Internal combustion engine noise elimination, waste gas purification, discharging device

A technology of exhaust gas purification and internal combustion engine, which is applied in the direction of machines/engines, noise reduction devices, exhaust devices, etc., and can solve problems such as unsatisfactory treatment effects, pollution of the natural atmosphere, and lagging treatment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

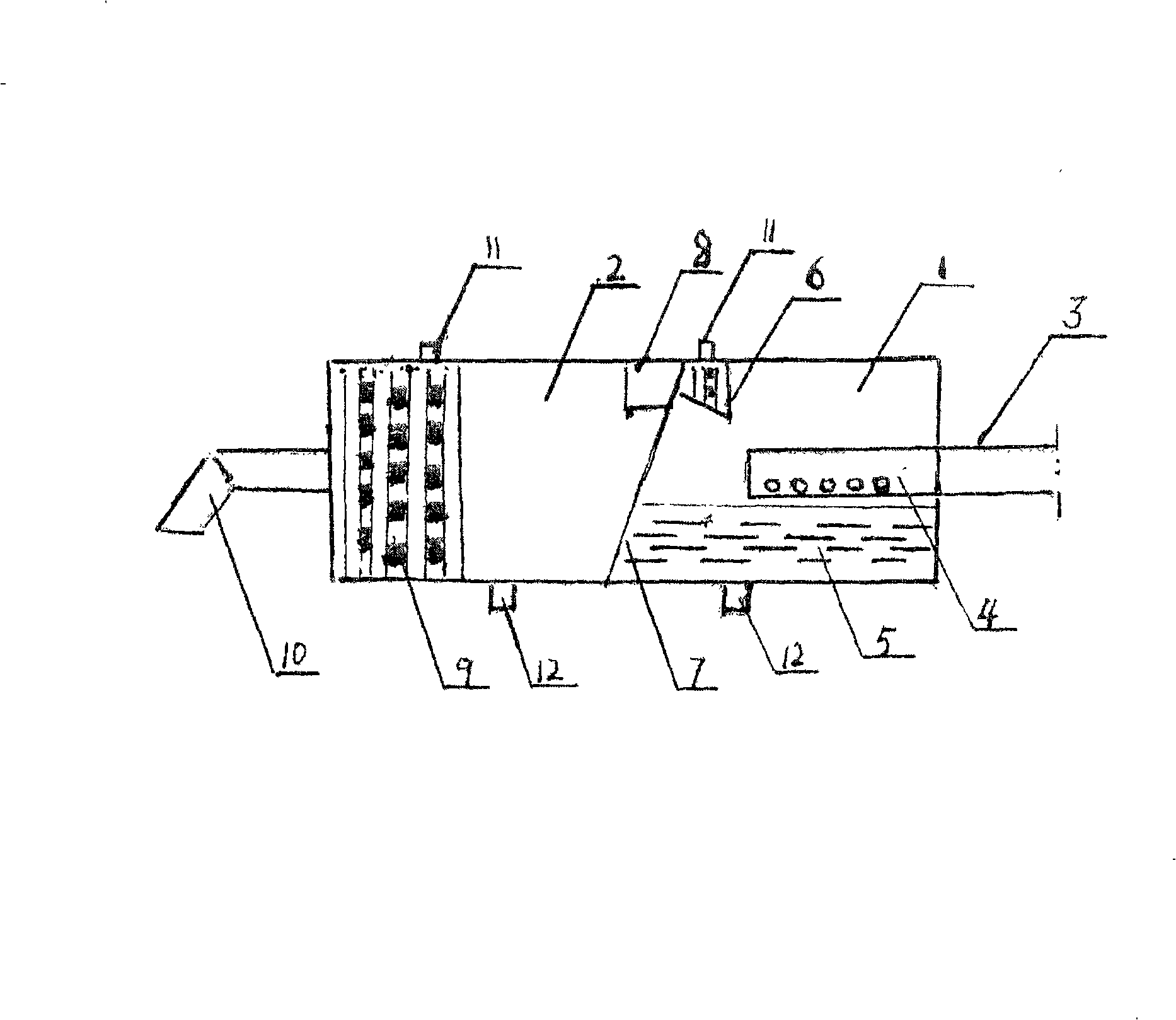

[0009] It can be seen from the drawings that the internal combustion engine noise reduction, exhaust gas purification, and discharger are divided into two parts: a wet filter area and a dry filter area. Bile duct 4, there are several air outlets below the bile duct 4 to send the exhaust gas to the water surface 5, and the exhaust gas with heat rushes into the water surface 5 for humidification and cooling. At this time, the waste gas forms a vortex and is filtered and purified again by the multi-layer filter screen 9, and is discharged to the ground from the waste gas discharge pipe 10. The specific gravity of the waste gas is lowered by humidification than the natural atmosphere, which can curb the diffusion of the waste gas in the natural atmosphere. . Internal combustion engine noise reduction, exhaust gas purification, multi-stage barrier of the discharger, and secondary filtration are also very ideal for the noise reduction effect of the internal combustion engine.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com