Biomass fuel thermal decomposition vaporization combustion method and apparatus

A technology of biomass fuel and combustion method, which is applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of irreplaceable, large investment, complex system, etc., and achieve the effect of reducing dust effect, small resistance, and wide application range

Inactive Publication Date: 2008-10-29

韩枫

View PDF0 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the various methods currently produced have problems such as complex systems, large investment, and poor efficiency, and cannot replace the commonly used coal-fired boilers.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

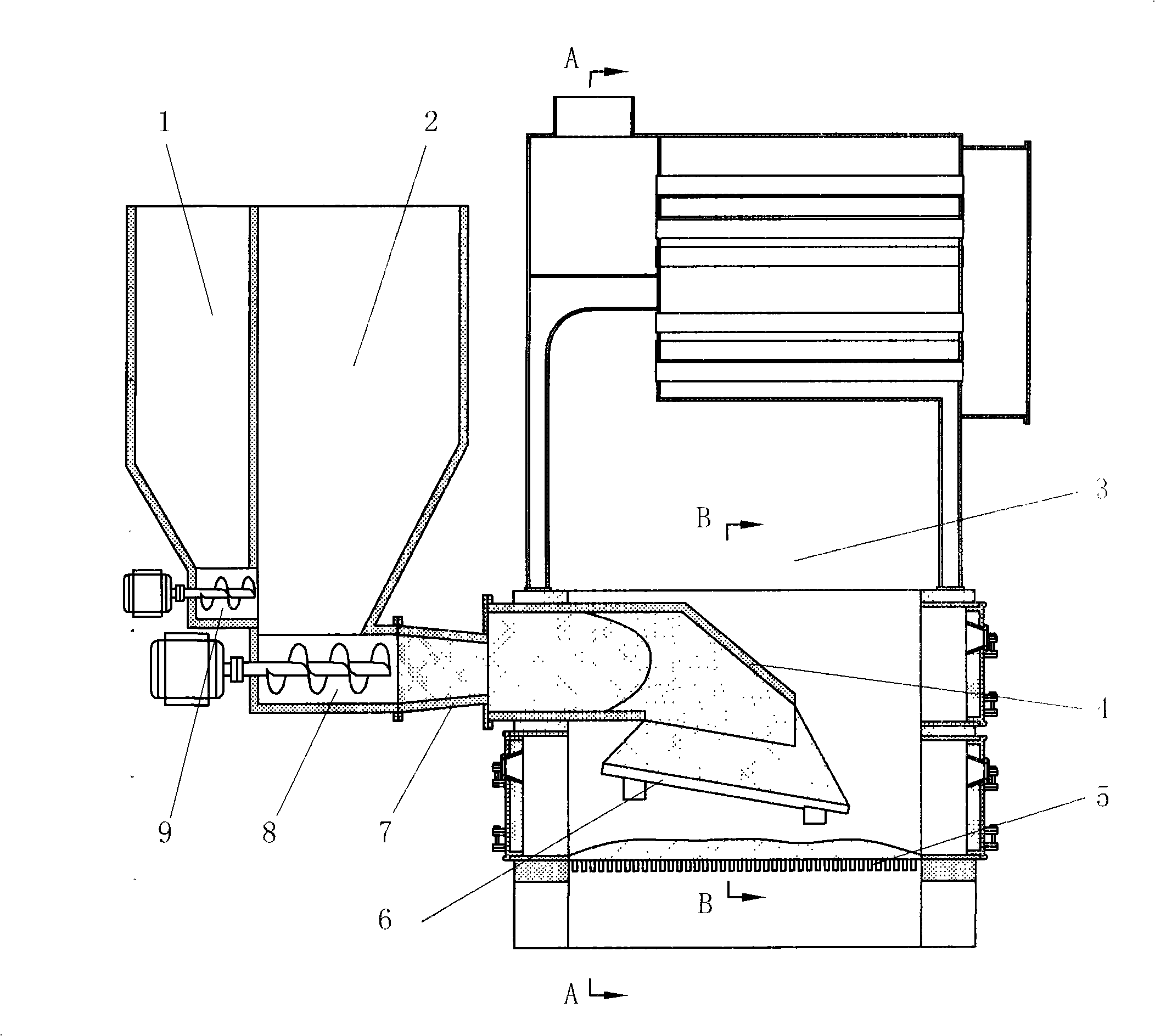

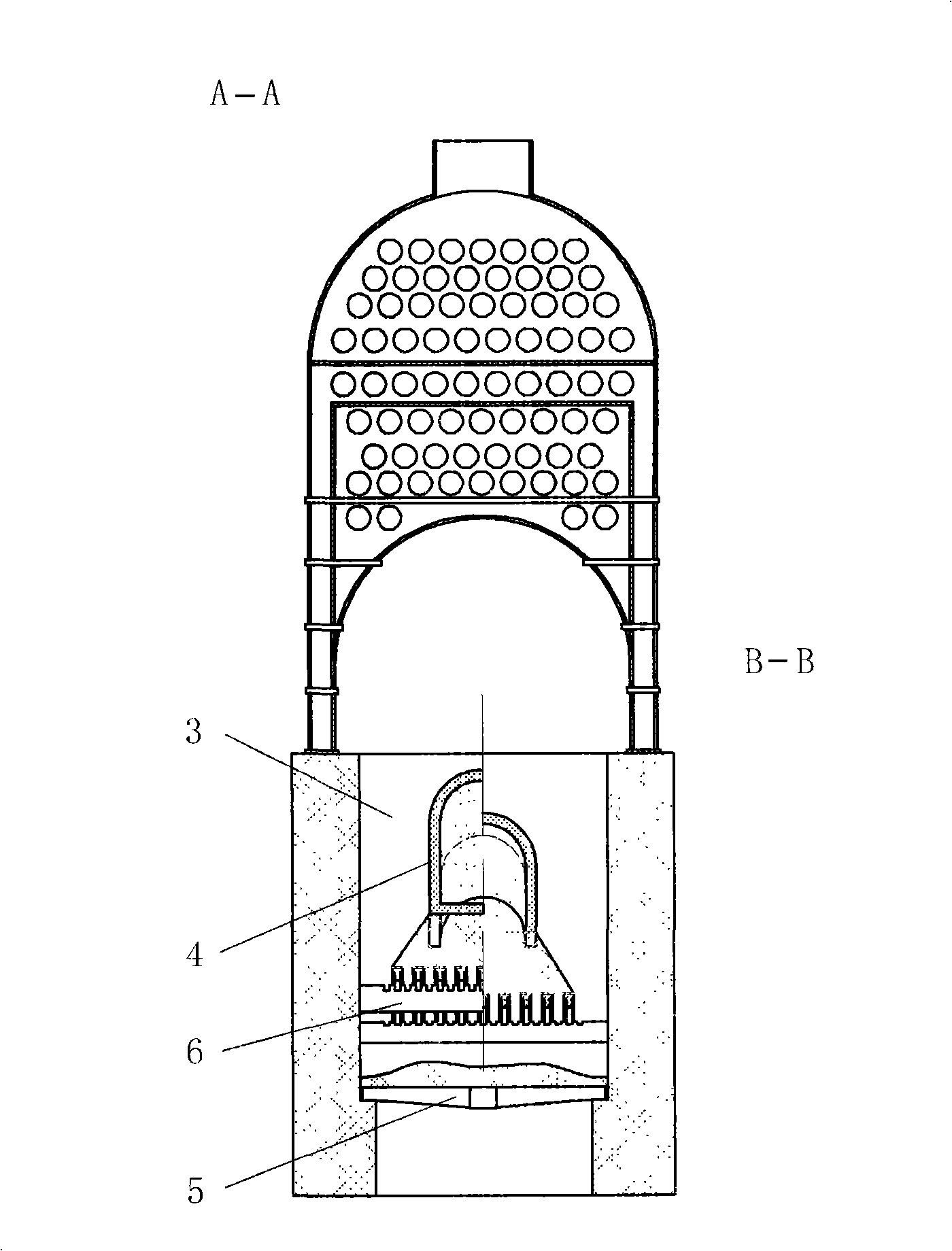

A gasification and combustion device for biomass fuel pyrogenation is provided with the technical proposal as follows: a pyrogenation device is added in the hearth of a boiler and is composed of a pyrogenation cylinder and a pyrogenation furnace, and a material feeding device is arranged out of the hearth. The biomass fuel is pushed forward by a main spiral propeller and is gradually compressed when passing through a fuel passage to improve the degree of compaction and prevent pyrogenation gas from escaping, the biomass fuel is pushed to move on by the subsequent fuel after entering the pyrogenation cylinder, and gradually falls on the pyrogenation furnace bed to come into contact with oxygen for being ignited, the pyrogenation cylinder is heated by flame after ignition, the biomass fuel in the pyrogenation cylinder is heated to a temperature being higher than that of pyrogenation, the biomass fuel carries out gas-solid separation, the gas can only escape from the flame on the pyrogenation furnace bed, and the combustible component therein is subjected to forced ignition, the flame goes up to the upper part of the hearth along the latearal face of the pyrogenation cylinder and is burnt out, at the same time the pyrogenation cylinder is heated for the continuous pyrogenation reaction therein, and the solid on the pyrogenation furnace bed is broken to pieces, and falls or continuously burns on the pyrogenation furnace bed.

Description

Biomass fuel pyrolysis vaporization combustion method and device technical field The invention relates to a biomass fuel pyrolysis vaporization combustion technology, in particular to a biomass fuel pyrolysis vaporization combustion method and device. Background technique Due to the increasing shortage of coal resources, countries all over the world are researching biomass combustion utilization technology to solve the problems caused by the energy crisis. At present, the biomass-fired boilers that have been launched are all developed on the basis of coal-fired boiler technology. However, due to the high water content, low volatile point, high volatile content and low energy density of biomass fuel, it is difficult to form stable combustion conditions with coal-fired boiler technology. Therefore, the feasible method is to vaporize or carbonize the biomass to increase the energy density, and then send it to the boiler for combustion. However, the various methods produced a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23G5/027F23K3/14

Inventor 韩枫

Owner 韩枫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com