Optical power detection apparatus and method

A technology of optical power detection and power, which is applied in the field of optical communication, can solve problems such as the inability to make good use of digital amplifiers, narrow detection range, and low voltage resolution, so as to facilitate debugging and fault location, improve sampling accuracy, and ensure reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

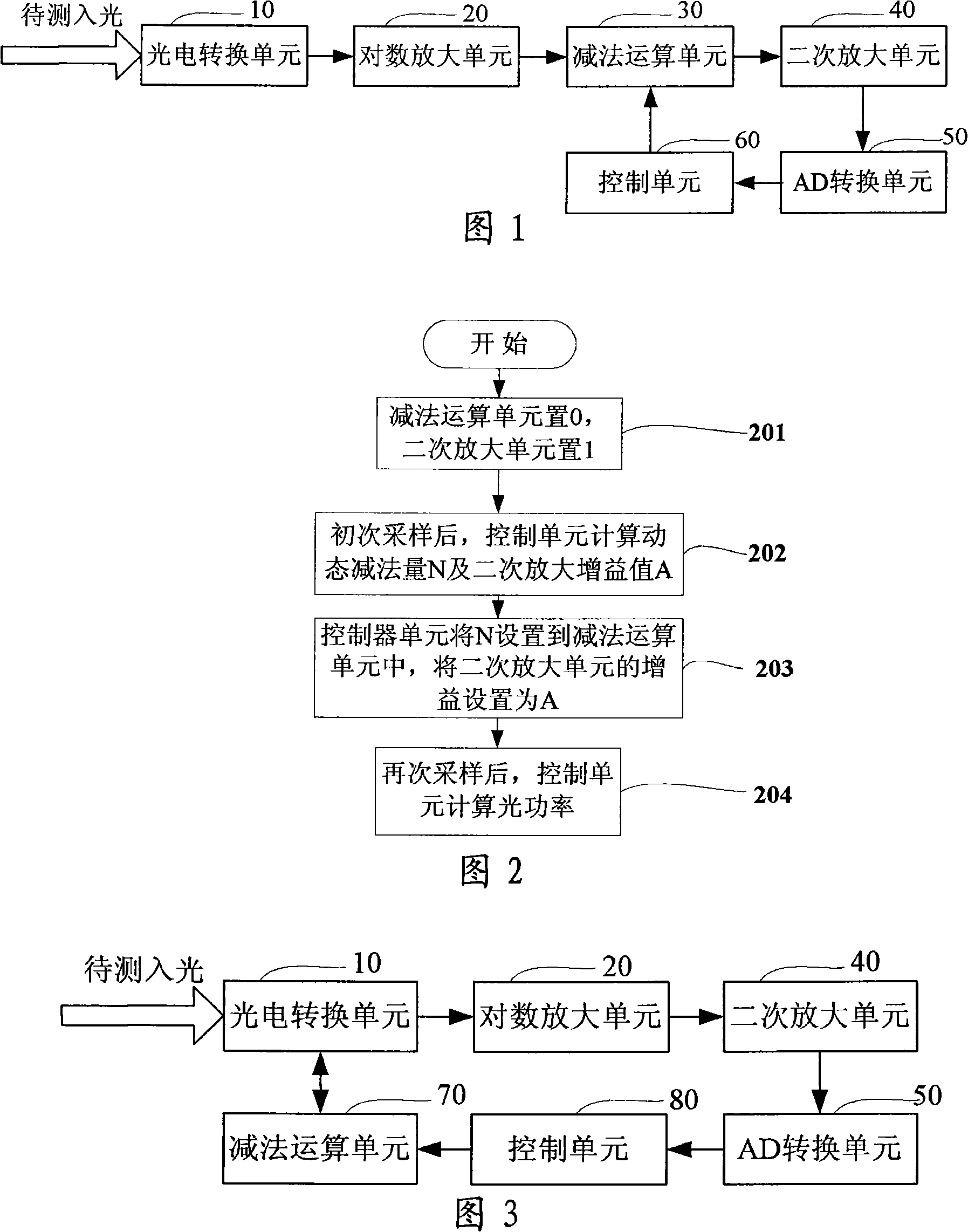

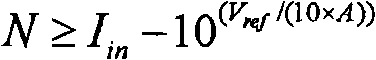

[0039] A high-precision optical power detection device, as shown in Figure 1, includes a photoelectric conversion unit (10), a logarithmic amplification unit (20), a subtraction unit (30) and a secondary amplification unit (40) connected in sequence, wherein The subtraction unit (30) is also connected to the control unit (60), the secondary amplification unit (40) is connected to the AD (analog-to-digital) conversion unit (50), and the control unit (60) is connected to the AD conversion unit (50). The following is a detailed introduction to the functions of each unit.

[0040] A photoelectric conversion unit (10), used for photoelectric conversion, can use an APD or PIN conversion circuit;

[0041] A logarithmic amplification unit (20), configured to logarithmically amplify the voltage output result of the photoelectric conversion;

[0042] The subtraction operation unit (30) performs subtraction operation on the voltage output result of the logarithmic amplification unit (20...

Embodiment 2

[0063] The optical power detection device provided by this embodiment is shown in Figure 3, and the device includes a photoelectric conversion unit (10), a logarithmic amplification unit (20), a secondary amplification unit (40), and an AD conversion unit (50) connected in sequence. ), a control unit (80) and a subtraction unit (70), wherein the photoelectric conversion unit (10) is also connected to the subtraction unit (70). The following is a detailed introduction to the functions of each unit.

[0064] A photoelectric conversion unit (10), used for photoelectric conversion, can use an APD or PIN conversion circuit;

[0065] A logarithmic amplification unit (20), configured to logarithmically amplify the shunted circuit voltage;

[0066] The subtraction unit (70) can be realized by using a controllable current source, and part of the current is shunted from the PD circuit, and this part of the current can be converted into a voltage value correspondingly. In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com