Compact type core construction

A compact, iron-core technology, applied in the field of iron-core structure, can solve the problems of increased production cost, small DC excitation ampere-turn, difficult insulation, etc., and achieves the effect of strengthening excitation degree, reasonable iron core structure, and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments and specific implementation methods of the present invention will be described in detail below in conjunction with the accompanying drawings.

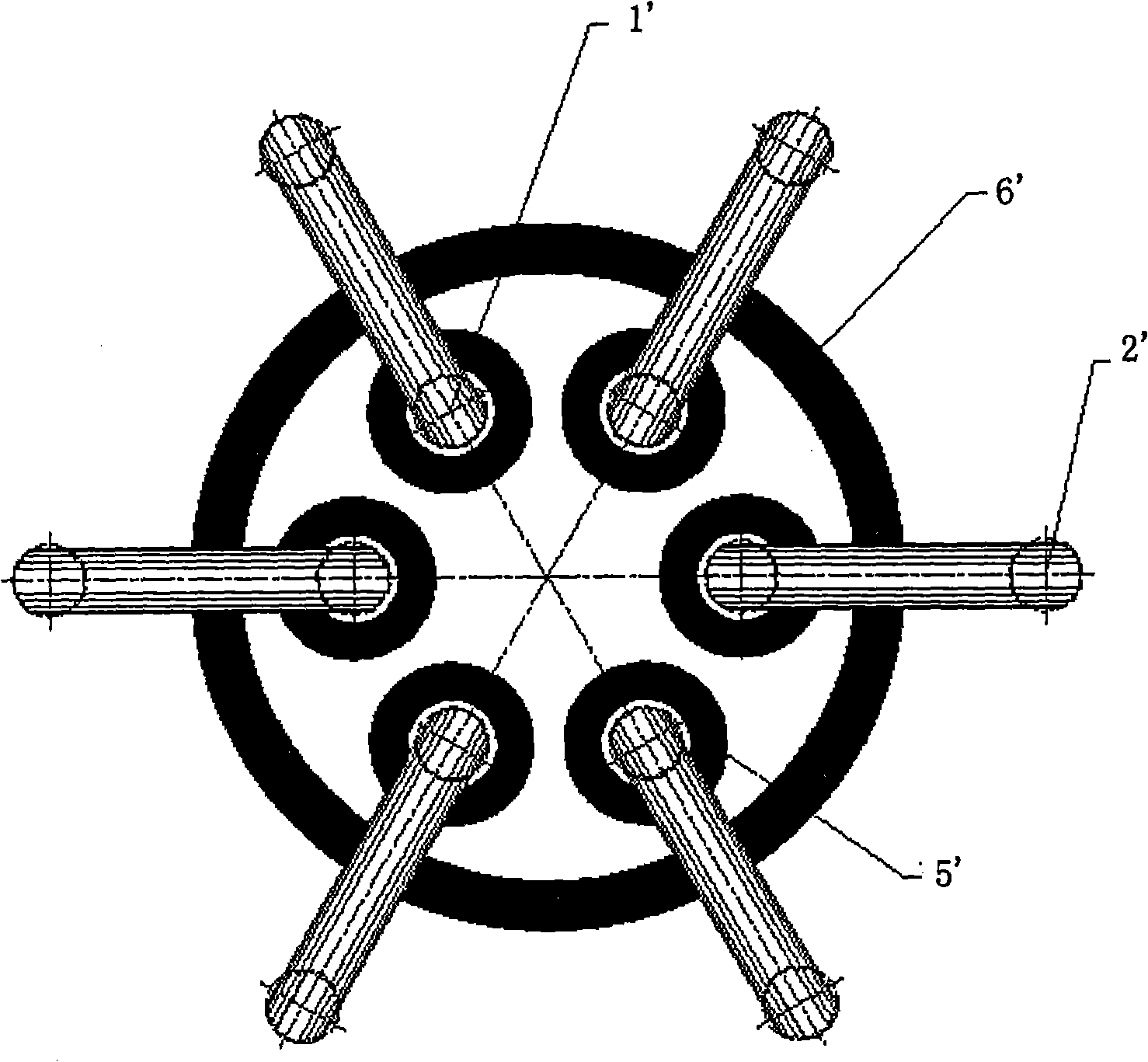

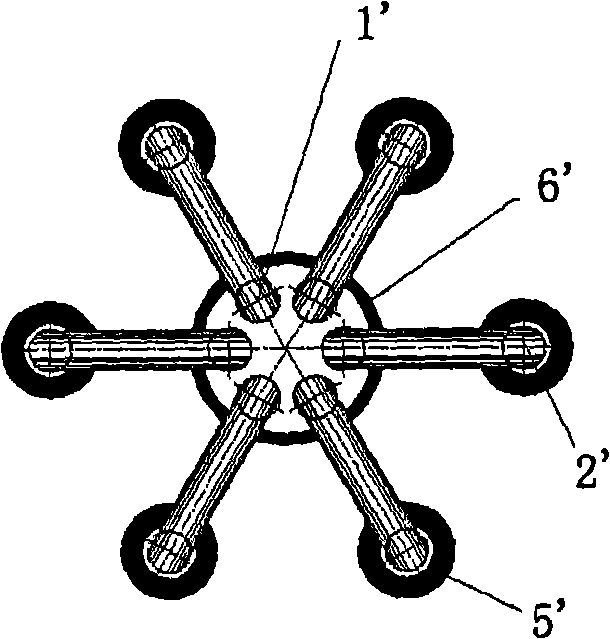

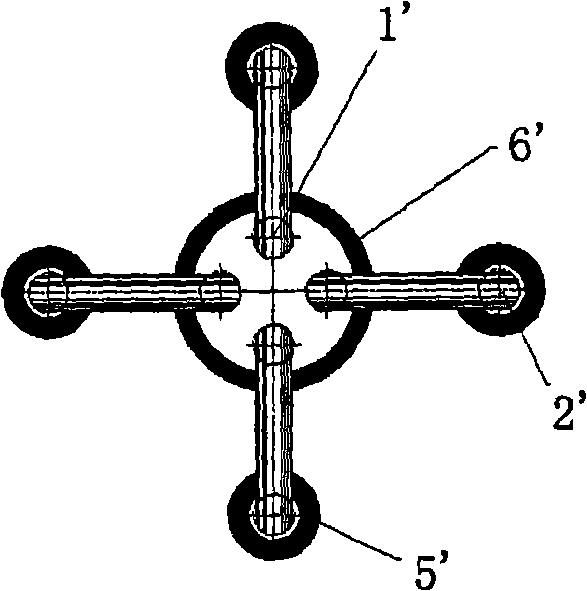

[0040] Such as Figure 3-1 to Figure 3-4 As shown, it is a schematic diagram of the compact iron core structure of the present invention. The compact iron core structure includes 2 to 6 square-shaped iron cores, Figure 3-1 It is a six-core structure, Figure 3-2 It is a four-core structure, Figure 3-3 It is a three-core structure, Figure 3-4 It is a two-core structure, and each square-shaped core includes a middle core column 1, a side column 2, and upper and lower yokes 3, 4, and each side column 2 is equipped with an AC winding 5, wherein the middle core column 1 The cross-sectional shape of the side column 2 is different from the cross-sectional shape of the side column 2. 2 to 6 of the intermediate core columns are compactly combined and assembled into a combined center column around the center for 360°, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com