Vibration damping base corner

A bottom angle and bottom surface technology, which is applied in the direction of non-rotational vibration suppression, support machine, engine frame, etc., can solve the problems of high manufacturing cost, insignificant vibration damping effect of the bottom angle of the compressor, complex structure, etc., to reduce mold Cost, simplicity of shape, effect of increasing profit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The damping base angle of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

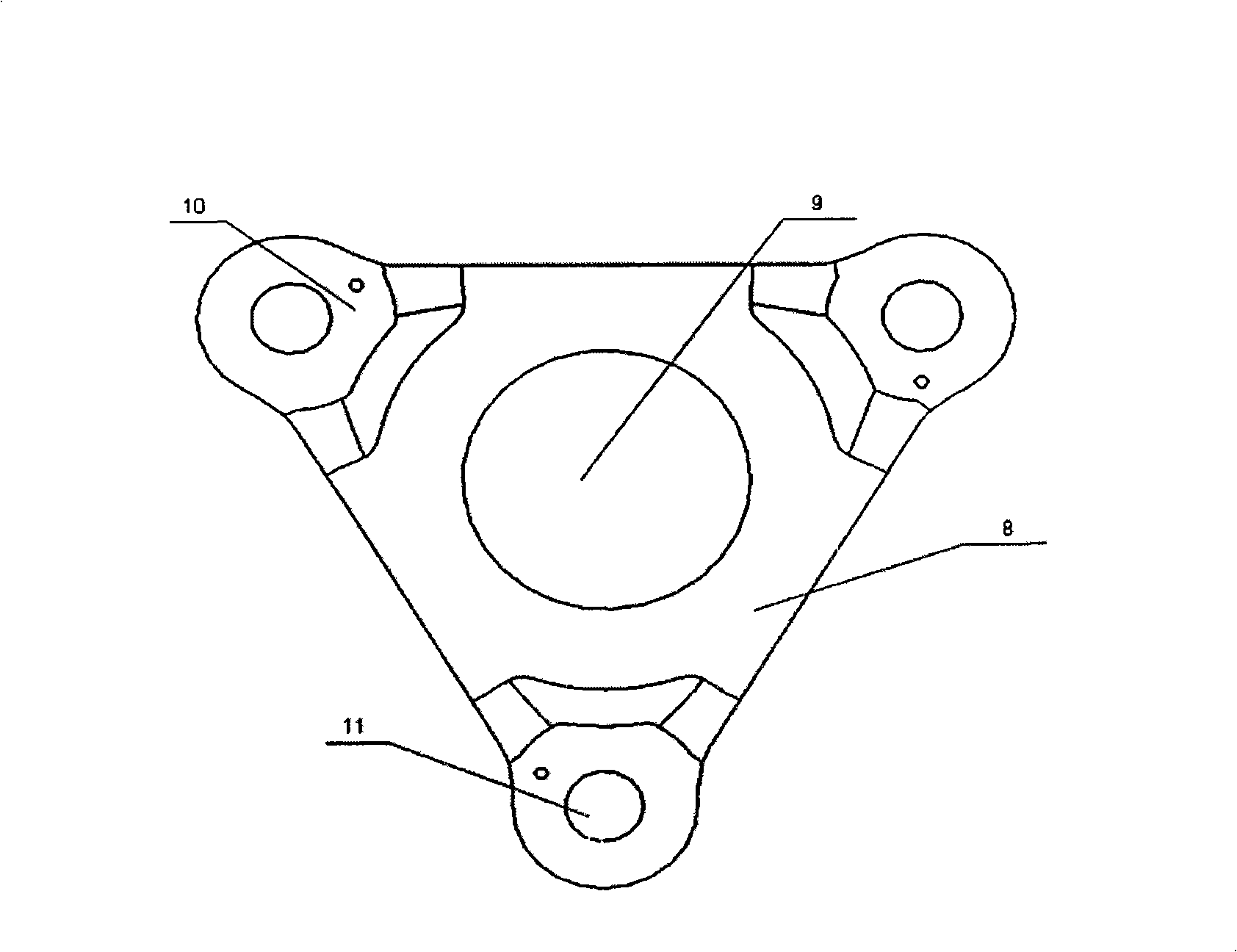

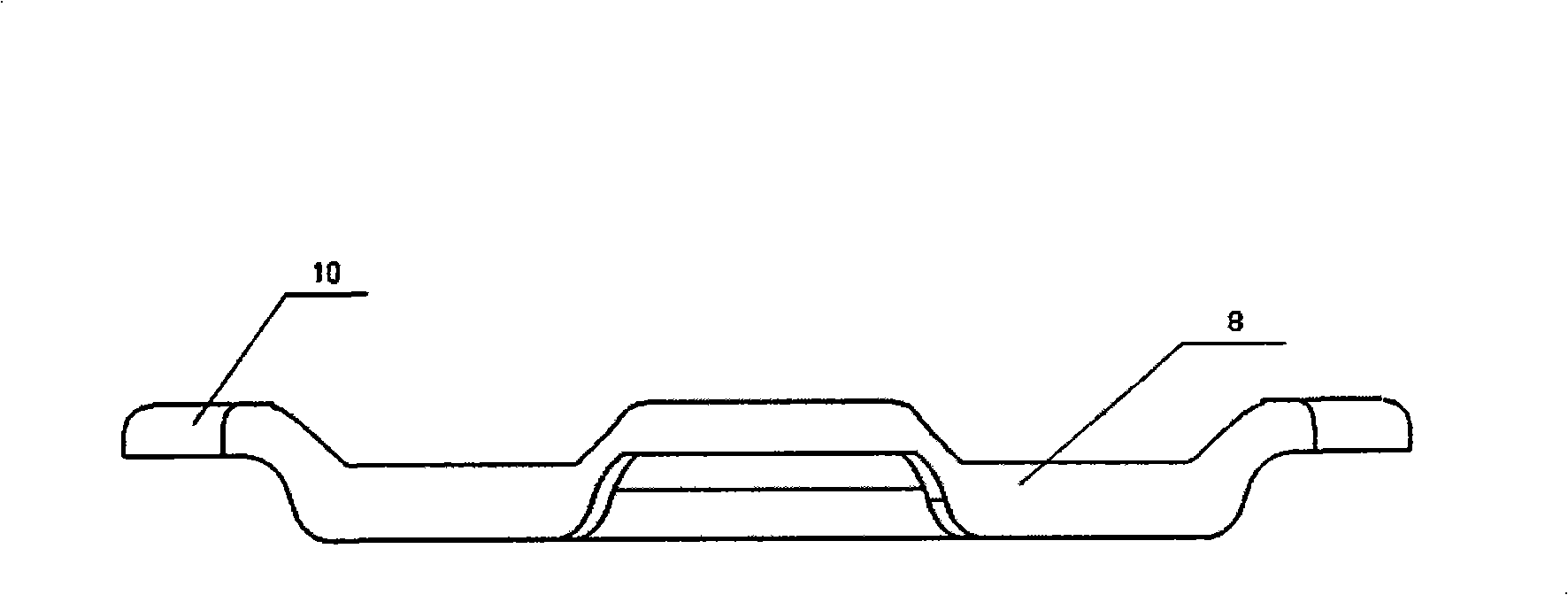

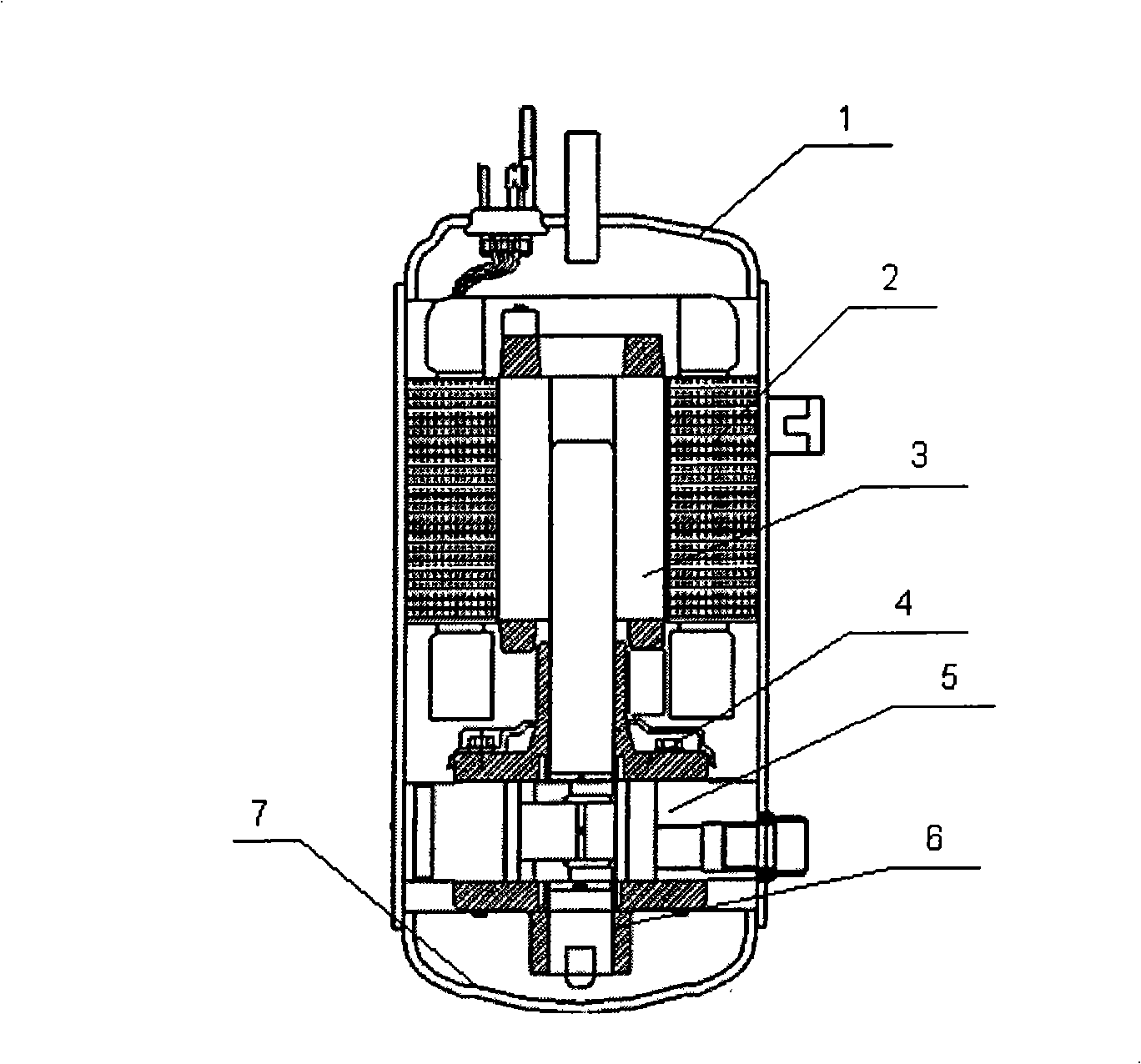

[0035] The compressor where the vibration damping base angle of the present invention is located, such as Figure 7 , 8 As shown, the compressor is composed of a casing, a power generation part, a compression part and a variable capacity part, and the power generation part, the compression part and the variable capacity part are located inside the casing. The power generation part is located at the upper part of the compressor, and the compression part is located at the lower part of the compressor, but their positions can also be exchanged as required. The upper part and the lower part of the casing are respectively equipped with a loam cake 1 and a lower cover, thereby forming a closed space inside the casing. A suction pipe used to suck the driving fluid is installed on one side of the casing, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com