Adiabatic flash method for styrene tar oil

An adiabatic flash evaporation, styrene technology, applied in chemical instruments and methods, organic chemistry, hydrocarbon purification/separation, etc., can solve the problems of large loss of styrene, poor evaporation effect, high equipment investment, and achieve flash evaporation energy. The effect of improving, increasing liquidity, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

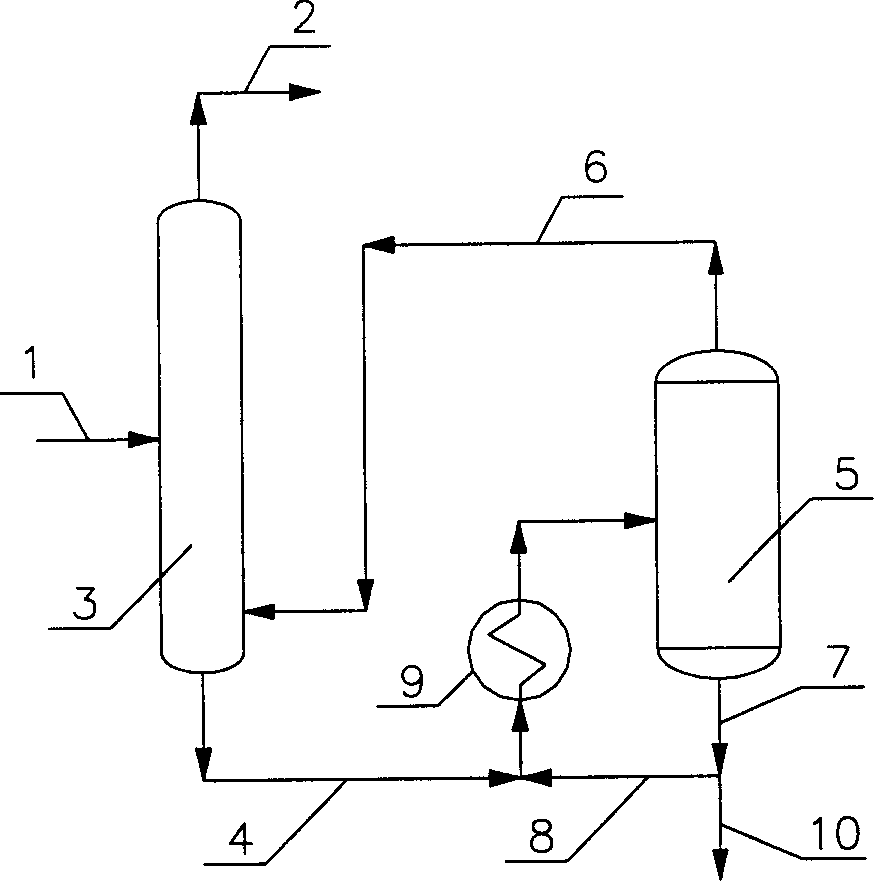

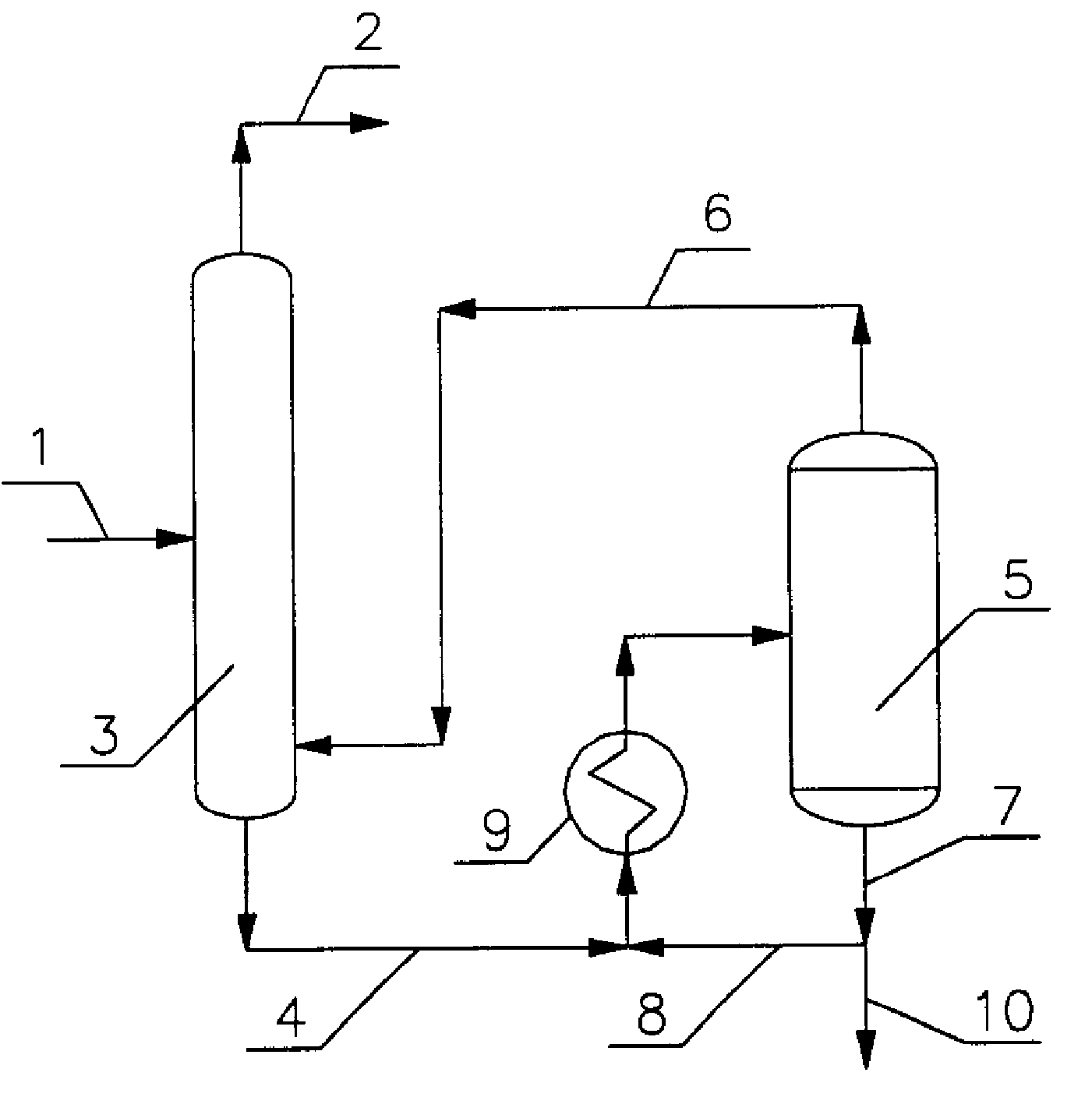

Image

Examples

Embodiment 1

[0019] The material from the bottom of the crude styrene separation tower enters the styrene separation tower for separation, and the refined styrene product is separated at the top of the styrene separation tower. A mixture of 0.03 kg / hour of cumene, 103.38 kg / hour of α-methylstyrene, 141.03 kg / hour of heavy components and 136.78 kg / hour of polymer, wherein the weight percentage concentration of styrene is 54.47%, and the mixture is passed through The heat exchanger enters the middle of the flash tank for adiabatic flash evaporation. The temperature of the flash tank is 145°C and the pressure is 20KPa. After adiabatic flash evaporation, the material mainly containing styrene is flashed from the top of the flash tank and recycled into styrene separation. In the lower part of the tower, its mass flow composition is: 444.47 kg / h of styrene, 0.03 kg / h of cumene, 99.01 kg / h of α-methylstyrene, 75.24 kg / h of heavy components and 67.78 kg / h of polymer. The discharge at the bottom of...

Embodiment 2

[0021] According to the conditions and steps of embodiment 1, just changing the operating temperature of the flash tank is 120 ℃, and the operating pressure is 30KPa, and the amount of tar in the middle part of the flash tank is circulated by weight ratio: the tar amount discharged is 140: 1, then out The weight percent concentration of styrene in the material tar is 4.98%.

Embodiment 3

[0023] According to the conditions and steps of embodiment 1, just changing the operating temperature of the flash tank is 140 ℃, and the operating pressure is 15KPa, and the amount of tar in the middle part of the flash tank is circulated by weight ratio: the tar amount discharged is 130: 1, then out The weight percent concentration of styrene in the material tar is 3.69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com