Cheese-like package of highly crimpable conjugated fiber and process for the production of the same

A composite fiber and crimping technology, which is applied in the field of high-crimping composite fiber bobbin-like package yarn, can solve the problems of unpacking, poor unwinding of composite fibers, and increased bulge.

Inactive Publication Date: 2008-10-22

SOLOTEX CORP

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when obtaining a packaged yarn with an industrially usable coil weight, there are problems such as that the swelling increases and the package cannot be packaged, or it is difficult to take out the coil from the winding machine due to the hemming seam of the packaged yarn. Poor unwinding performance when unwinding PTT-type composite fibers from packaged yarn due to long-term exposure to high temperature

However, although the proposal of Patent Document 4 plays a certain role in releasing the dyeing quality of partially oriented polyethylene terephthalate yarns having an elongation at break of about 100 to 150%, it is not effective for PTTs with different molecular structures. Conjugate fibers and highly crimpable stretched yarns are difficult to solve the problems of maintaining the shape of the package yarn at high temperature and unwinding the PTT-based conjugate fibers in the innermost layer.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

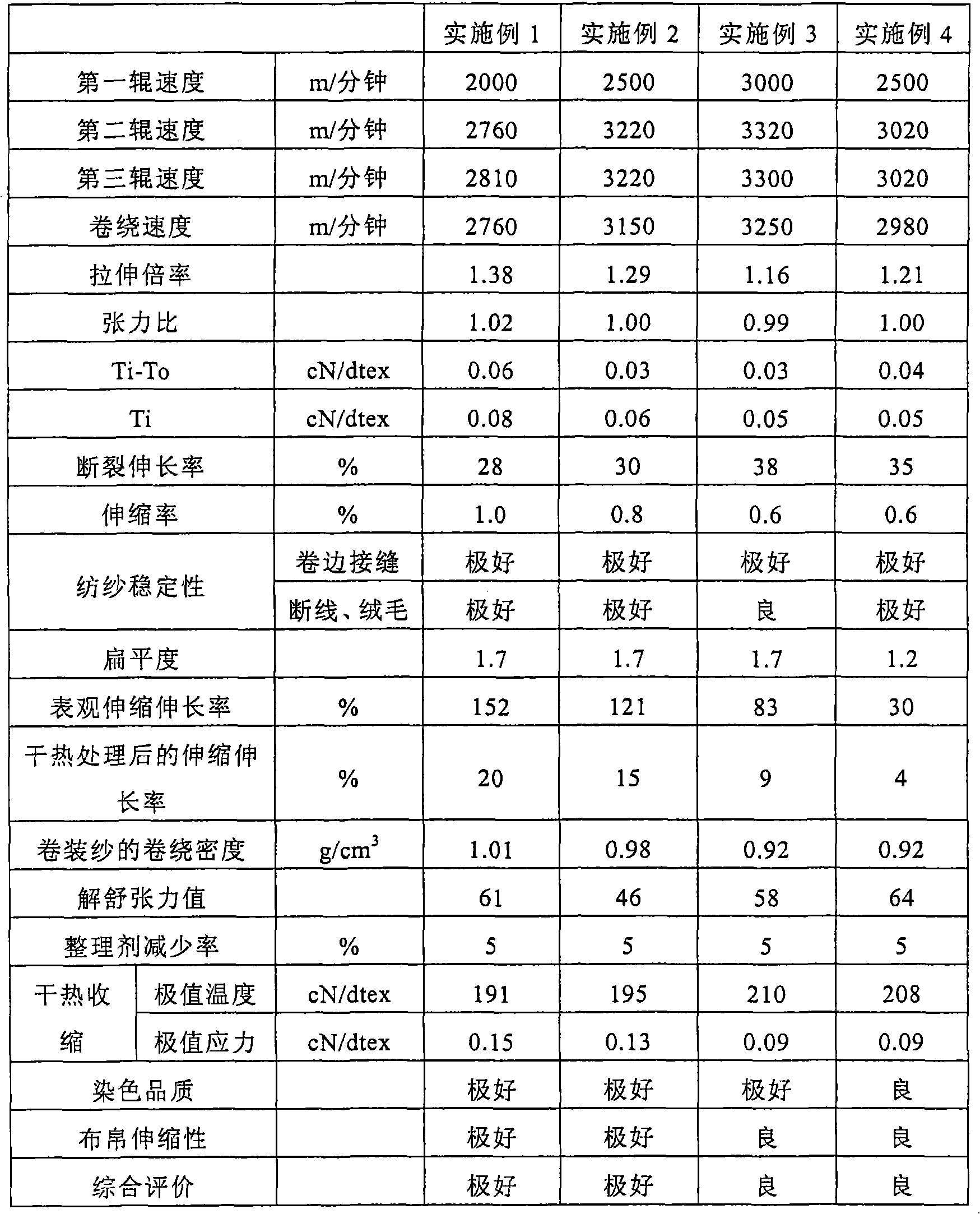

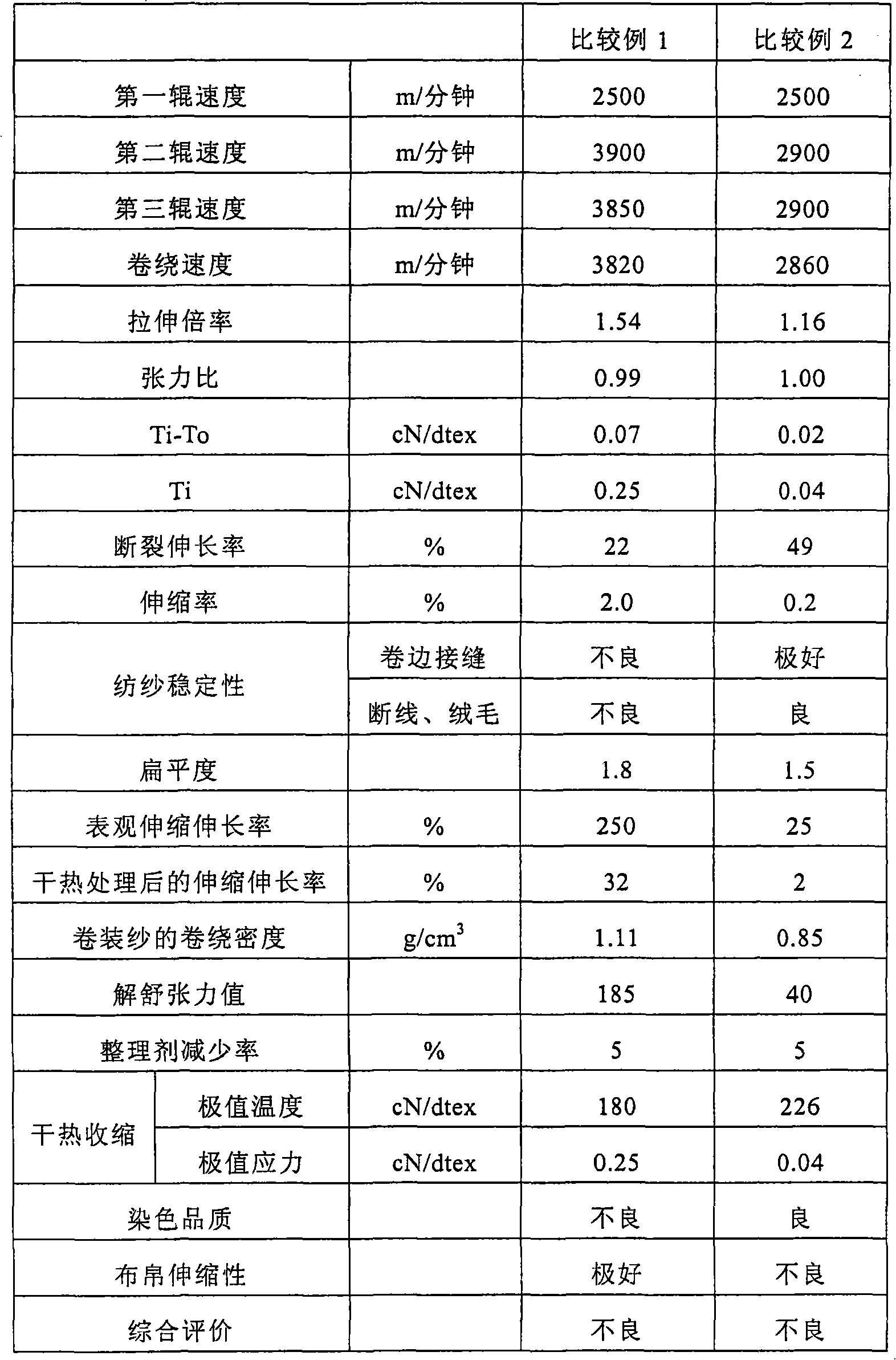

Embodiment 1~4、 comparative example 1 and 2

Embodiment 5~7、 comparative example 3 and 4

Embodiment 8 and 9、 comparative example 5 and 6

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Login to View More

Abstract

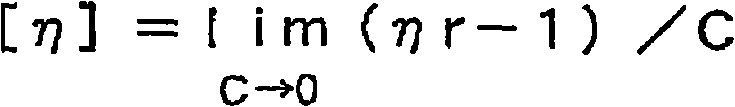

A cheese-like package of highly crimpable conjugated fiber obtained by laminating a paper tube with a conjugated fiber consisting of a group of single yarns obtained by joining, side by side, polytrimethylene terephthalates different in intrinsic viscosity which each comprise at least 90 % by mole of trimethylene terephthalate units and at most 10% by mole of other ester repeating units, characterized by satisfying the following requirements (1) to (4): (1) the crosssectional shape of the single yarn constituting the conjugated fiber is a flat one having a flatness (ratio of major axis to minor axis) of 1.1 to 3, (2) the apparent stretch elongation of the conjugated fiber is 30 to 200%, (3) the contact area (pressure reception area) (S cm<2>) between the paper tube and the conjugated fiber and the winding weight (W kg) satisfy the relationship of formula (1): 2 <= W <= 0.02S (1) with the proviso that 240 <= S <= 1000, and (4) the winding density of the cheese-like package is 0.92 to 1.05g / cm<3>.

Description

High-crimping composite fiber cheese-shaped package yarn and manufacturing method thereof Technical field The invention relates to a polytrimethylene terephthalate high-crimping composite fiber bobbin-like package yarn obtained by a direct spinning drawing heat treatment method and a manufacturing method thereof. Background technique Polytrimethylene terephthalate (hereinafter abbreviated as PTT) fiber has low modulus and excellent elongation recovery. Therefore, its flexibility and stretchability are advantages, and its industrial use has been increasing in recent years. In order to make the stretchability of the PTT fiber more remarkable, it is proposed to use PTT in at least one component constituting the single yarn or a side-by-side two-component composite fiber (hereinafter referred to as PTT with different intrinsic viscosities) in the two components. PTT composite fiber). PTT-based composite fibers that use PTT with different intrinsic viscosities in the two components...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D02J1/22D01D7/00D01F8/14D02G1/00D02G3/02D02G3/24

CPCB65H55/04D02G1/00D02G1/18B65H2701/3132Y10T428/1324D01D5/32D01F8/14D02G3/02D02G3/24D02J1/22

Inventor 山下明小柳正松尾辉彦

Owner SOLOTEX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com