Energy-saving explosion-proof drying furnace and its drying monitoring system

A drying furnace, explosion-proof junction box technology, applied in drying, dryer, furnace and other directions, can solve the problems of lack of monitoring and control of temperature and pressure, affecting work efficiency, inconvenient operation, etc., to eliminate hidden dangers of explosion , The effect of reducing start-up time and avoiding explosion accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

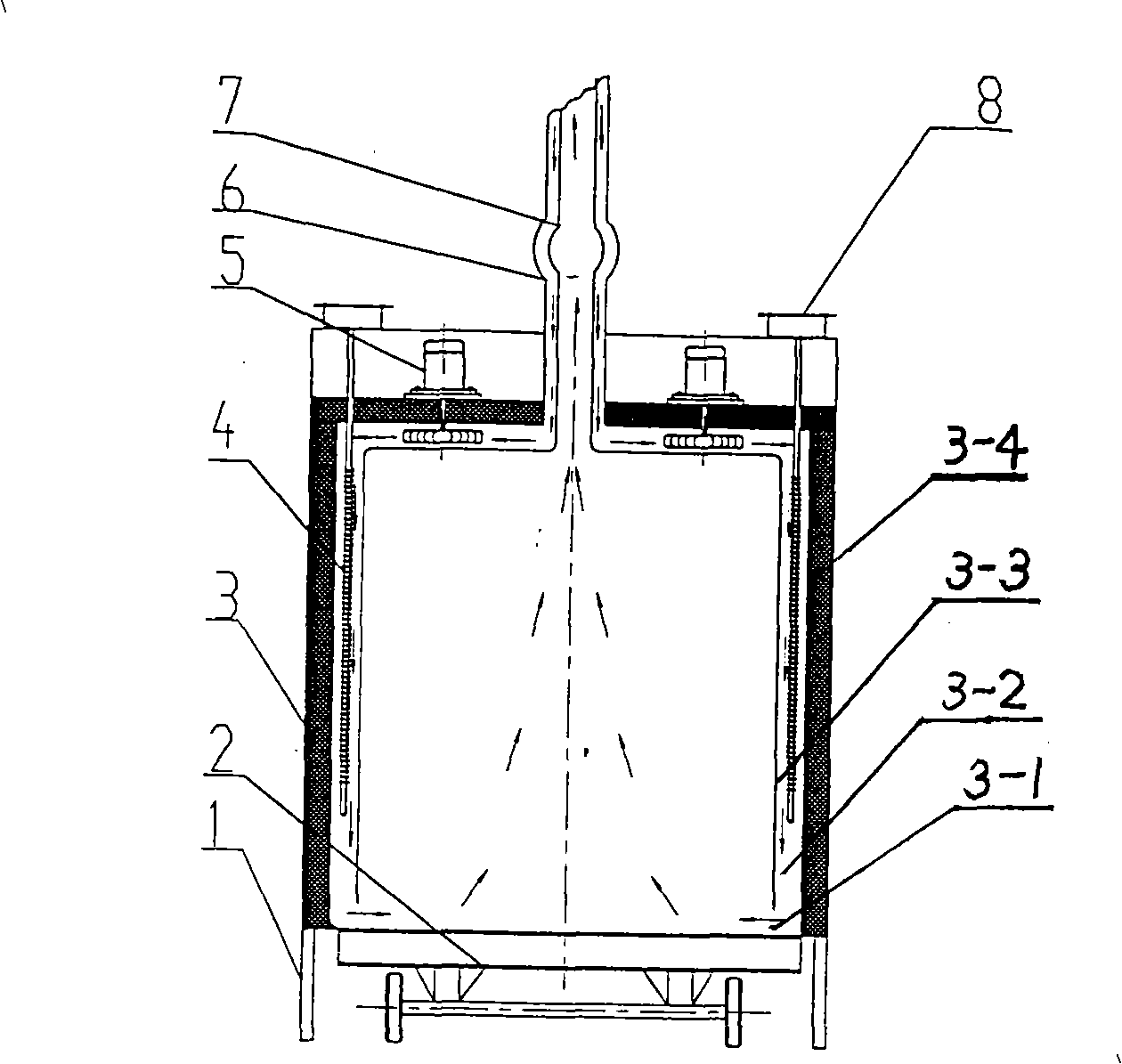

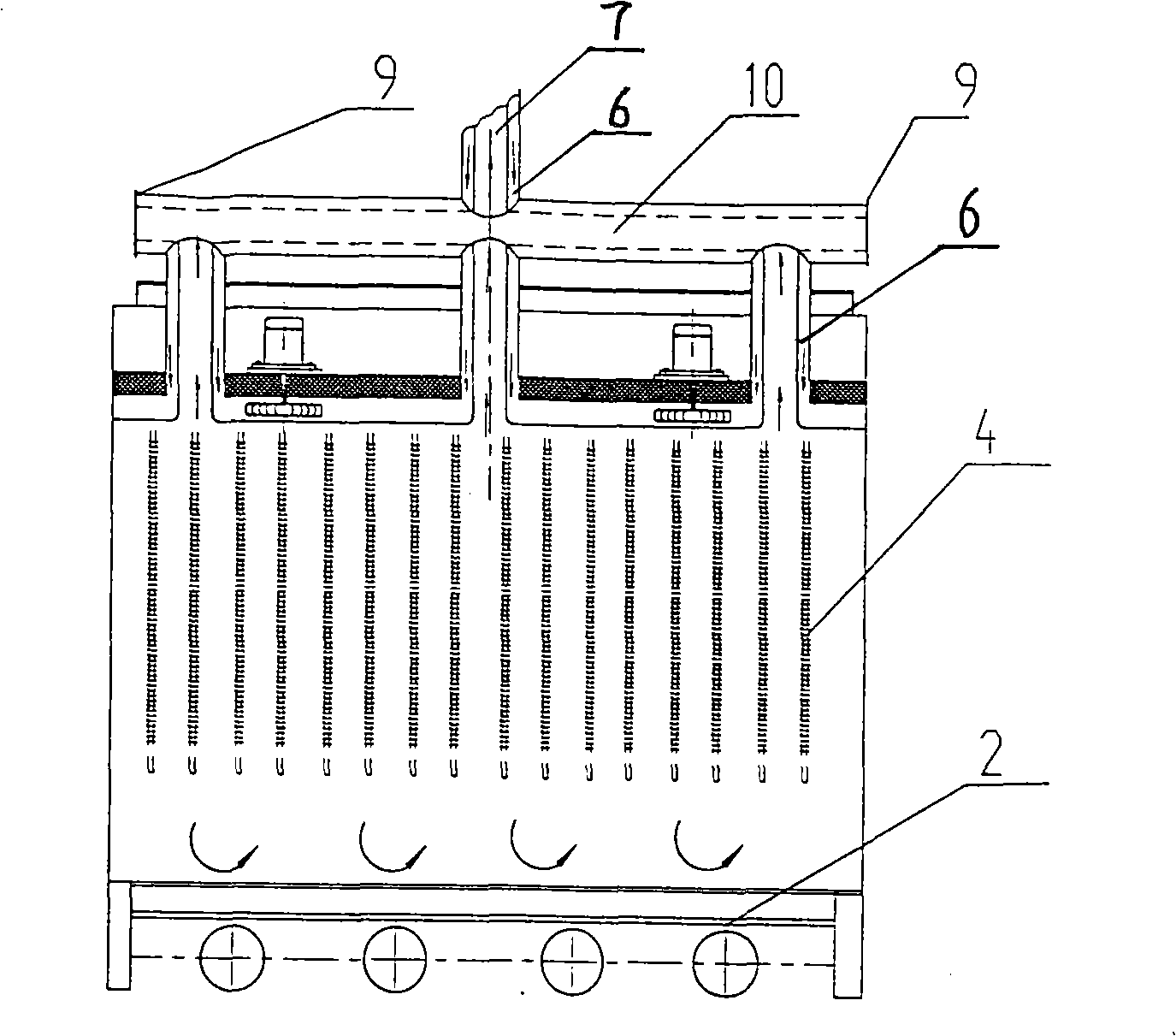

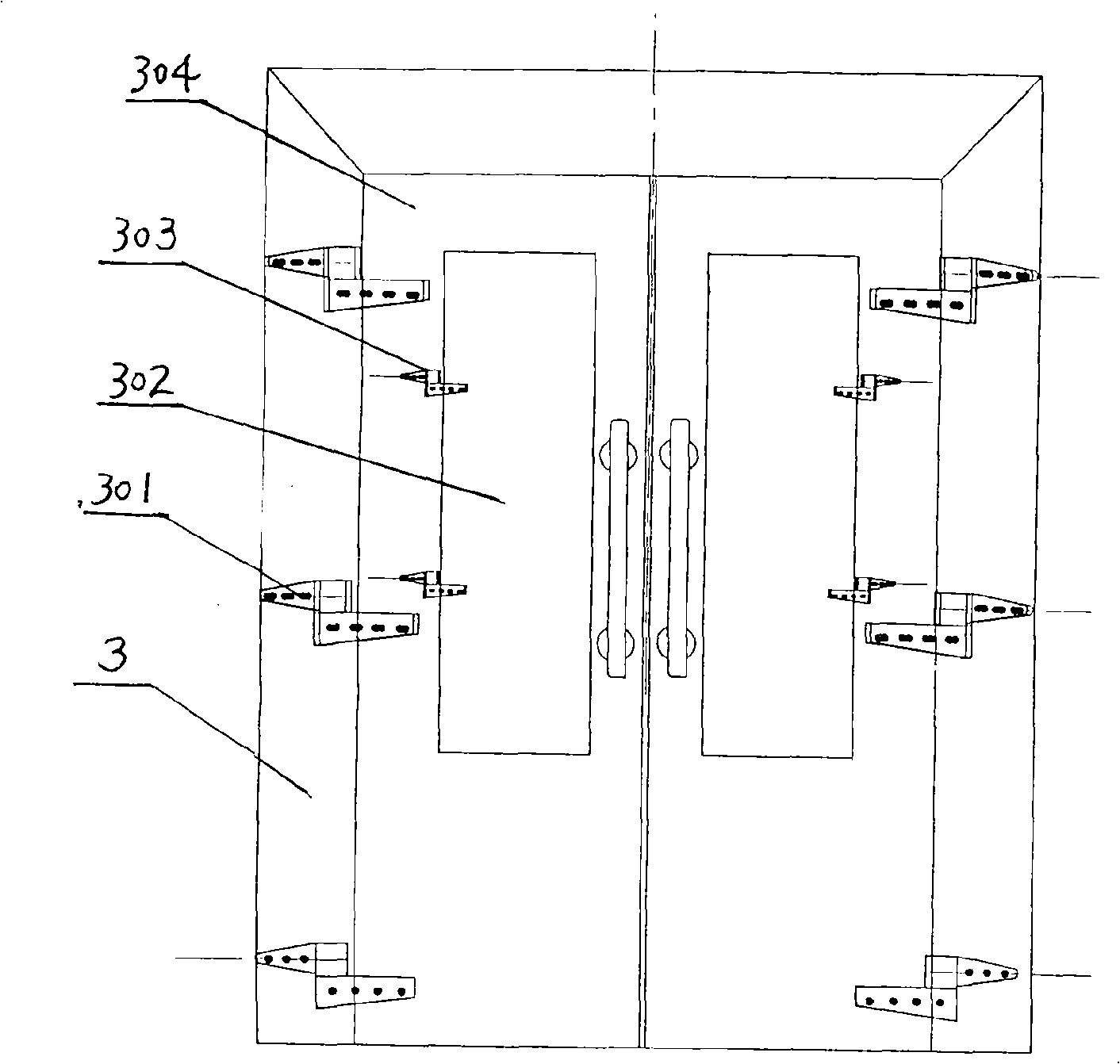

[0046] see figure 1 , figure 2The energy-saving explosion-proof drying furnace of the present invention has a box-type furnace body 3 with an inner wall 3-4 of insulating cotton, and a plurality of rows of heating tubes 4 arranged in parallel on the inner wall 3-4 of the furnace, which are positioned at the bottom of the inner cavity of the furnace and can be The load-bearing trolley 2 that goes in and out and is positioned at the chimney 7 above the body of heater top. Wherein, the furnace body is provided with a lining wall 3-3, and the gap between the lining wall 3-3 and the inner wall of the furnace body 3-4 forms a heating chamber 3-2, and the heating pipe 4 is located at the heating chamber on both sides of the furnace body. In the cavity 3-2, a hot air outlet 3-1 is provided at the corresponding position between the heating cavity 3-2 and the bottom of the furnace body 3, so that the fresh air heated by the heating cavity 3-2 can flow out from the hot air at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com