Calcination process of boron ore powder

A calcination process, a technology of boron ore powder, applied in boron/boride and other directions, can solve the problems of long calcination period, low energy utilization rate, low activation rate of iron ore, etc., to achieve stable product quality, optimized process, process flow simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

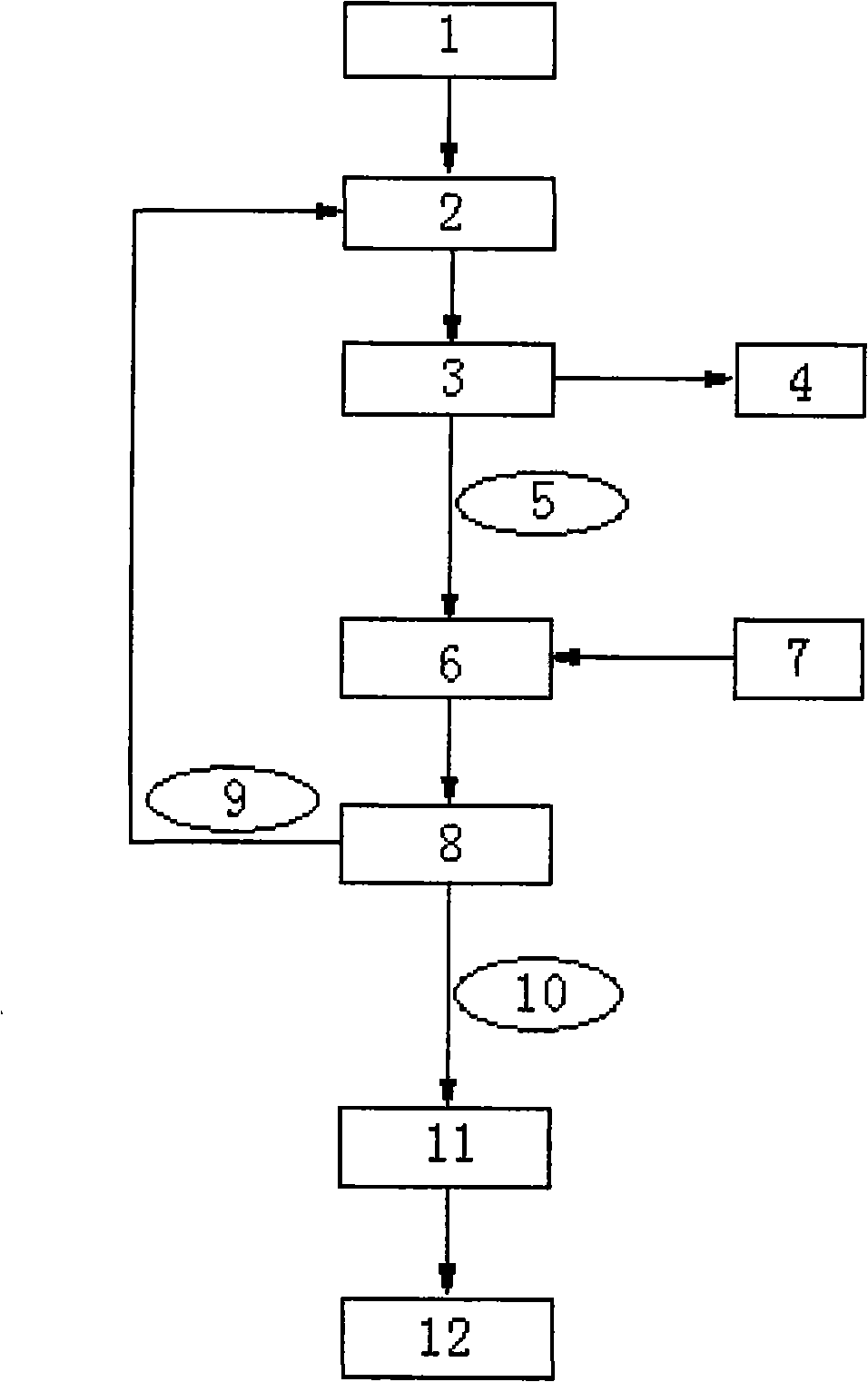

Image

Examples

Embodiment 1

[0009] Use the gas-fired hot blast stove as the heat source of the calcination furnace, add boron iron ore with a water content of 20% into the dryer, break it into boron ore powder and dry it for 1-10 seconds, and then the mixture of boron ore powder and air will undergo gas-solid separation of semi-finished products The exhaust gas is purified and discharged, and the dry solid is sent to the calciner. At the same time, hot air is added as the calcining heat source. The calcining time is 1-10s, and the temperature in the calciner is 1000-1150°C. The air pressure in the calciner is controlled by changing the wind speed of the induced draft fan. It is -100~-200Mpa. Afterwards, the gas-solid mixture enters the finished product gas-solid separator from the outlet of the calciner, and the hot gas in it is recycled into the dryer as a drying heat source, and the calcined solid is cooled by the air cooler to become a finished product, and is captured to the storage bin.

Embodiment 2

[0011] Use the coal-fired hot blast stove as the heat source of the calcination furnace, add boronite with a water content of 25% into the dryer, and after being broken into boron ore powder and dried for 10 to 15 seconds, the mixture of boronite and air passes through the semi-finished gas Solid separator, in which the exhaust gas is purified and discharged, the dry solid is sent to the calciner, and hot air is added as the calcining heat source at the same time, the calcining time is 10-15s, the temperature in the calciner is 1000-1200 °C, and the calciner is controlled by changing the wind speed of the induced draft fan The internal air pressure is -200~-300Mpa. Afterwards, the gas-solid mixture enters the finished product gas-solid separator from the outlet of the calciner, and the hot gas in it is recycled into the dryer as a drying heat source, and the calcined solid is cooled by the air cooler to become a finished product, and is captured to the storage bin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com