Joint technique of aluminum wire motor

A process method, the technology of aluminum wire motor, which is applied in the direction of connecting contact materials, manufacturing motor generators, electrical components, etc., can solve the problems of reducing the service life of motors, loose connections, short wires, etc., and achieves convenient operation and is not easy to break Effect

Inactive Publication Date: 2008-10-22

SUZHOU SAMSUNG ELECTRONICS CO LTD

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

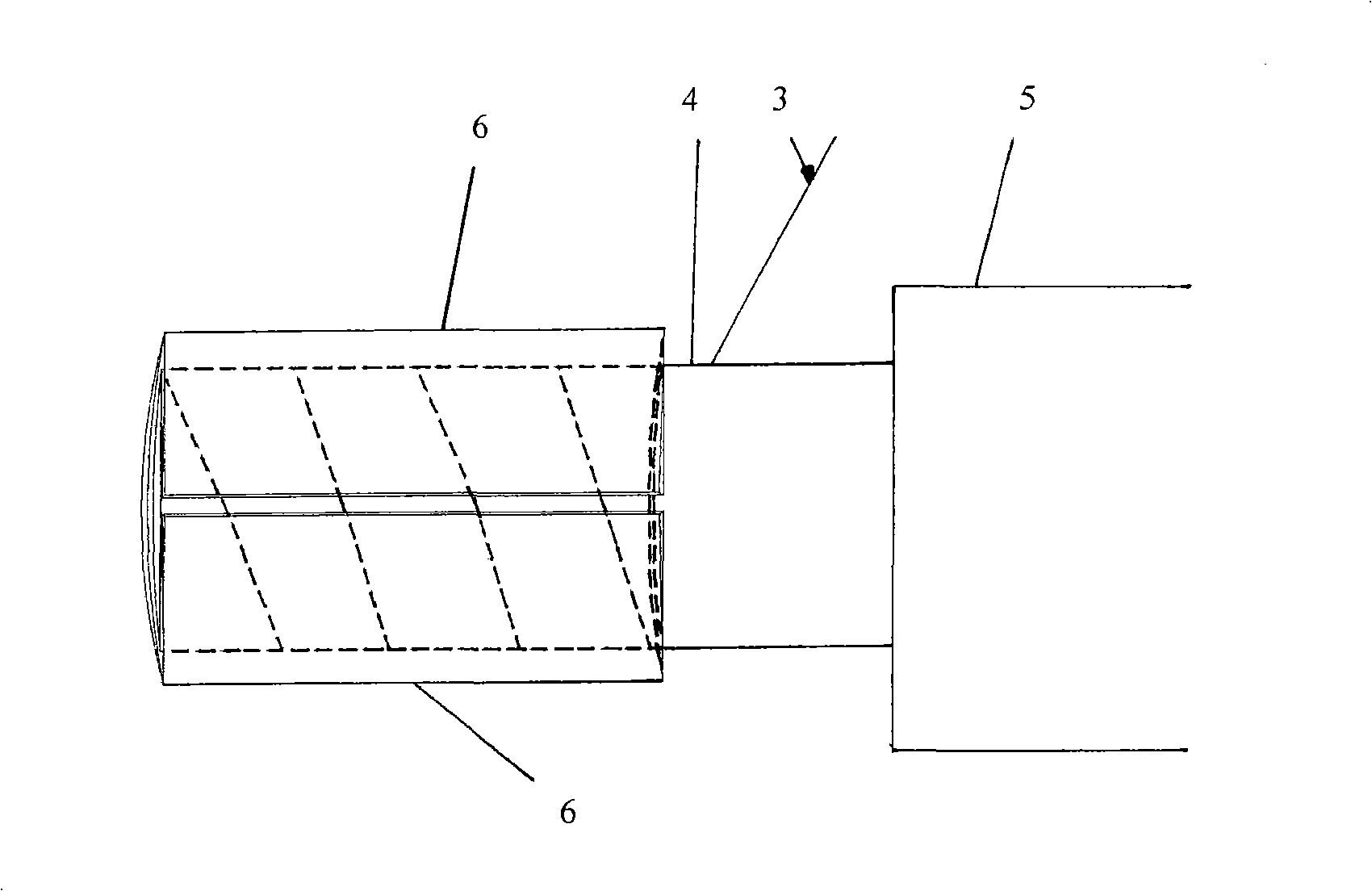

As shown in Figure 1, it includes aluminum wire 3, rolling sheet 6, copper wire lead-out wire 5, and copper wire 4. Rolling sheet 6 is used to connect the enameled wire and lead-out wire of the motor to connect the parts that are difficult to connect together. Copper wire 4 and aluminum wire 3; this copper-aluminum connection process is more convenient and quick to use on aluminum wire motors with large wire diameters, but it is prone to short wires, loose connections and scratches on the paint film when used on small wire diameters , resulting in reduced motor life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

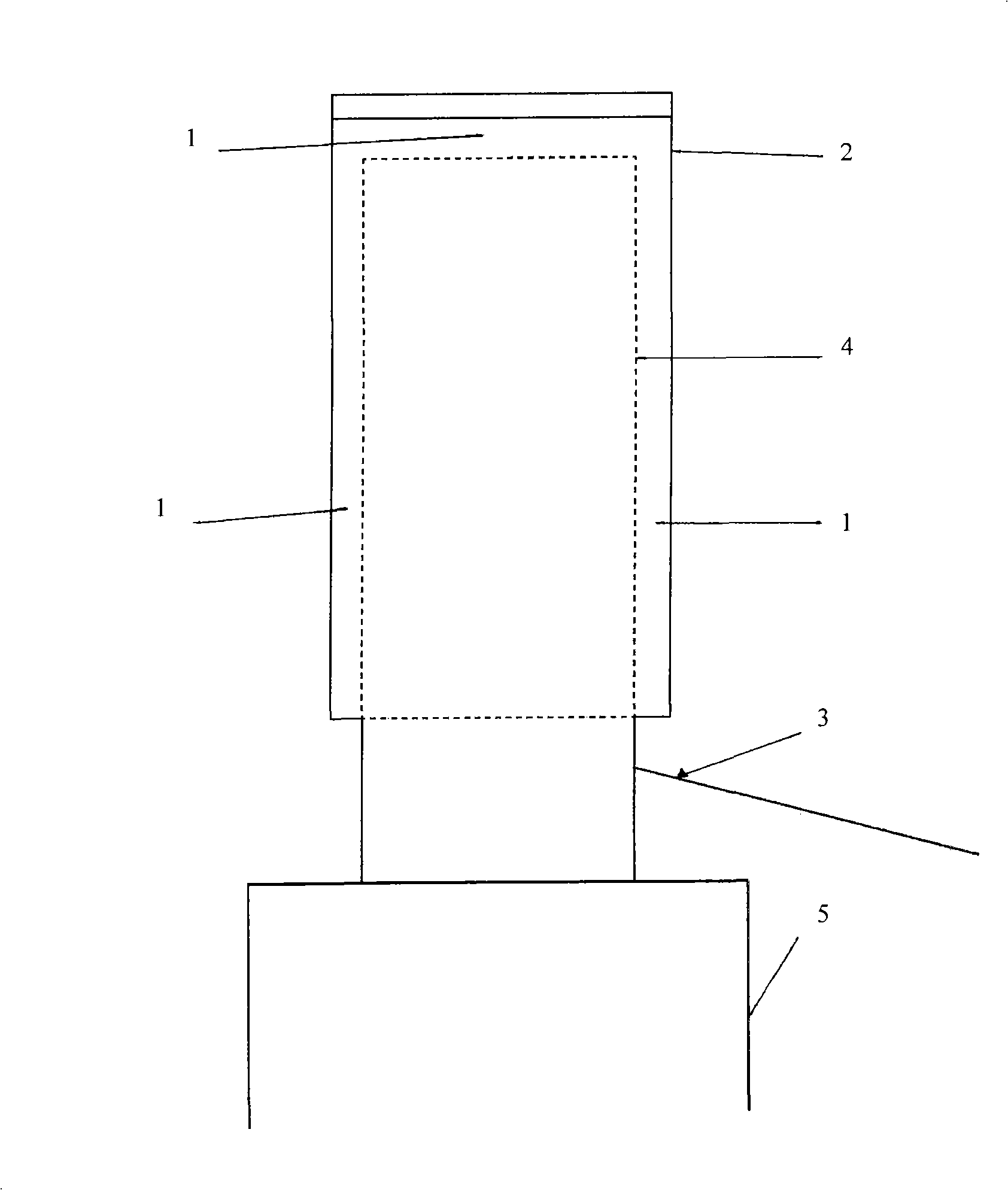

The invention relates to a joint process method of an aluminium wire motor. The method comprises the following steps that: firstly, lead-out wires of aluminium wires and copper wires are welded by using a soldering tin and scaling powder process of a common copper wire motor; secondly, the welded joint is immersed to hot melt adhesive at a temperature of between 100 and 120 DEG C for about 45 to 70 seconds in order that the hot melt adhesive and the joint are fully combined together, thereby achieving the insulation between the joint and the outside and strengthening the tight connection between the aluminium wires and copper wires; thirdly, a thermal shrinkage sleeve which can resist a temperature between 130 and 170 DEG C is arranged on the outside for fixing and molding the joint; fourthly, the joint is heated for 80 to 100 seconds to be fixed and molded. The method uses the process of the joint with colloid and the thermal shrinkage sleeve, adopts the mode of first heating melt adhesive and then the thermal shrinkage sleeve, is convenient to operate and uneasy to break the wire and can be applied to the manufacturing of small-scale aluminium wire motors.

Description

The joint process method of aluminum wire motor technical field The invention belongs to the field of motors, and relates to a motor joint, especially a manufacturing process of a small-diameter aluminum wire motor joint. Background technique At present, most of the joint technology used in aluminum wire motors adopts the processing method of rolling, which is applied to the situation of high-power and large-diameter aluminum wires; for small-diameter aluminum wire motors, the processing method of rolling is difficult to operate in the process. Moreover, the joint is easy to break, and there is a shortcoming that the combination is not tight. Aluminum wire and copper wire are different substances and cannot be mixed in a liquid state. Using soldering techniques of the past, solder does not hold the two substances together. Moreover, due to the relatively low oxidation temperature of aluminum, it is easy to form an oxide layer on the surface, which hinders welding. In t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01R4/62H02K15/00H02K5/22

Inventor 赵恩英宋伟张起云张振华

Owner SUZHOU SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com