Changeable built-in live center

A live top and replaceable technology, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems that the rotation accuracy cannot meet the processing accuracy, the bracket is worn, and the processing benchmark is lost, so as to improve the enterprise market. Competitiveness, ease of replacement and maintenance, and improved accuracy and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

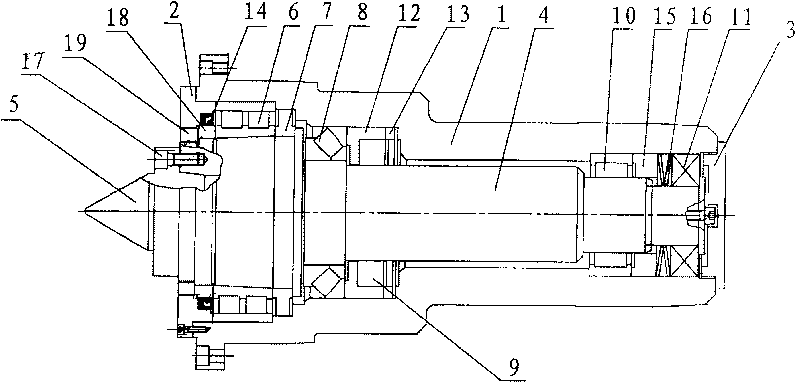

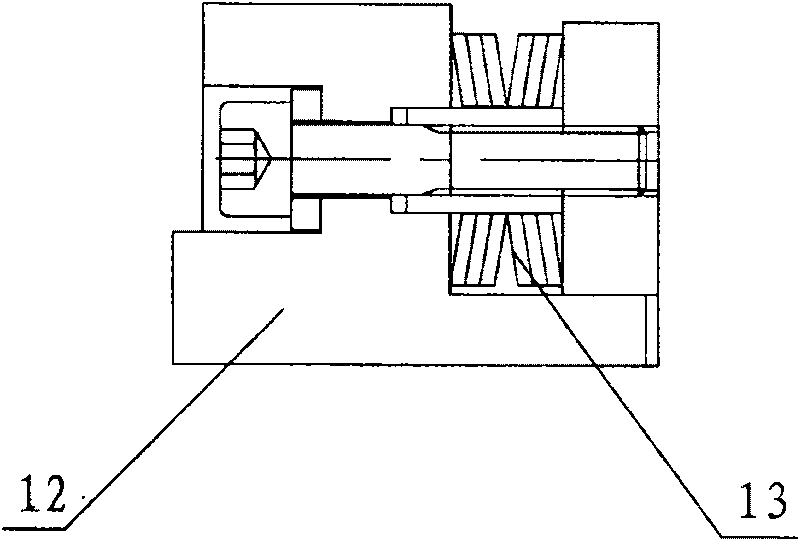

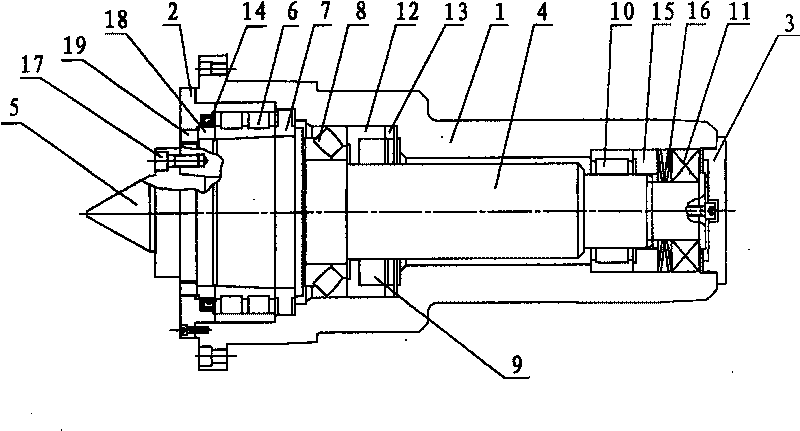

[0021] Such as figure 1 The replaceable built-in live center shown includes seat shell 1, front end cover 2, rear end cover 3, top shaft 4 installed in seat shell 1 and center head 5 arranged on top shaft 4, the front end of top shaft 4 is connected with Double-row short cylindrical roller bearings 6 are installed between seat shells 1, needle roller bearings 10 and deep groove sealed bearings 11 are arranged at the rear end of the top shaft 4, and adjustment pads 7 are arranged on one side of double-row short cylindrical roller bearings 6 , the top head 5 is a replaceable movable component, fixed on the top shaft 4 by the fastening screw 17, a thrust self-aligning roller is arranged between the step surface in the middle of the top shaft 4 and the matching step surface inside the seat shell 1 Bearing 8, the thrust self-aligning roller bearing 8 is pressed by the disc spring 16 arranged at the rear end of the top shaft 4, and the top shaft 4 is pulled back and always pressed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com