Combined insoles and manufacturing method thereof

A production method and technology of insoles, which are applied in the field of insoles, can solve problems such as low proportion of activated carbon, poor deodorization effects, and insufficiently stable structure, and achieve the effect of good adhesion, not easy to deform, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

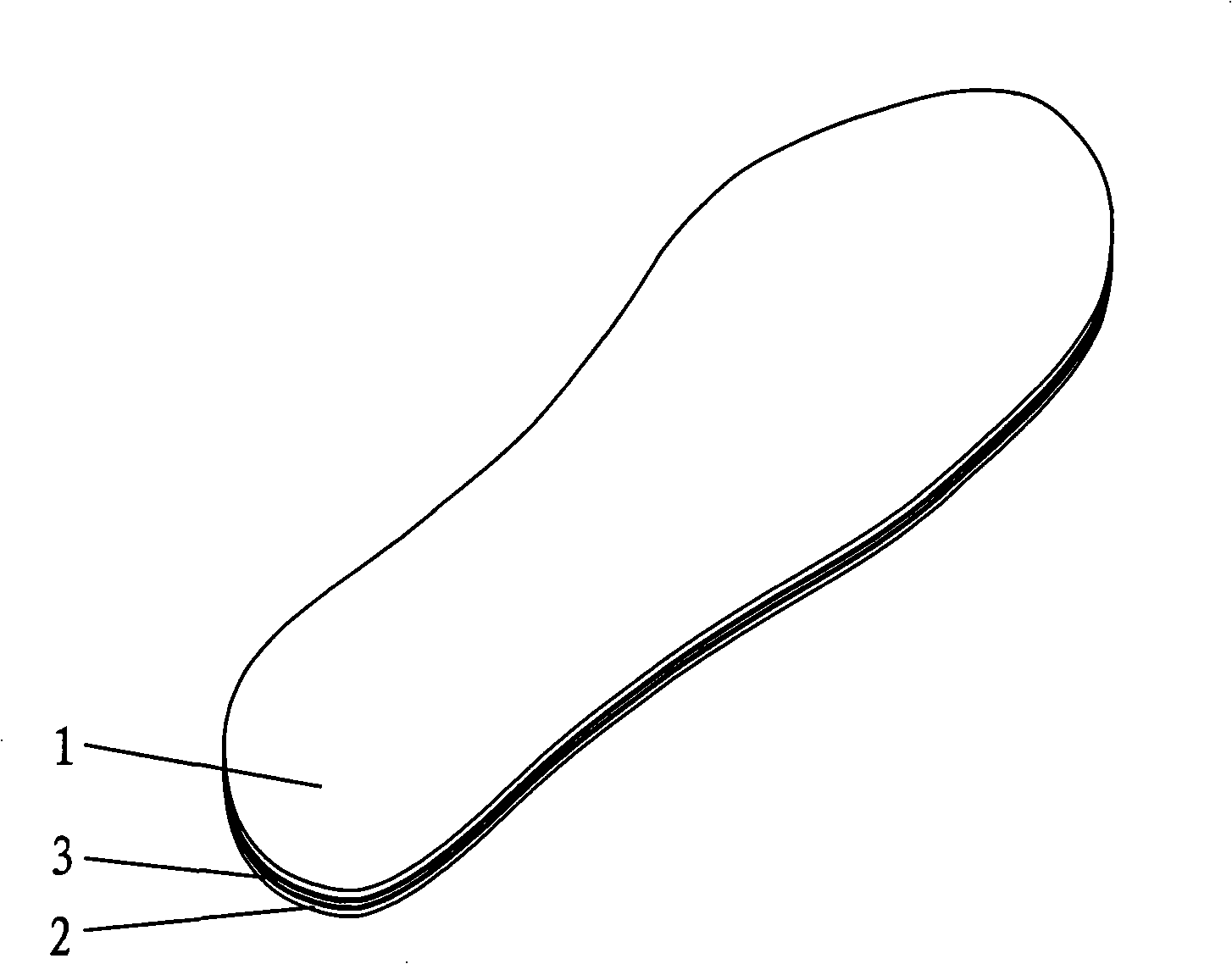

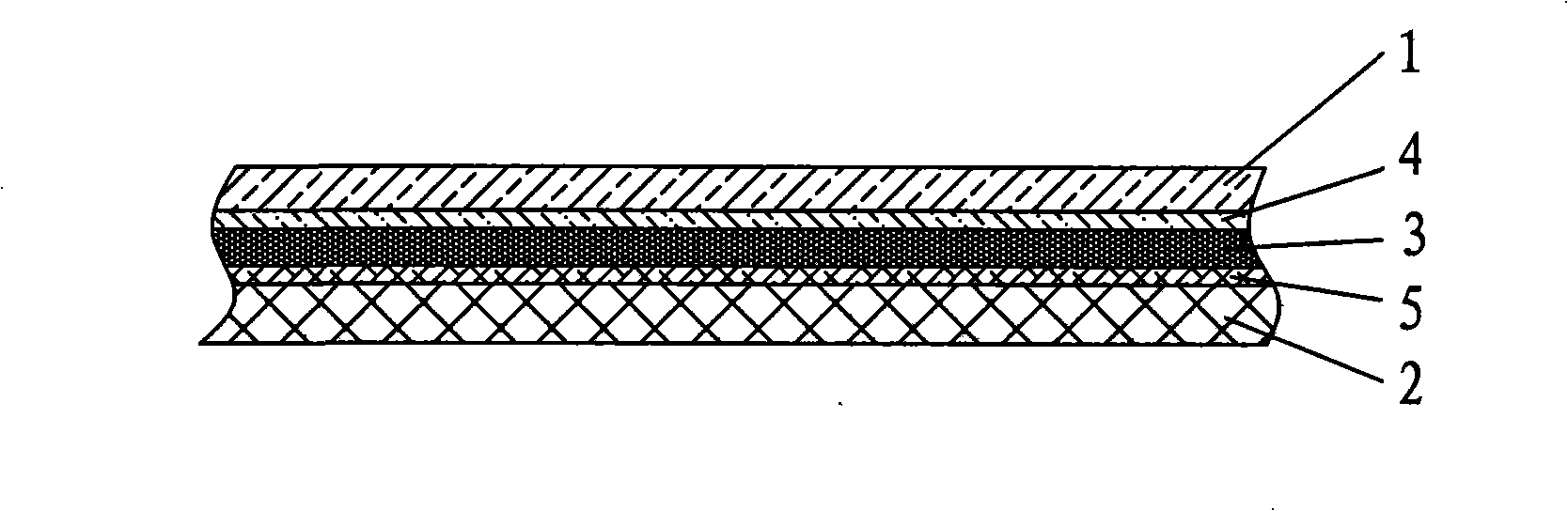

[0023] See Figure 1~2 , a composite insole, which comprises a surface layer 1, a non-woven fabric layer 4, an activated carbon interlayer 3, a fine cloth layer 5 and a bottom layer 2 from top to bottom, and the layers are bonded together by hot melt adhesive, wherein the activated carbon The granular activated carbon in the interlayer is bonded together by hot melt adhesive, wherein the non-woven fabric layer 4 can also be a knitted fabric layer or a woven fabric layer, etc., and the fine cloth layer 5 can also be a non-woven fabric layer, a knitted fabric layer or a woven fabric layer. layers etc. The activated carbon interlayer is prepared according to the volume ratio of 75% to 85% of granular activated carbon and 15% to 25% of hot melt adhesive, and the granular activated carbon is 20 mesh particles.

[0024] The surface layer 1 is a porous cloth layer or a leather layer, and the cloth layer or the leather layer has good air permeability, so that sweat and air can pass t...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the manufacturing method of the above-mentioned composite insole comprises the following steps:

[0033] A. Sprinkle a layer of 100-mesh hot melt adhesive powder on the non-woven fabric layer 4. After baking and heating in an oven at 250°C for 15 seconds, place the surface layer 1 on the side of the non-woven fabric layer 4 with hot melt adhesive At the same time, the surface layer 1 and the non-woven fabric layer 4 are quickly hot-pressed together by a pressure wheel at 120°C to obtain a surface composite layer, which is cooled to room temperature by a cooling wheel and rolled up for use;

[0034] B. Coat a layer of hot melt adhesive on the latex layer, then place the muslin layer 5 on the side of the latex layer coated with hot melt adhesive, and at the same time, the muslin layer and the latex layer are quickly baked and thermally bonded in an oven at 120°C together to make the bottom composite layer;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com