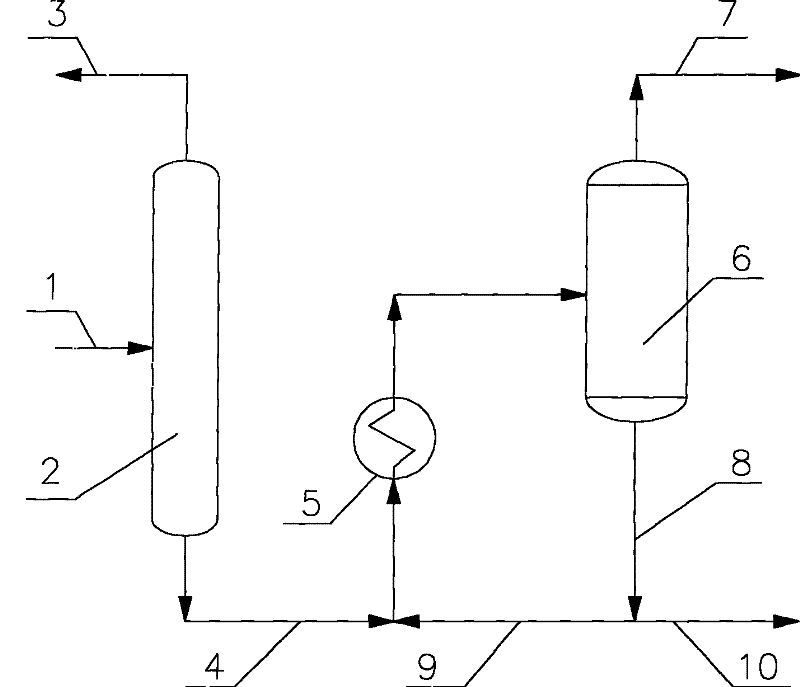

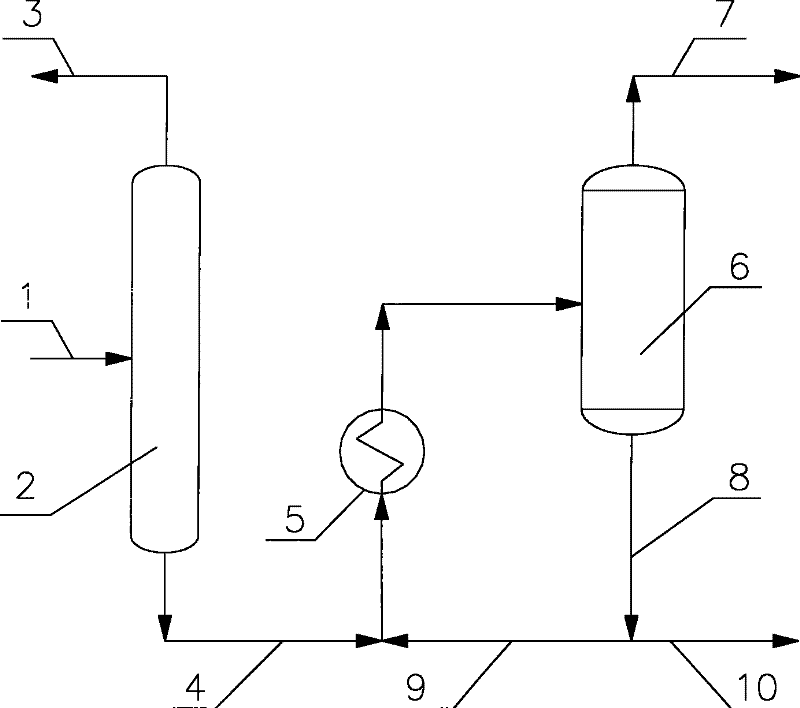

Process for recovering ethylene in process of ethylene preparation by ethanol dehydration

A technology for ethanol dehydration and ethylene, applied in organic chemistry, distillation purification/separation, etc., can solve the problem of large ethylene loss, achieve the effect of reducing the amount of ethylene and increasing the flash energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Crude ethylene from the ethylene drying system enters the ethylene rectification tower for separation. The ethylene containing light components is separated at the top of the tower, and the heavy components are separated at the bottom of the tower. The flow rates of each component are: ethylene 27.1 kg / h, ethane 745.5 kg / hour, acetaldehyde 9.2 kg / hour, ether 126.1 kg / hour, heavy component 185.8 kg / hour, wherein ethylene accounts for 2.48% (weight). After the mixture is heated to a certain temperature by the heater, it enters the middle of the flash tank for adiabatic flash evaporation. The temperature of the flash tank is 30°C and the pressure is 2.7MPaG. The material circulation enters the lower part of the ethylene rectification tower, and the flow rate of each component is: 26.8 kg / hour of ethylene, 314.5 kg / hour of ethane, 1.2 kg / hour of acetaldehyde, 18.1 grams / hour of ether, and 43.6 kg / hour of heavy components, of which Ethylene accounts for 6.64% by weight. The...

Embodiment 2

[0016] According to the feed composition and operating steps of Example 1, change the adiabatic flash evaporation conditions, the operating temperature is -10 ° C, and the ratio of the flow of the heavy component circulating to the middle of the flash tank to the flow of the heavy component discharged is 80:1 (by weight) , then the ethylene concentration of ethylene in the heavy component output is 6.06% (weight).

Embodiment 3

[0018] According to the feed composition and operating steps of Example 1, the adiabatic flash conditions were changed, the operating temperature was 40° C., the pressure was 2.2 MPaG, and the ratio of the flow of heavy components circulating to the middle of the flash tank to the flow of the heavy components was 120: 1 (weight), then the ethylene concentration of ethylene in the heavy component discharge is 1.72% (weight).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com