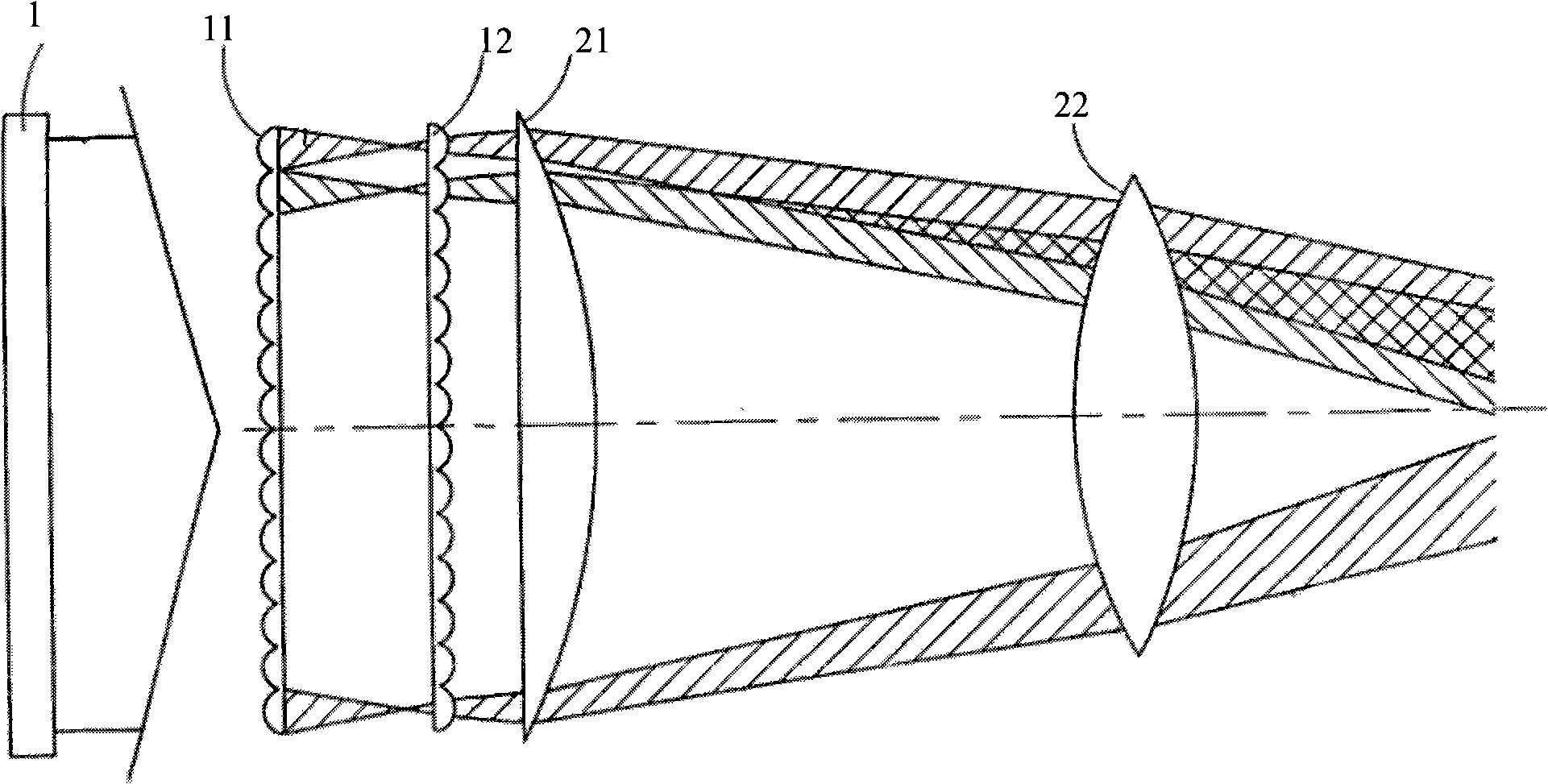

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

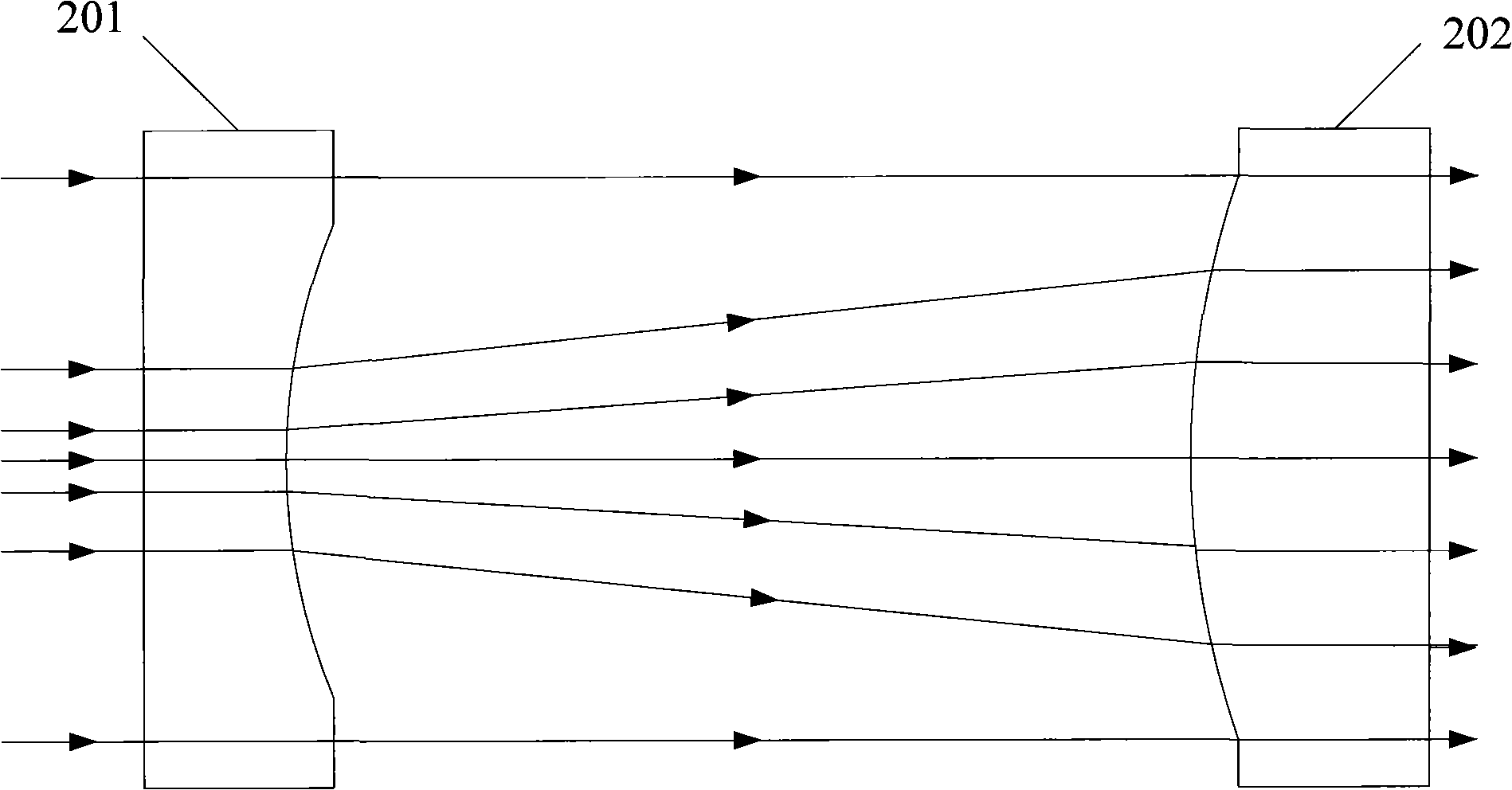

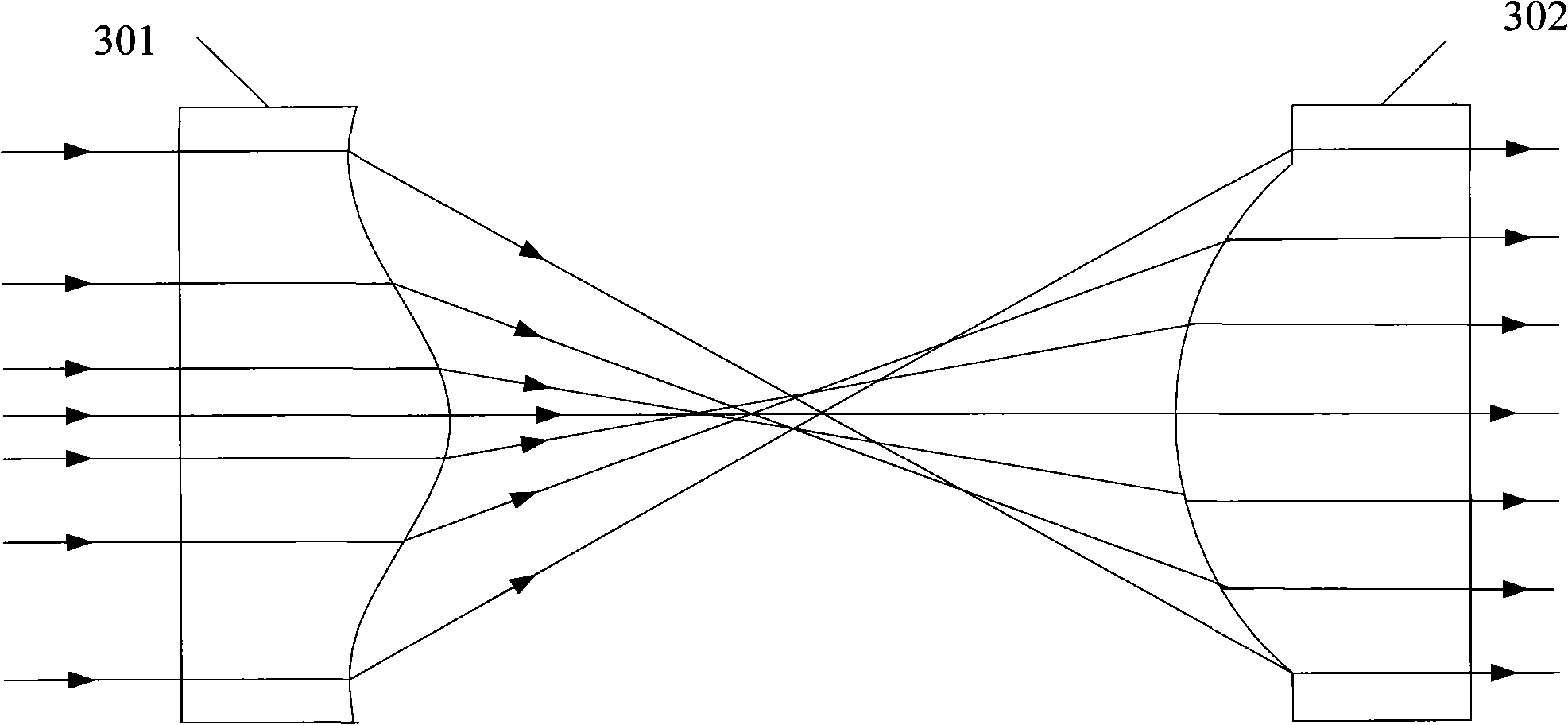

[0021] See Figure 4 , Figure 4 It is a schematic flowchart of a method for realizing beam homogenization according to an embodiment of the present invention. The optical device in the embodiment of the present invention is a double aspherical lens, and the non-uniform light beam adopted is a Gaussian light beam. Since other non-uniform light beams that can be expressed by formulas are only different from the Gaussian light beam in light distribution, the principle is the same. So no more details. Such as figure 2 As shown, the method includes:

[0022] Step S101, the first aspheric surface of the optical device receives the input laser Gaussian beam and then diverges or focuses the beam. The two aspheric surfaces of a double aspheric len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com