High-sensitivity ultrasonic probe

A high-sensitivity, ultrasonic technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc. Meet the requirements of non-destructive testing and other problems, and achieve the effect of small detection blind spot, high sensitivity, easy accurate positioning and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

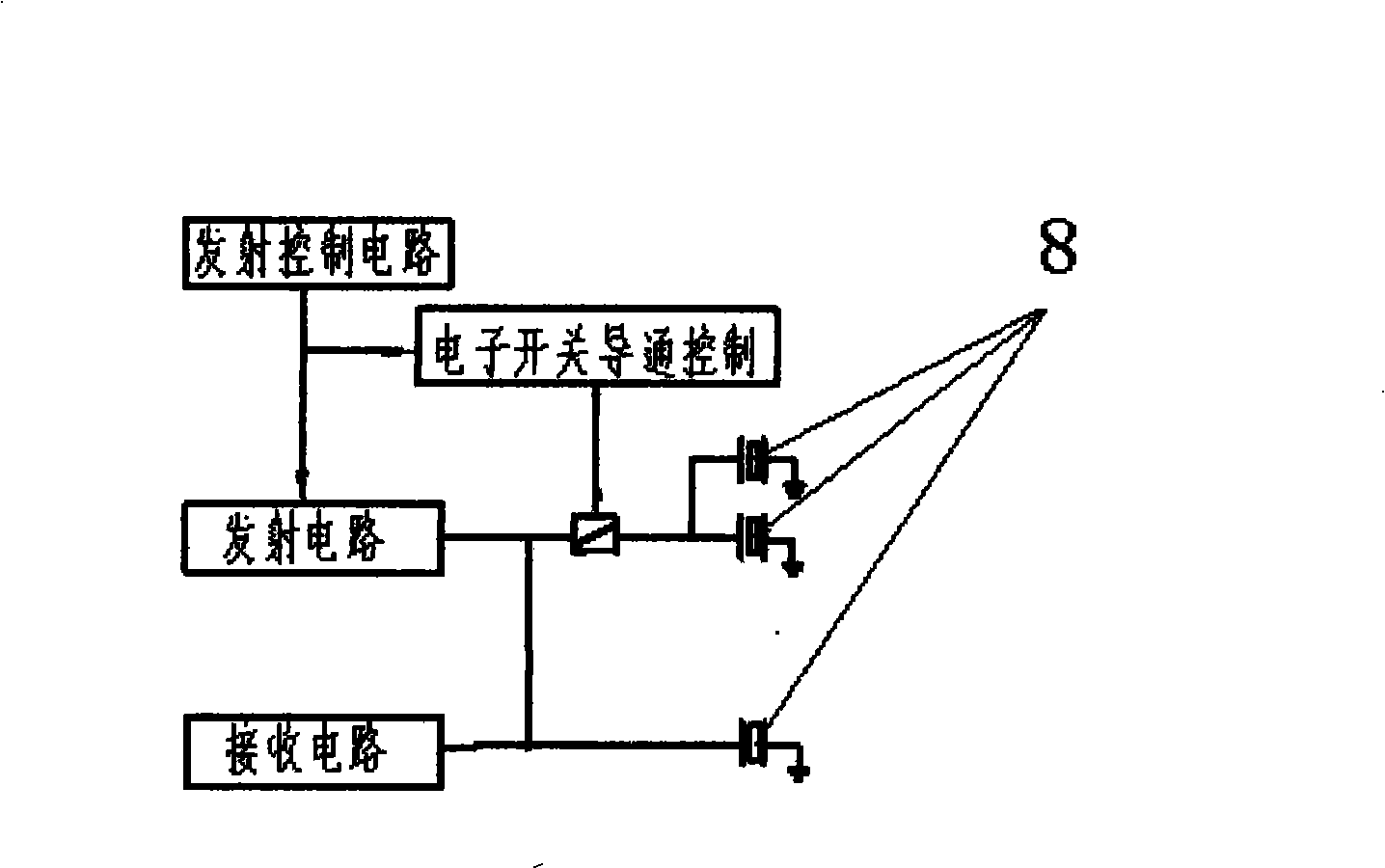

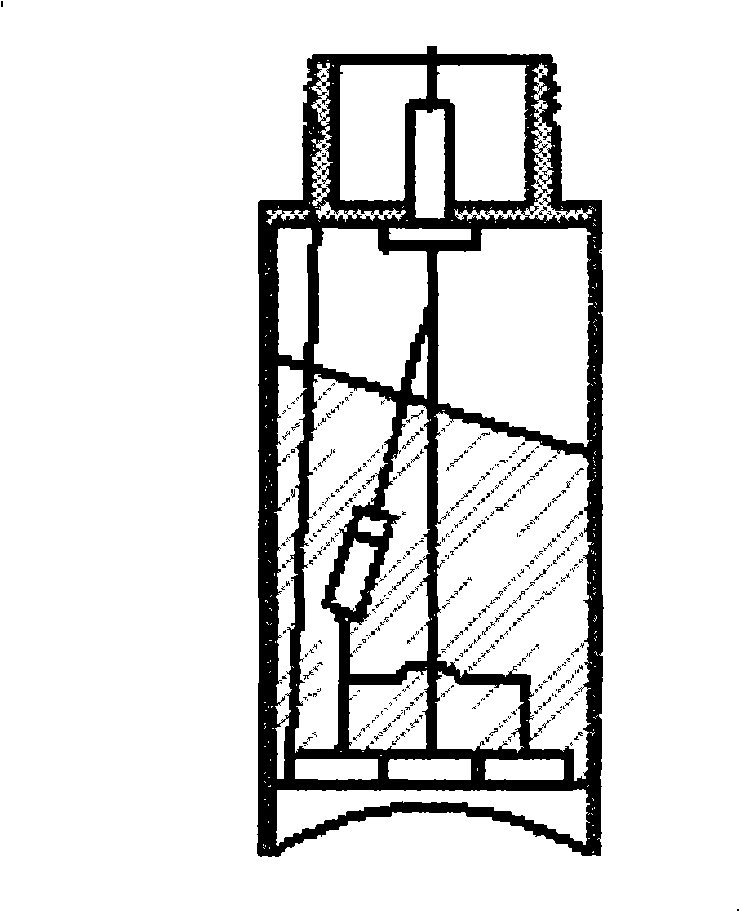

[0034] TTR straight probe

[0035]In ultrasonic flaw detection, for example, when testing forgings, the larger the diameter of the piezoelectric chip in the probe, the smaller the spread angle, the smaller the spread of the ultrasonic signal, and the better the directivity of the sound beam. Therefore, the ring chip and the small chip are used to emit ultrasonic waves at the same time. The echo path away from the axis of the main sound beam is longer, and its echo amplitude is relatively lower than that in the direction of the axis of the main sound beam. Chips with small diameters can only accept defect echoes in the direction of the axis of the main sound beam. , using a small chip to receive the echo of the ultrasonic wave, can more accurately locate the position and size of the defect. Therefore, in the flaw detection of forgings, the use of large-diameter chips to emit and small-diameter chips to receive improves the accuracy of the probe for defect positioning, and can ...

Embodiment 2

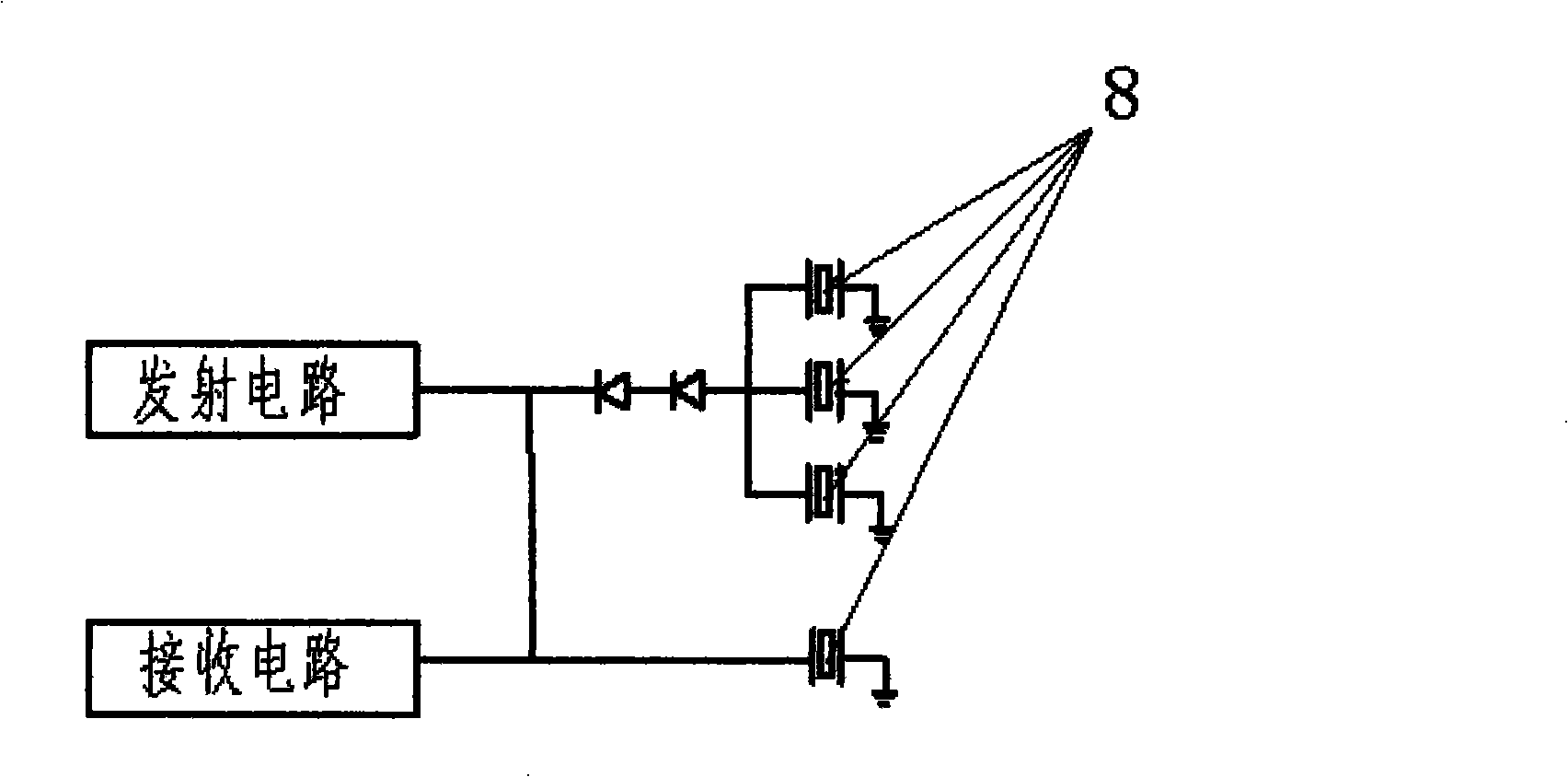

[0037] A TTR water immersion point focused ultrasonic probe

[0038] In water immersion focused ultrasonic flaw detection, for example, when detecting aviation small-diameter pipes, especially when detecting small-diameter thin-walled pipes, there is no ideal probe at home and abroad. This is because in the previous probe design, according to the theoretical and experimental results, the diameter of the focused focal cylinder is d ≈ F · λ D , Where F is the focal length, λ is the wavelength in water, and D is the diameter of the wafer. Under certain detection conditions, F should not be too small. In order to obtain a good focusing effect, the only way to increase the diameter of the wafer is. However, when the ultrasonic beam reaches the surface of the tube, there will inevitably be diffuse reflection, among which the reflection echo of the main beam axis is the strongest, and the...

Embodiment 3

[0041] TTR Line Focusing Probe

[0042] In civil pipe flaw detection, in order to improve detection efficiency, line focusing probes are often used. The line focusing probe is a probe that can detect defects with a certain crack length, and it scans materials or workpieces according to lines.

[0043] The present invention changes the circular or rectangular piezoelectric wafer of the line focusing probe into three rectangular wafers arranged side by side, and the three wafers are used together as a transmitting wafer, and only the middle rectangular wafer is used as a receiving wafer. With the working method described in Embodiment 2, In this way, a better focusing effect can be obtained, the detection sensitivity is improved, and the diffuse reflection echo of the interface is effectively suppressed. The rectangular chip located in the middle receives the echo on the axis of the main sound beam, which better locates the size and position of the defect, improves the resoluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com