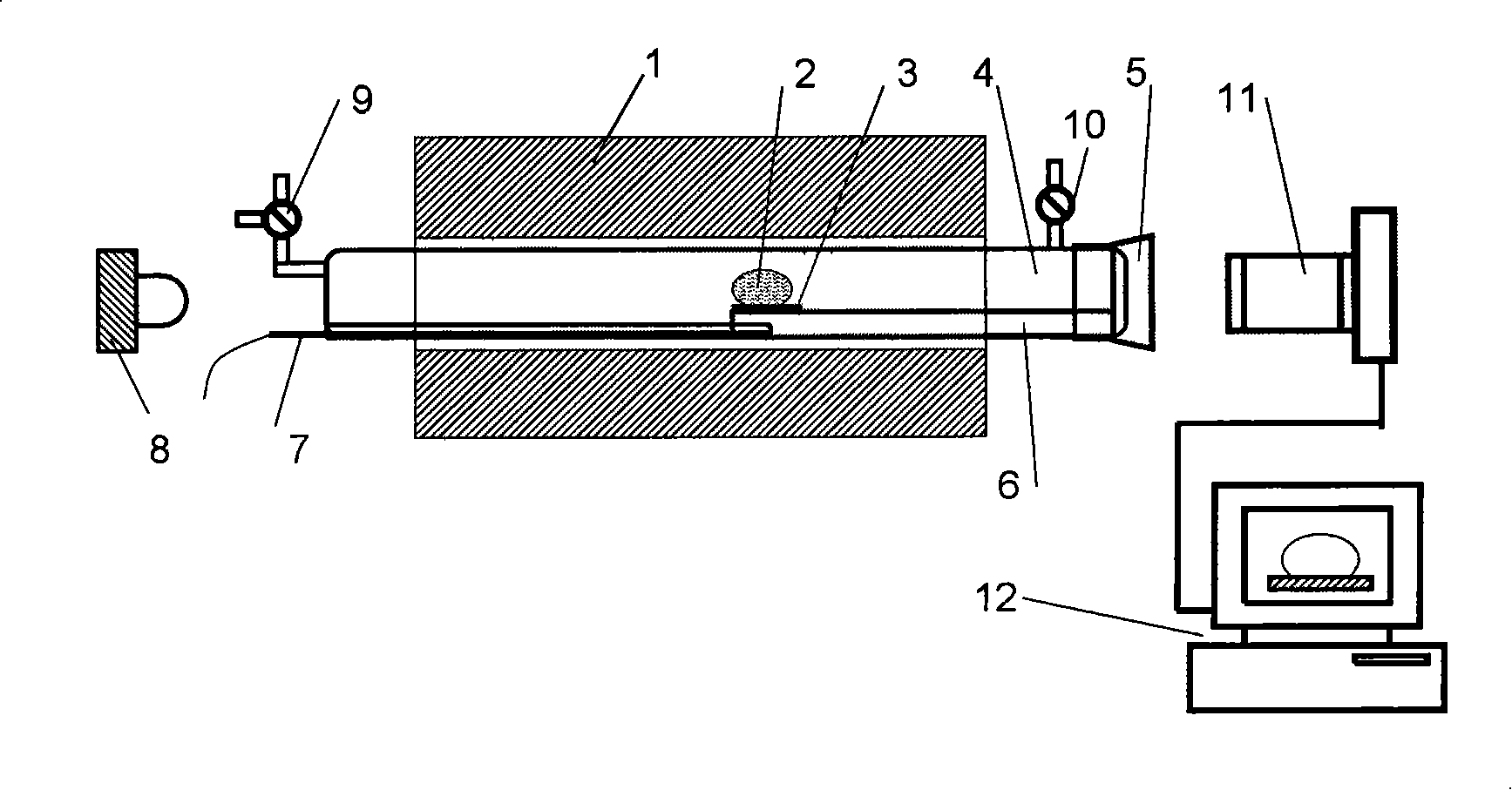

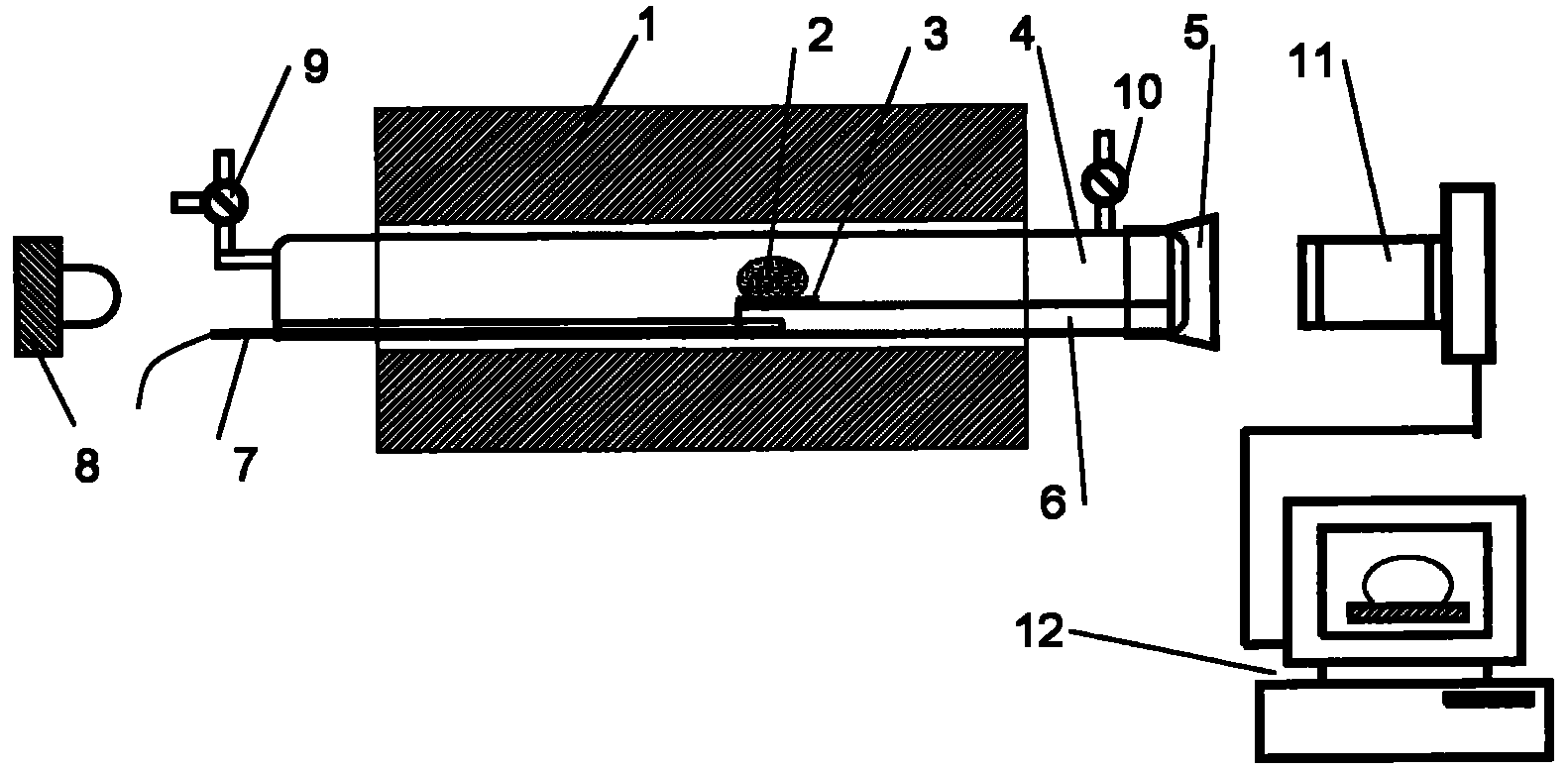

Apparatus and method for measuring middle and low-temperature smelt surface tension, density and wettability

A technology of surface tension and low temperature melt, which is used in density and wettability devices to measure the surface tension of medium and low temperature melts. Good, low equipment cost, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Measuring the surface tension of AlSi alloy.

[0022] The cylindrical sample 2 has a diameter of 8 mm and a height of 8 mm. It is placed on the surface of the high-purity graphite sheet substrate 3 and placed on the end of the sample sending quartz boat 6 together, and is sent into the quartz tube body 4 . Put Ti powder on the sample sending quartz boat 6 as oxygen scavenger. Adjust the sample sending quartz boat 6 so that the sample substrate remains horizontal, and finally seal it with a quartz glass cover 5 . Then use an external vertical leveler combined with the substrate image on the computer to judge whether the substrate 3 is tilted, rotate the quartz glass tube body 4, and observe the substrate image on the computer at the same time, so that the substrate is in a completely horizontal position.

[0023] High-purity argon / hydrogen mixed gas is used as the protective atmosphere during the measurement. First close the two-way air inlet 10, adjust the ...

Embodiment 2

[0025] Example 2: Measuring the wettability of lead-free binary Sn-based alloys with metal Cu.

[0026]A cylindrical sample 2 with a diameter of 6 mm and a height of 8 mm is placed on the surface of an oxygen-free Cu substrate 3 and placed together at the end of a sample sending quartz boat 6 , and sent into the quartz tube 4 . Put Ti powder on the sample sending quartz boat 6 as oxygen scavenger. Adjust the sample sending quartz boat 6 so that the sample substrate remains horizontal, and finally seal it with a quartz glass cover 5 . Then use an external vertical leveler combined with the substrate image on the computer to judge whether the substrate 3 is tilted, rotate the quartz glass tube body 4, and observe the substrate image on the computer at the same time, so that the substrate is in a completely horizontal position.

[0027] The flow protection atmosphere of high-purity argon / hydrogen mixed gas can be used for measurement, and vacuum atmosphere can also be used. Fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com