Method for quickly processing heavy layer soft soil foundation

A soft soil foundation and fast technology, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as inability to backfill, rigidity and integrity that cannot meet construction requirements, and meet construction settlement requirements and bearing capacity requirements , low project cost, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

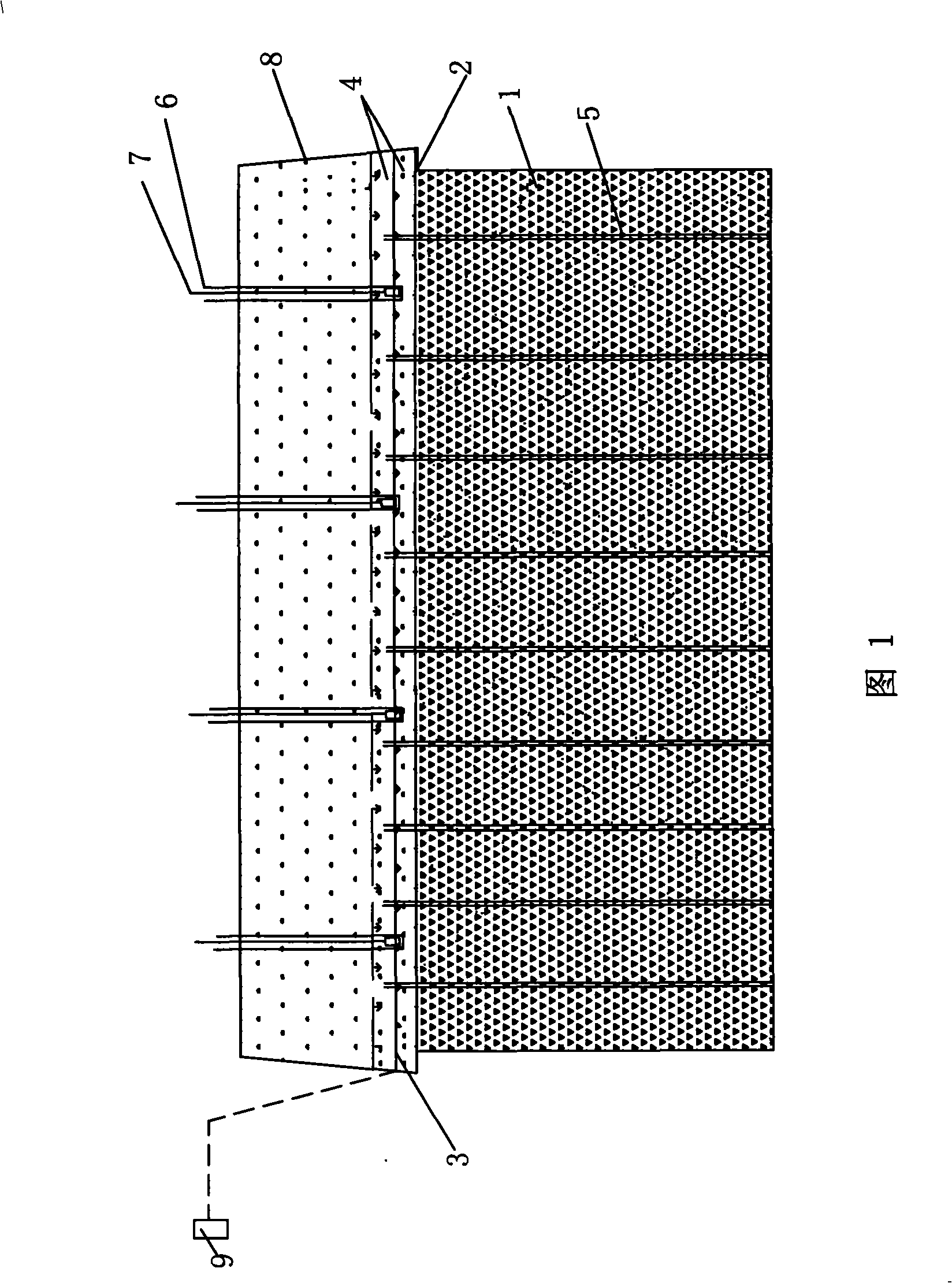

[0032] Refer to Figure 1. Be 8m in thickness, on the silt layer 1 that surface water content is 38%, lay bamboo grid 2, described bamboo grid 2 is the grid that is 0.5cm in thickness, the width is 1.8cm, and the length is 2.5m bamboo strips criss-cross to form woven body, the horizontal length of the grid is 10cm, and the vertical length is 10cm. The interlaced connection of the bamboo strips on the bamboo grid is fixed by the drilling holes arranged on it with connecting bolts. The unit weight of the bamboo grid 2 is 5kg / m 2 . After completing the laying of the bamboo grid 2, a medium-coarse sand layer 4 with a thickness of 0.8m is artificially laid thereon immediately, and the thickness needs to be kept uniform during laying.

[0033] There are several vertically penetrating plastic drainage boards 5 arranged in the mud layer 1 , and the upper ends of the plastic drainage boards 5 enter into the medium-coarse sand layer 4 .

[0034] Buried water collection wells 6 at inter...

Embodiment 2

[0041] Refer to Figure 1. The difference with embodiment 1 is: be 12m in thickness, be that 300g / m is laid on the silt layer 1 that surface water content is 50% 2 One layer of knitted geotextile, and then lay bamboo grid 2 on it, and the bamboo grid 2 is a grid-like weaving body formed by criss-crossing bamboo strips with a thickness of 0.8cm, a width of 2.0cm, and a length of 3.0m. The horizontal length of the grid is 12cm, and the vertical length is 12cm. The interlaced connection parts of the bamboo strips on the bamboo grid are fixed by connecting bolts through the drill holes arranged on it. The unit weight of the bamboo grid 2 is 5kg / m 2 . After the laying of the geotextile and the bamboo grid 2 is completed, a medium-coarse sand layer 4 with a thickness of 1.0 m is artificially laid on it immediately, and the thickness needs to be kept uniform during laying.

[0042] All the other steps are the same as in Example 1.

[0043] After testing, the silt soil layer treated...

Embodiment 3

[0045] Refer to Figure 1. The difference with embodiment 1 is: be 15m in thickness, on the silt layer 1 that surface layer water content is 80%, laying one deck specific gravity earlier is that 300g / m 2 Knitted geotextile, and then pave bamboo grid 2 on it, described bamboo grid 2 is a grid-like weaving body formed by criss-crossing bamboo strips with a thickness of 1.0cm, a width of 2.5cm, and a length of 4.0m. The horizontal length is 15cm, and the vertical length is 15cm. The interlaced joints of the bamboo strips on the bamboo grid are fixed by connecting bolts through the drill holes arranged on it. The unit weight of the bamboo grid 2 is 5kg / m 2 . After the laying of the geotextile and the bamboo grid 2 is completed, a medium-coarse sand layer 4 with a thickness of 1.5m is artificially laid on it immediately, and the thickness needs to be kept uniform during laying.

[0046] All the other steps are the same as in Example 1.

[0047] After testing, the silt soil layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com