Engine with double-push bar tappet rod and stand-alone interstice regulator, and air valve mechanism thereof

A technology for lash adjusters and valve trains, applied in the direction of machines/engines, engine components, mechanical equipment, etc., which can solve problems such as expensive, cost-effective, and high wear rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Those skilled in the art will appreciate that the various features of the invention shown and described with reference to any one of the drawings may be combined with characteristics shown in one or more other drawings to produce Embodiments of the invention are described. The combinations of features shown provide typical embodiments for typical applications. However, various combinations and modifications of the features consistent with the teachings of the present invention may be required for particular applications or implementations.

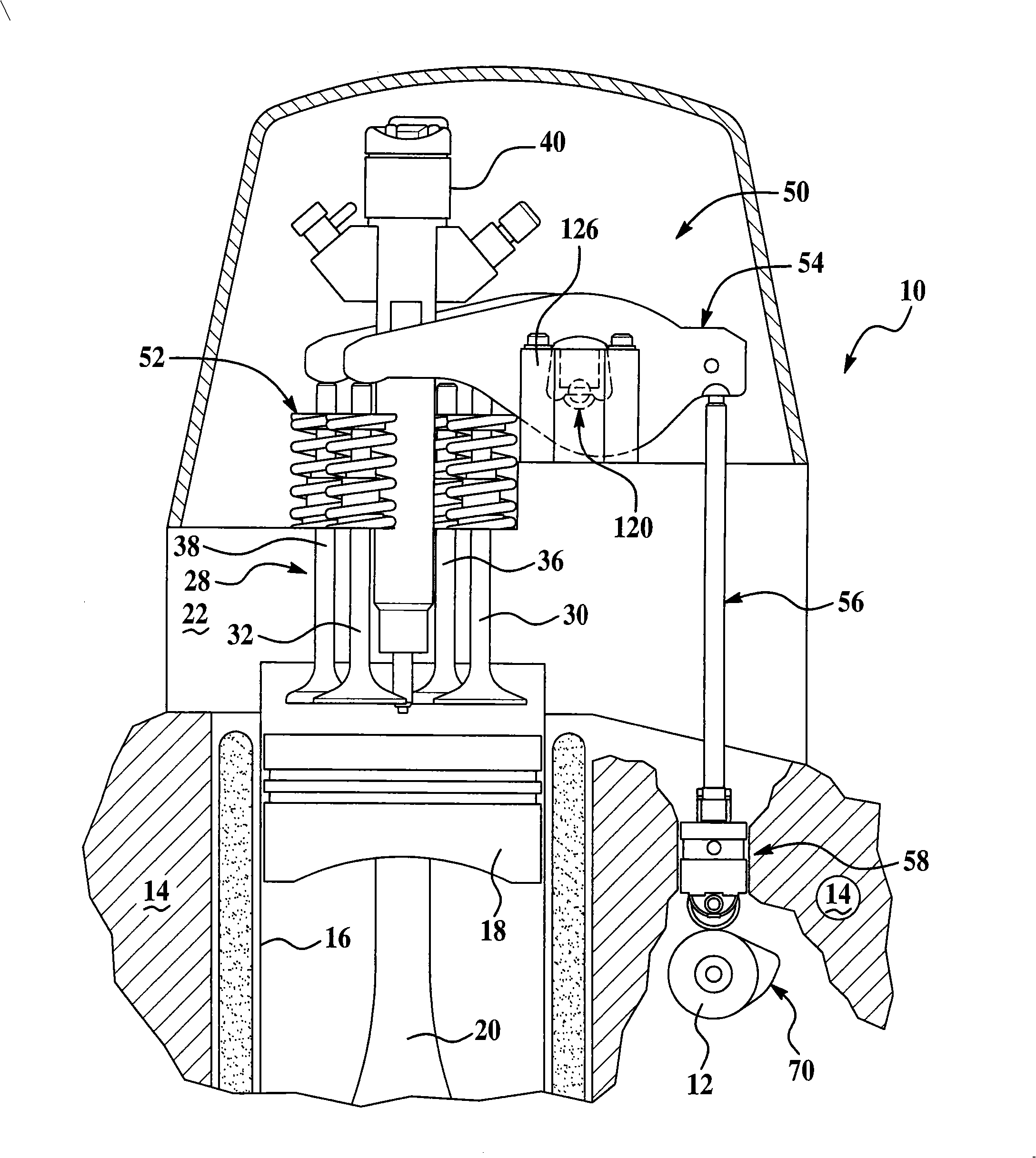

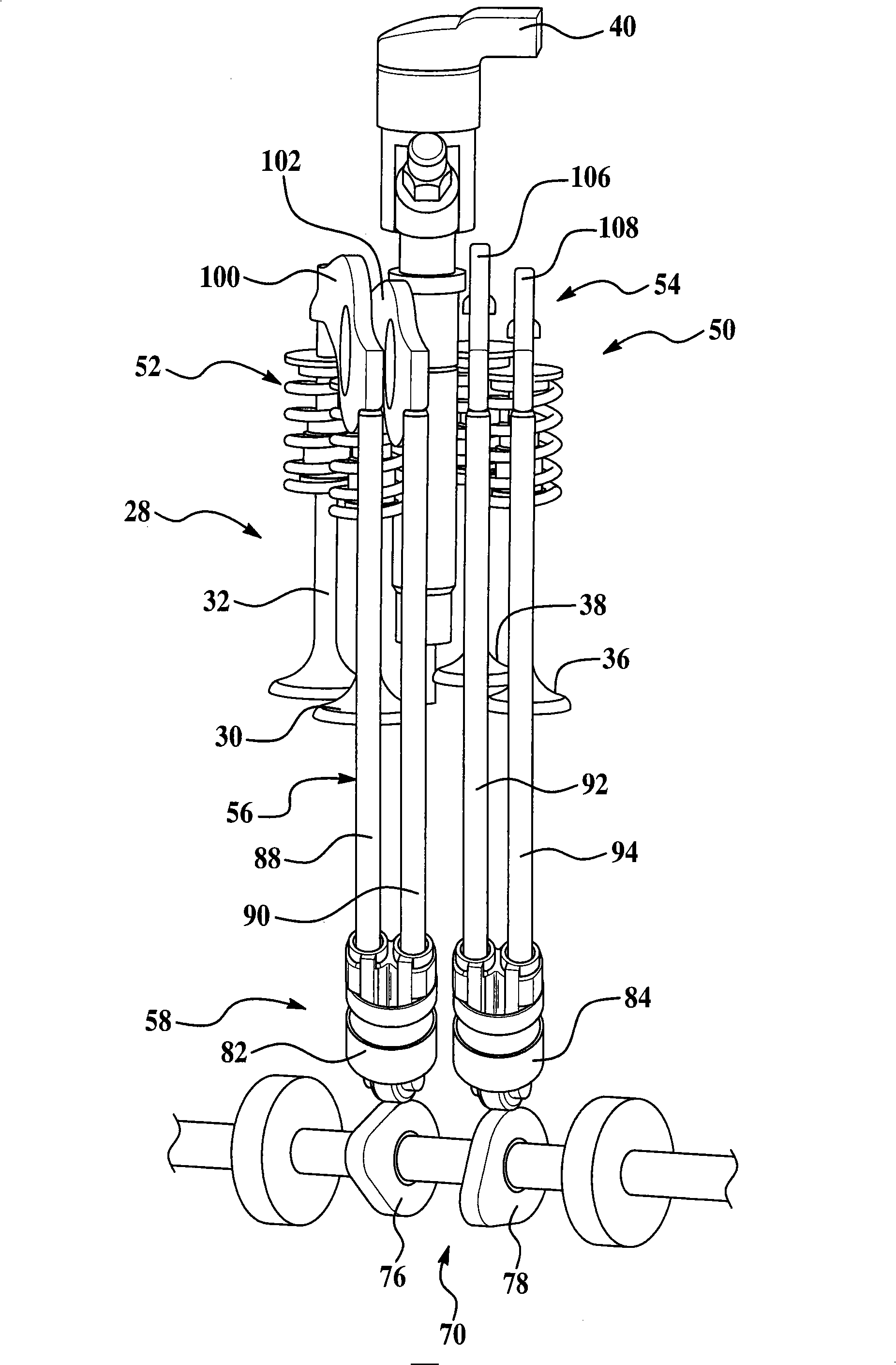

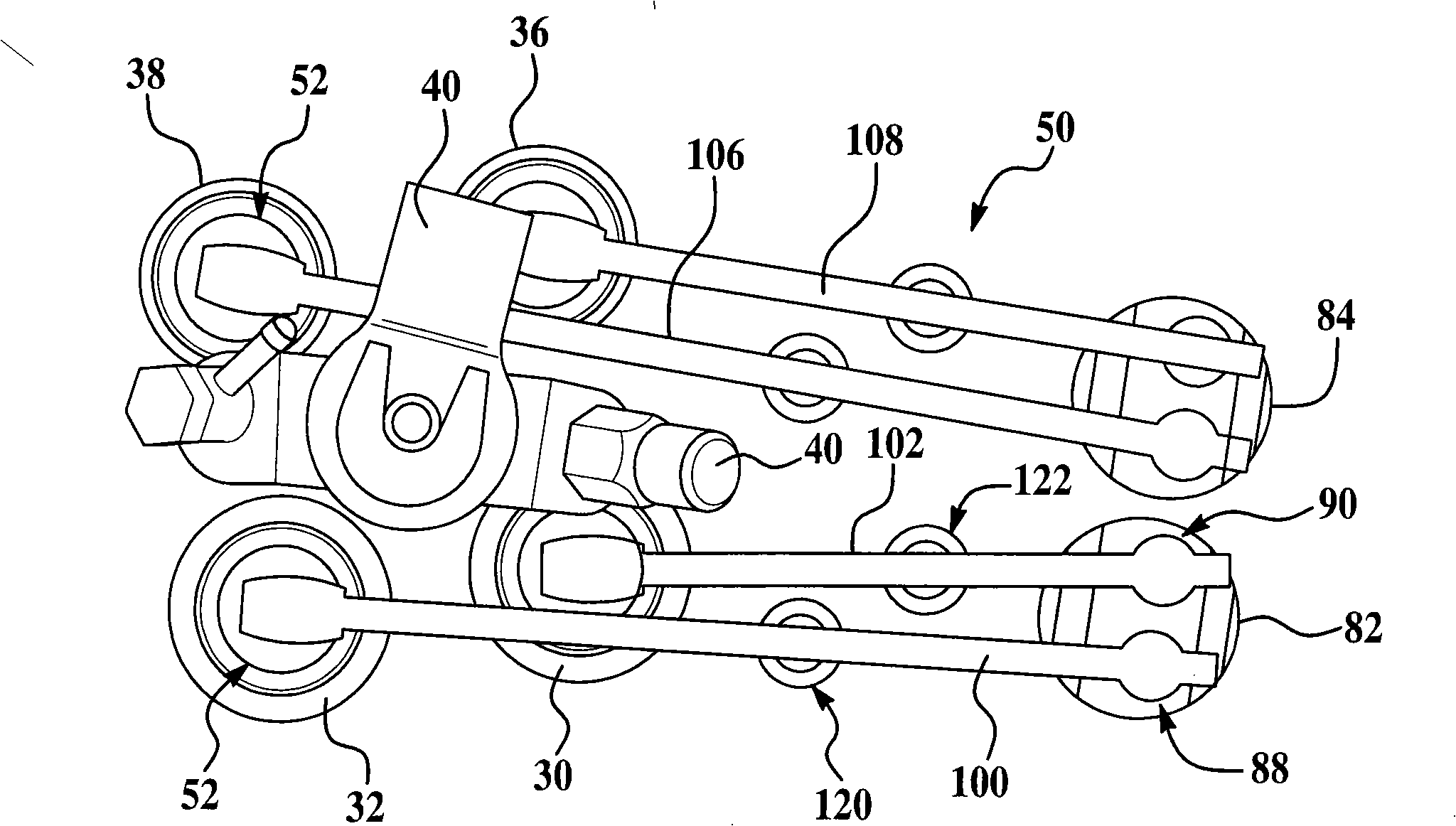

[0015] Figure 1-3 Operation of an internal combustion engine and valve train according to an exemplary embodiment of the present invention is shown. The multi-cylinder internal combustion engine 10 is generally of conventional design except for various valvetrain components as described herein. Accordingly, various conventional features associated with the engine and valvetrain are not particularly shown or described. Those ski...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com