Knife flywheel type crusher

A crusher and cutter wheel technology, applied in agricultural machinery and implements, cutting equipment, grain processing, etc., can solve the problem of unsuitable pretreatment for power generation enterprises, and achieve the effect of improving operation efficiency, stable performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

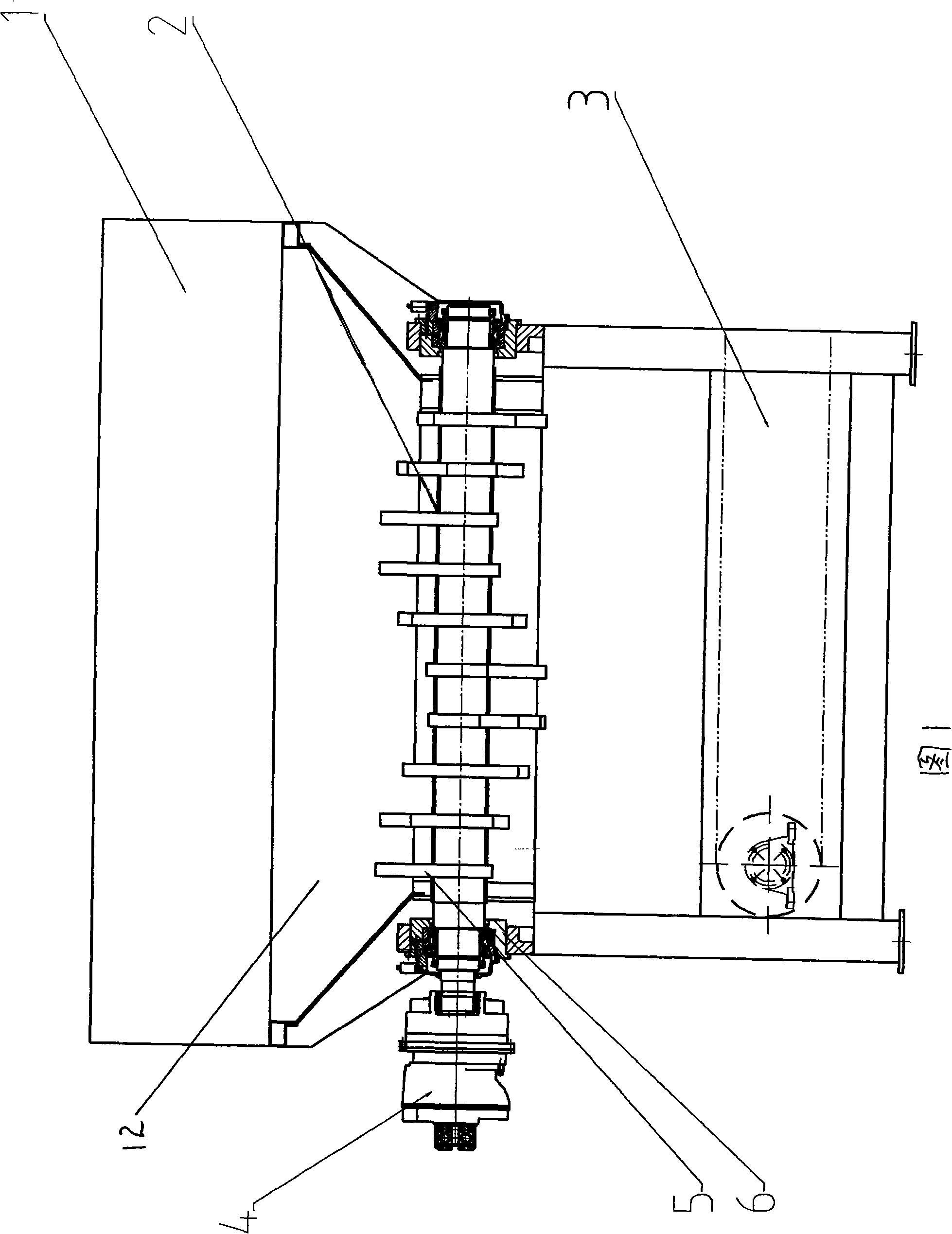

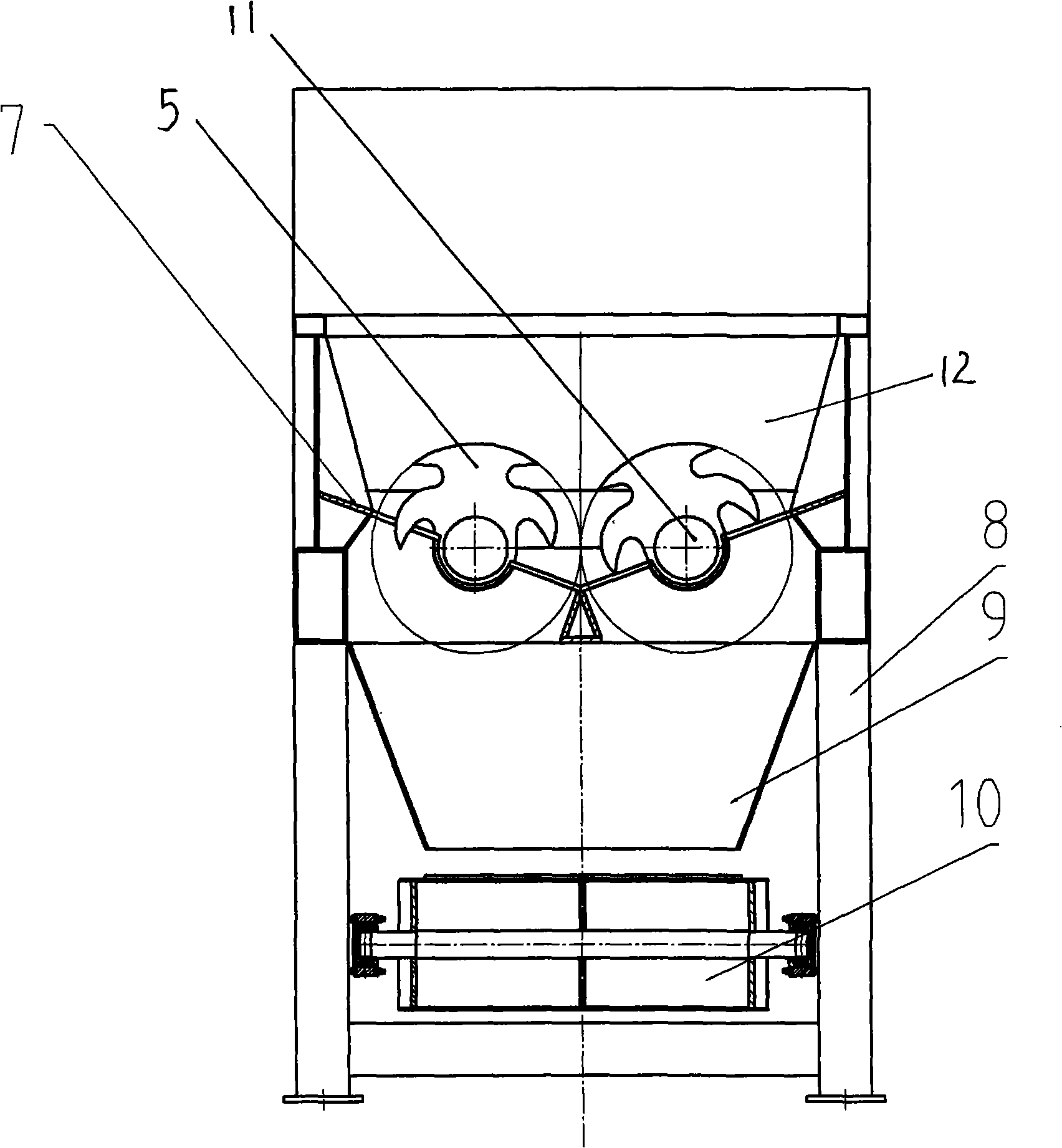

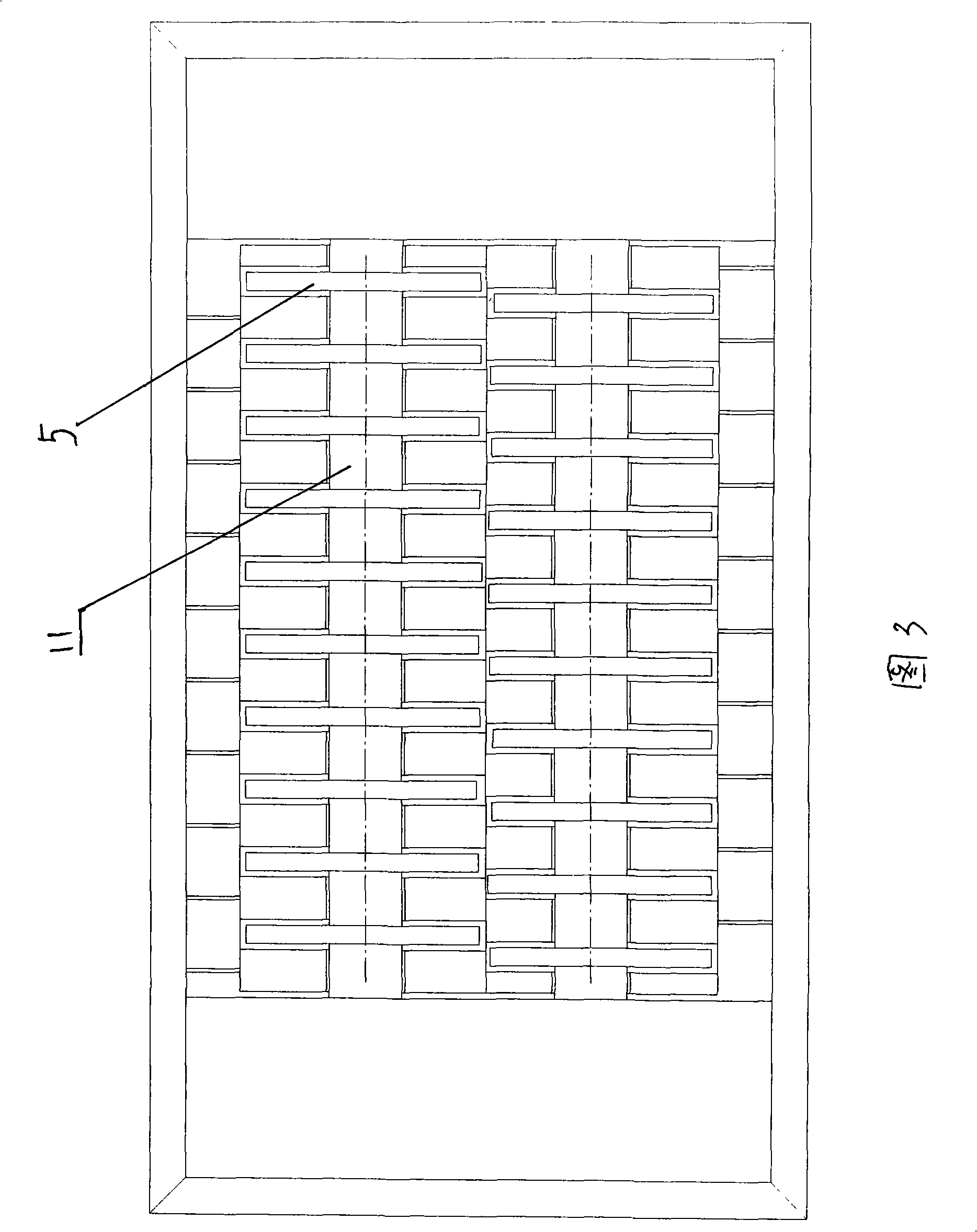

[0012] Referring to the accompanying drawings, the embodiment of the present invention has a frame 8 on which two cutter wheel and roller assemblies 2 that can be driven by a transmission device 4 are installed. The transmission device 4 is a mechanical transmission device, and may also be a hydraulic transmission device. Said cutter wheel roller body assembly 2 comprises bearing block 6 installed on the frame 8, transmission shaft 11 installed on the bearing block 6, several groups of cutter wheel blades 5 are installed on the drive shaft 11, the cutter wheel The slices 5 are helically arranged on the transmission shaft 5 . The cutter wheel 5 is provided with left and right symmetrical shifting teeth, and the shifting teeth are provided with cutting blades. The bottom of the frame 8 is connected with the lower casing 3, and the discharge passive roller 10 is installed on the frame 8 in the lower casing 3. The top of frame 8 is connected with bottom knife body 1, and this bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com