Constant temperature keeping device

A technology of constant temperature and generation device, which is used in household refrigeration devices, cooling fluid circulation devices, temperature control and other directions, can solve the problems of slow heat conduction of cold medium gas and increased burden on heaters, and achieves improved thermal responsiveness and thermal response. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

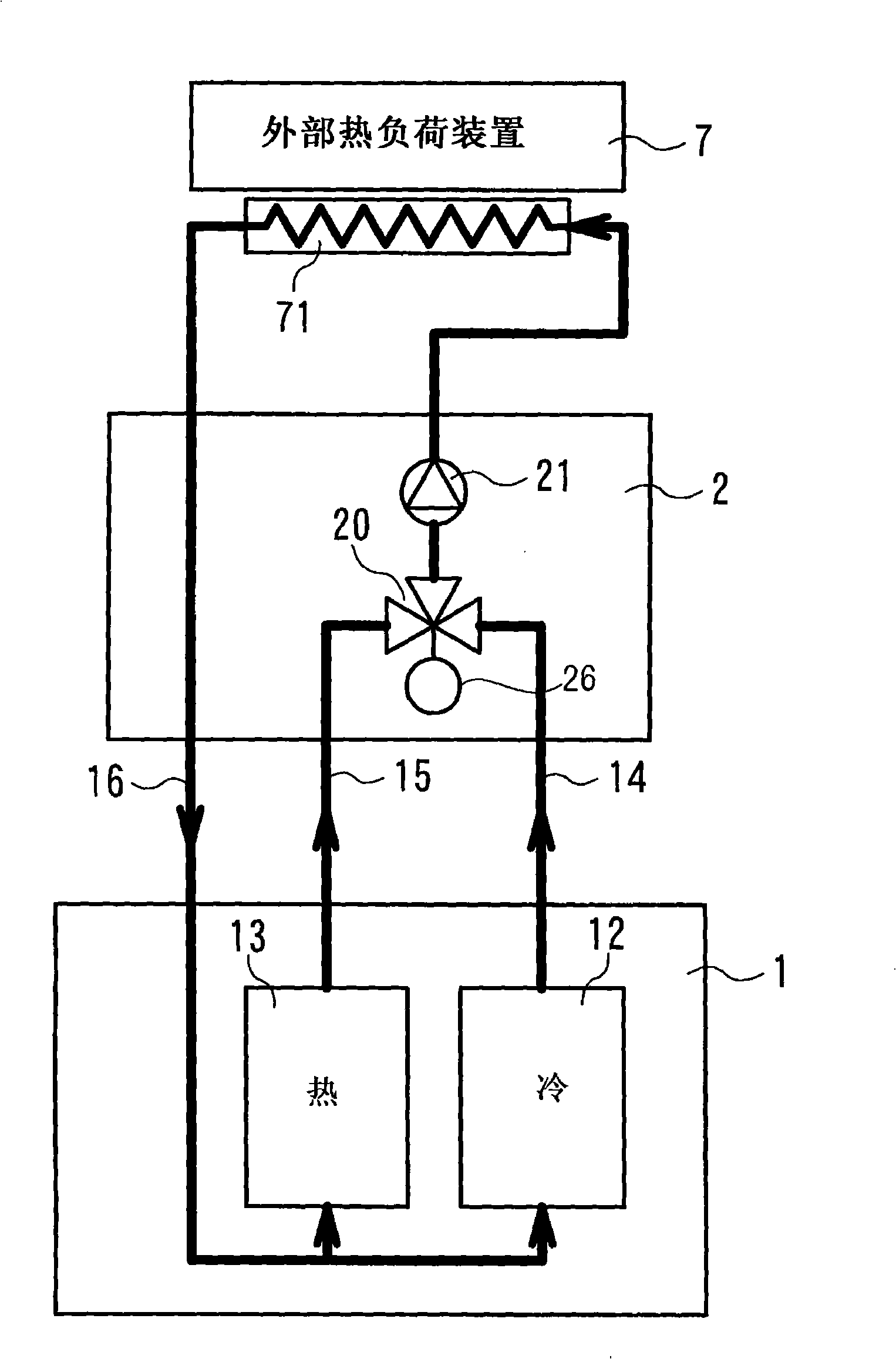

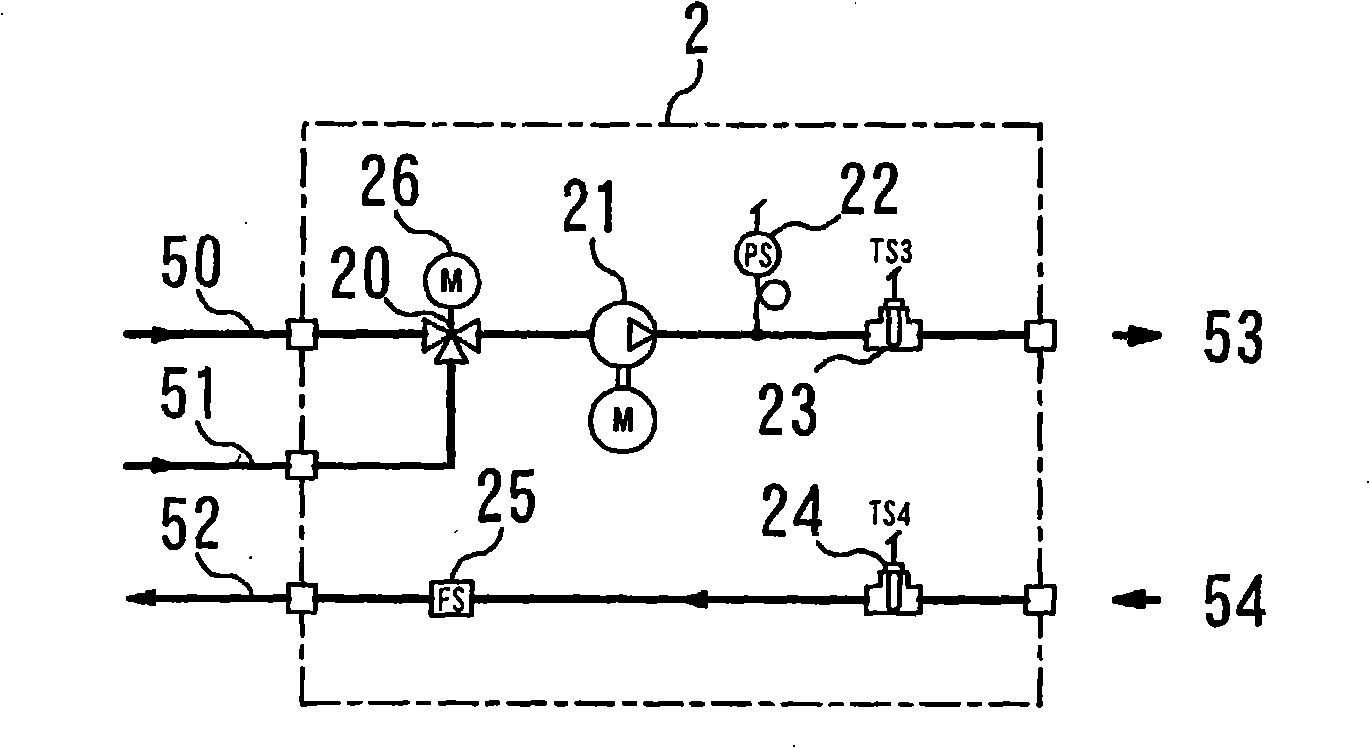

[0074] figure 1 It is a conceptual diagram showing the constant temperature maintaining device of the present invention, 1 is a main unit, 2 is an auxiliary unit, 12 is a low-temperature heat medium circulating fluid generator, 13 is a high-temperature heat medium circulating fluid generator, 20 is a three-way valve, 21 is a 26 is a control valve, 7 is an external heat load device, and 71 is a heat exchange chamber.

[0075] The low-temperature heat medium circulating fluid generated by the low-temperature heat medium circulating fluid generator 12 is supplied to the auxiliary unit through the high-temperature circulating fluid supply pipe 15 through the low-temperature circulating fluid supply pipe 14 , and the high-temperature heat medium circulating fluid generated by the high-temperature heat medium circulating fluid generator 13 is supplied to the auxiliary unit through the high-temperature circulating fluid supply pipe 15 2 three-way valve 20. The control valve 26 of th...

Embodiment 2

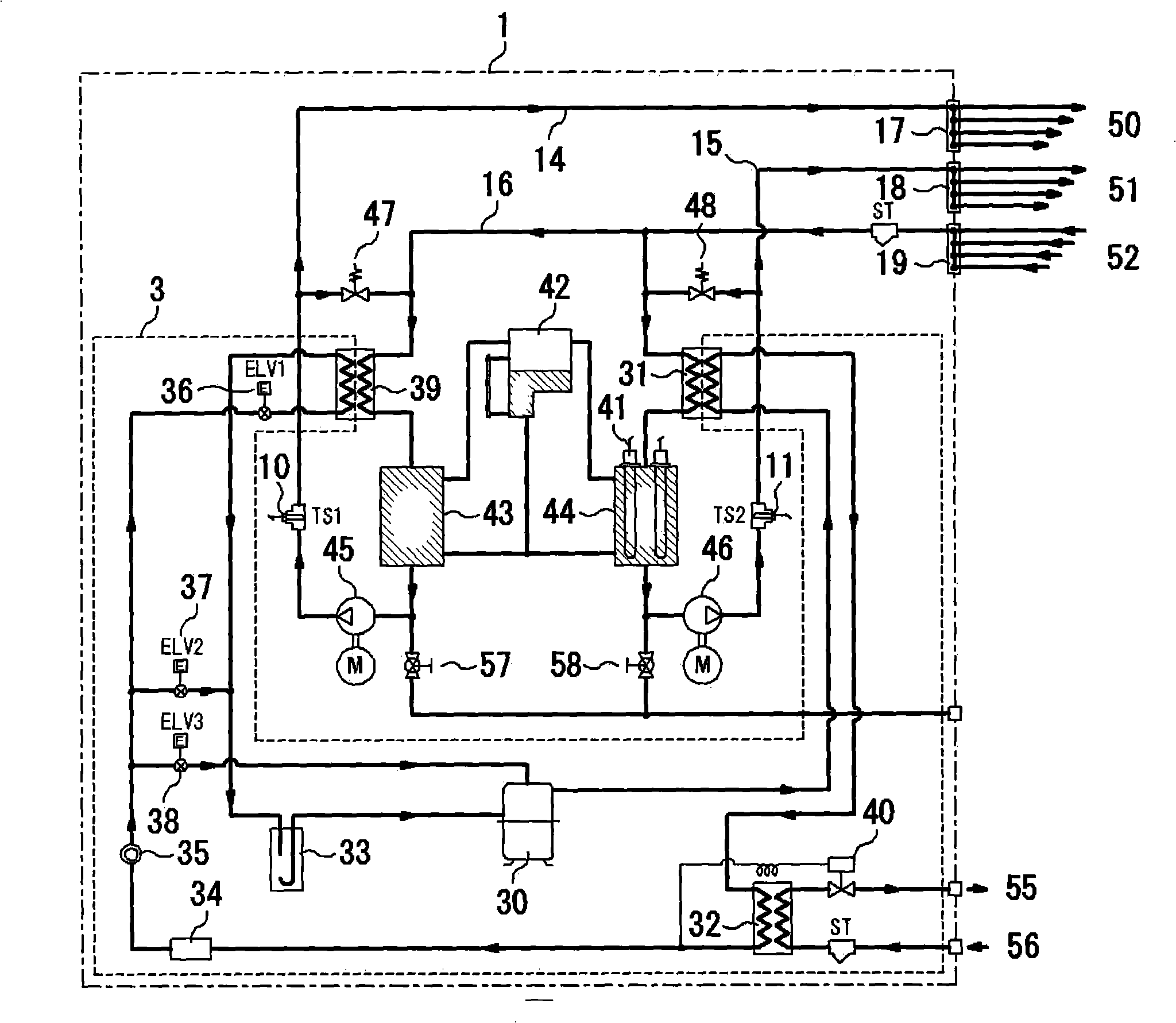

[0113] FIG. 11 shows an example in which plant water is used as a cooling source of the main unit and a heater is used as a heating source.

[0114] 4 is the factory equipment water cooling system, the factory water introduced from the cooling water inlet 56, in the equipment water heat exchanger 59, exchanges heat with the low-temperature circulating fluid returned from the auxiliary unit 2 through the pipe 16, thereby cooling Low temperature circulating fluid. The cooled low-temperature circulating fluid is stored in the cooling side tank 43 , passed through the low-temperature circulating fluid supply pipe 14 by the cooling pump 45 , and sent to the auxiliary unit 2 through the low-temperature circulating fluid auxiliary unit supply pipe 50 . The temperature of the low-temperature circulating fluid is measured by the cooling-side temperature sensor 10, and the PID controls the cooling-side heater 60 provided in the cooling-side water tank 43 until the measured temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com